Porotherm Smart Bricks lead to sustainable building innovations

Wienerberger India’s Porotherm Smart Bricks demonstrate exceptional sustainability by utilising innovative recycled materials and delivering long-lasting performance for environmentally responsible building practices.

Porotherm Smart Bricks, Wienerberger India’s flagship product, displayed remarkable environmental performance in a recent Life Cycle Analysis (LCA) done by LEAD Consultancy and Engineering Services (India) Pvt Ltd.

The LCA used the ‘Cradle to Grave’ approach, following international standards (EN 15804+A2 & ISO 14025 / ISO 21930), and analysed several walling materials’ Global Warming Potential (GWP). The ‘Cradle to Grave’ strategy encompasses a product’s whole life cycle, from raw material extraction to production, transportation, installation, and use, to end-of-life.

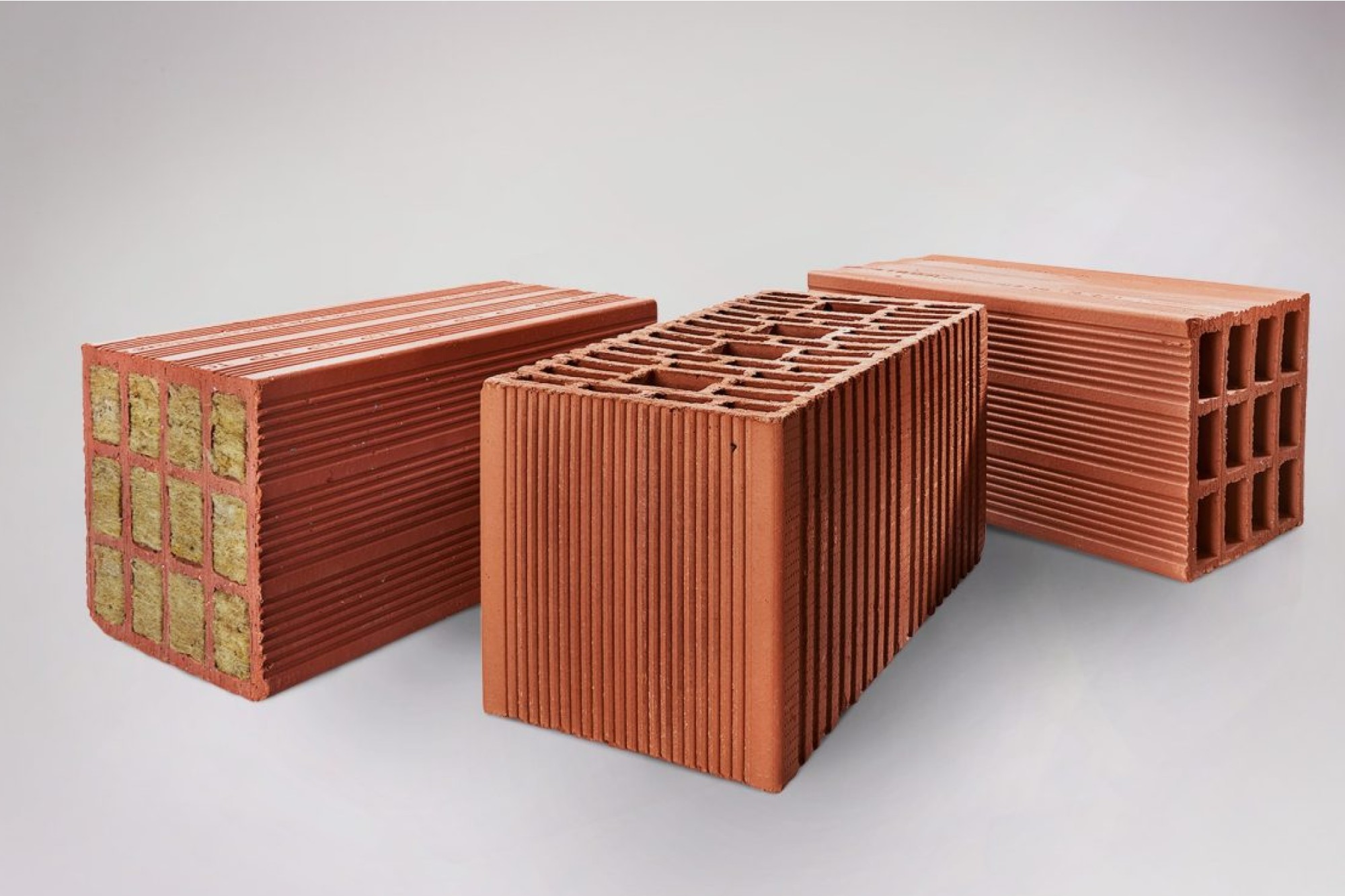

Porotherm Smart Bricks, consisting of Porotherm HP, Porotherm Plus, FB Exteria, and grinded bricks, had an impressive GWP of 97.103 Kg CO2e per tonne, exceeding other materials. Porotherm has a lifespan of 150 years, according to the LCA assessment.

Porotherm demonstrates a significantly lower Global Warming Potential (GWP) compared to other walling materials, as highlighted by a Life Cycle Assessment (LCA). With a GWP of just 97.103 Kg CO₂e/ton, it outperforms alternatives such as Autoclaved Concrete (230 Kg CO₂e/ton), Burnt Clay Bricks (330 Kg CO₂e/ton), Concrete Blocks (400 Kg CO₂e/ton), and Reinforced Concrete Walls (800 Kg CO₂e/ton). For a typical 1500 sq. ft. residence, the total embodied carbon for Porotherm is 1491 Kg CO₂e, considerably lower than Autoclaved Concrete at 3172 Kg CO₂e, Burnt Clay Bricks at 21133 Kg CO₂e, Concrete Blocks at 18401 Kg CO₂e, and Reinforced Concrete Walls at a staggering 52277 Kg CO₂e. This data underscores Porotherm’s environmental advantage in sustainable construction.

“This significant reduction in carbon footprint underscores our commitment to sustainability,” says Monnanda Appaiah, Managing Director, Wernerberger India. “Our eco-conscious approach enables us to create environmentally friendly products, contributing to a greener future.”

Porotherm is made from 90 percent recycled waste materials, including stone slurry, rice husk, and tank clay, which is silt gathered during the de-silting of dead tanks and lakes. Only 10 percent of its basic materials are derived from clay mines. Porotherm’s revolutionary method of using recycled materials not only lowers waste but also greatly reduces the product’s environmental footprint, making it a sustainable choice for construction.

Porotherm’s sustainable manufacturing process possesses advantages that go beyond environmental ones. Using recycled materials reduces waste disposal costs, conserves natural resources, and lowers energy use. These qualities contribute to a more cost-effective and environmentally responsible building method, bolstering Porotherm’s reputation as a sustainable and efficient walling solution.

For more details, visit: https://www.wienerberger.in/

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.