Concrete reinforcement solutions for efficient high-rise construction

This interaction delves into how Dextra India’s product offerings accelerate high-rise construction sustainably and cost-effectively.

Can you provide an overview of the products that you offer?

Dextra Group has been on a journey of constant evolution since its inception in 1983. Through the years, the company has fostered an entrepreneurial culture, inspiring its workforce to pursue growth and innovation. This philosophy has driven the company to diversify and achieve exponential expansion.

With a global footprint, Dextra has played a pivotal role in over 15,000 major construction and industrial projects. This vast experience has enabled the company to cultivate unique expertise and a deep understanding of customers worldwide. Consequently, Dextra has been able to provide bespoke solutions to address the modern challenges facing the construction and industrial sectors.

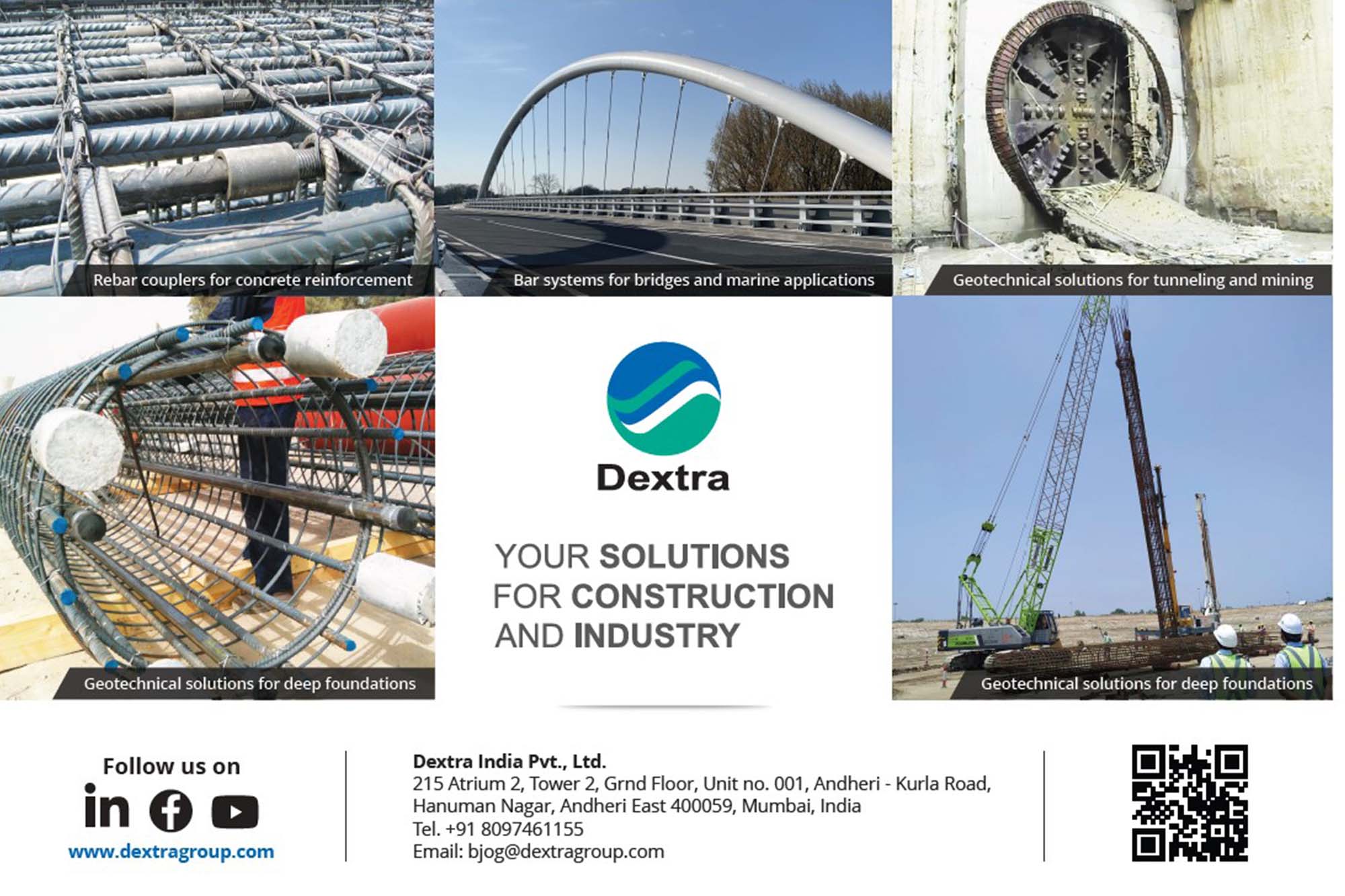

From 3 major industrial sites located in Bangkok (Thailand), Guangzhou (China), and Pune (India), Dextra completely owns its manufacturing facilities and processes. Our product offerings can be broadly categorised into three major segments: concrete reinforcement solutions, high-tensile bars, and ground engineering solutions. Under concrete reinforcement solutions, we offer in situ couplers, precast couplers and speciality repairs and retrofit couplers. Our high-tensile bar range covers marine ports, bridges & PT applications. Our ground engineering solutions include metros, tunnels, and all underground solutions made up of GFRP.

Can you speak about the exclusive range of solutions you offer for high-rise construction?

We manufacture sonic tubes for CSL tests on pile foundations, which are common in high-rise construction. Similarly, the Groutec couplers we manufacture add a lot of technical and commercial value in the case of precast, high-rise construction. These couplers have a threaded connection on one side and a cavity on the other. They are fixed in the precast yard and brought to the construction site. Another product for high-rise construction is the GFRP rebar, an example of a more sustainable glass fibre product and a good substitute for steel rebars. The tension rods we manufacture are used as canopies to add aesthetic value to high-rise buildings.

All these products are more sustainable and environment-friendly, add higher technical value, and are cost-competitive.

How are you contributing to sustainability as such?

Our mechanical coupler reduces the consumption of steel drastically by replacing lapping joints. In numerical terms, the requirement of steel is only 1/10th for couplers.

This directly reduces carbon emissions. Switching from steel to GFRP adds to environment friendliness since GFRP produces 60 to 70 percent less carbon emission. On the same lines, higher-grade high-tensile bars and sonic tubes with just 1 mm thickness also contribute to reduced carbon footprint.

How do you balance cost and functionality?

Using couplers is a cost-effective option compared to lapping because couplers consume much less steel. Similarly, the technical value addition of GFRP should be considered since it is corrosion-resistant, unlike normal steel. When we consider the overall lifecycle of the project – there are advantages like ease of handling, no maintenance, improving project productivity, etc., which directly has an impact of costing.

For more details, visit: https://www.dextragroup.com/

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.