Chenani-Nashri Tunnel: 10 Things to Know About New Lifeline of J&K

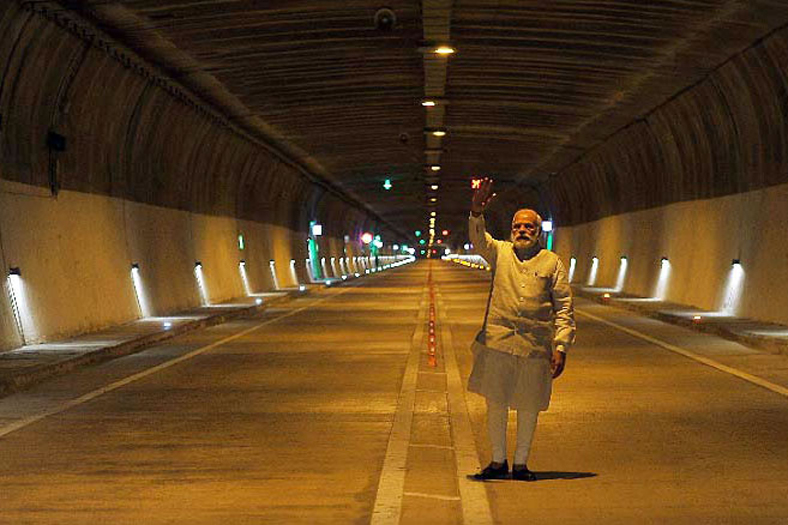

India’s longest highway tunnel at Chenani-Nashri, between Udhampur and Ramban in Jammu & Kashmir has been inaugurated by Prime Minister Narendra Modi on April 2. Here are 10 other key facts that you need to know about India’s longest highway tunnel.

This tunnel will be discussed not only in India, but I believe that the world’s environmentalists who are concerned about climate change, global warming and discuss it, the construction of this tunnel is a big news for them, a big new hope.

– PM Narendra Modi

1Length matters

The 9-km long, twin-tube tunnel between Udhampur and Ramban in Jammu & Kashmir is not only India’s longest highways tunnel but also Asia’s longest bi-directional highways tunnel.

_______________________________________________________________________________________________________________

2To cut travel time by two hours

Built at an elevation of 1,200 metres on one of the most difficult Himalayan terrains, the tunnel will cut the travel time between Jammu and Srinagar by two hours, bypassing about 41 kms of road length.

_______________________________________________________________________________________________________________

3An all-weather tunnel

The tunnel will also ensure an all weather passage on a route that often sees heavy traffic jams and disruptions due to landslides, snow, sharp curves, breakdown of vehicles and accidents.

_______________________________________________________________________________________________________________

4Built with 3,720 Cr

The tunnel was constructed at a cost of about Rs 3,720 crore. It is a part of the 286-km-long four-laning of the Jammu-Srinagar National Highway.

_______________________________________________________________________________________________________________

5Emergency evacuation made easy

The structure consists of a 9-km long, two-laned main tunnel with a parallel escape tunnel of same length. The two tunnels are connected by 29 cross passages at regular intervals along the entire length of the tunnel. These cross passages can be used for evacuation of vehicles and commuters in case of breakdown or any other emergency. There are two minor bridges on the south and north sides and 4-lane approach roads with Toll Plazas on both ends of the tunnel.

_______________________________________________________________________________________________________________

6Special sensors for height checking

The maximum height permitted in the tunnel is 5 metres and for checking the height special sensors have been installed just before the toll points at both ends.

_______________________________________________________________________________________________________________

7Efficient ventilation system

The tunnel has an efficient, transverse ventilation system. There are inlets bringing fresh air at 8 metre intervals and outlet for exhaust every 100 metres. There is also a fully-integrated control system with ventilation, communication, power supply, incident detection, SOS call box and fire fighting.

_______________________________________________________________________________________________________________

8Intelligent traffic mechanism

Fitted with intelligent traffic mechanism, the tunnel has fully automatic smart control and no human intervention will be required for its operations. The tunnel is also equipped with advanced scanners to ward off any security threat. Very few tunnels in the world have this kind of fully integrated tunnel control.

_______________________________________________________________________________________________________________

9Environment friendly

The project is also environment friendly. The time saving on the Jammu- Srinagar route will further result in fuel saving of approximately Rs 27 lakhs per day. Besides, the construction of the tunnel has avoided large-scale deforestation.

_______________________________________________________________________________________________________________

10 Creating jobs

The Chenani-Nashri tunnel will have a very positive impact on the state economy. In line with the Skill India initiative of Prime Minister Narendra Modi, the skill sets of local people were developed and improved, and they were engaged for construction of this tunnel. The project has provided employment to over 2,000 unskilled and skilled youth of Jammu and Kashmir as 94 per cent of the work force was from the state. Around 600 to 900 people from across the country also worked on this project in 3 shifts over the past 4 years.

_______________________________________________________________________________________________________________

ABB’s technology ventilates Chenani-Nashri tunnel

Chenani-Nashri tunnel is the India’s first and the world’s sixth road tunnel with a transverse ventilation system enabled by ABB drives and controlled by ABB software.

For such long tunnels, ventilation systems are essential to maintain clean air, permissible carbon dioxide levels and expel harmful vehicle emissions. To ensure smooth travel and safety of commuters, ABB has designed, engineered and supplied low harmonics variable speed drive (VSD) system for tunnel ventilation. The VSDs and motors are installed at the North (Nashri) and South (Chenani) portals for air supply and exhaust. These VSDs are also equipped with inbuilt redundancy to ensure minimum downtime.

The new tunnel’s safety controls were developed by ABB in India, for effectively mitigating any fire emergencies.

Sterling & Wilson completes electrification

Sterling and Wilson, a part of the Shapoorji Pallonji Group, has been involved in the design, built, turnkey solutions for electrical 11 kV substation, distribution and ancillary works for the four-lane tunnel, which connects Chenani to Nashri across section of NH-1A.

The company has completed the electrification and cabling for fully-integrated control systems – such as communications, power supply, incident detection, SOS call box and fire-fighting. It has also designed and installed a two-tier illumination system, which will be operational around the clock for 365 days a year, with provision for variable frequency drives for ventilation systems.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.