Ready-mix concrete industry is still in infancy

Ready-mix concrete industry is still in infancy

Compared to China or other leading economics, the cement consumption in Indian RMC industry is still in primary stage. An interview with Pravin Lal Thirwani, Head (Sales & Marketing), Godrej & Boyce

Ready-mix concrete (RMC) is a well-studied product, which means all the raw materials and their combinations are investigated thoroughly before any supplies are done. Pravin Lal Thirwani, Head (Sales & Marketing), Godrej & Boyce Mfg. Co. Ltd., speaks about the advantages and challenges faced by RMC sector in India.

Growth of the industryRMC was invented a century ago, though it entered India only in the 70s. The Indian concrete market is about 300 million cubic metres a year, which is huge. The demand for gigantic infrastructure and housing in India calls for even more growth of the RMC industry which is growing at an annual rate of 20 to 25 per cent. The cement consumption in RMC industry is rising, and today it’s gauged approximately at 8 per cent of the total cement produced by the country. However, the RMC business in India is in its infancy. RMC business in the developed countries, consumes nearly 70 to 75 per cent of cement.

Advantages of RMCRMC has several advantages over the conventional method. That’s why the RMC penetration is increasing day by day. Most important, the quality factor: RMC is a well-studied product, which means all the raw materials and their combinations are investigated thoroughly. This takes not only the level of quality assurance higher but also optimizes the raw material content, yielding technical as well as commercial benefits to the customer.

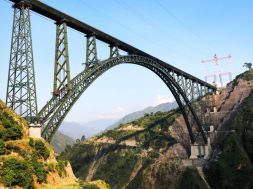

Apart from the quality, the speed of today’s construction could be achieved only through the use of RMC. The high-end mechanised batching plants not only deliver huge volume in less time and save cost, but also give a peace of mind by complying to the timing restrictions of urban residential areas. RMC uses state-of-the-art knowhow and equipment to deliver tailor-made concrete for each project. This way, it makes possible to realize of difficult-to-execute structures, and gives the architects free rein to their artistic imagination.

Mega projects taking shape in Tier 2 citiesWith the changing time, the trend of mega projects is taking shape in Tier 2 cities. Mass housing and infrastructure projects provide the requisite impetus to the industry growth in other cities.

Government’s roleGovernment has a major role to take the advantages of RMC to Tier 2 cities. Major thrust on infrastructure will increase the demand for concrete. The quality and environmental benefits can be imparted to other areas by specifying the use of RMC in major public and construction projects. Enhanced use of green material like fly ash and slag should be adopted in tender specifications to promote the industry.

RMC was not excisable till 2011. Then the excise duty was imposed, giving an in-direct hit on the consumers’ pocket. Government can help the industry grow better in other cities by giving special benefits on duties and taxes.

The technical capacity of the industry should be leveraged by co-working with the industry leaders, for the development and use of special concrete products in typical applications, e.g. high-performance concrete in cement concrete roads.

Pan India expansionGodrej RMC set up its first fully automatic batching plant in Vikhroli in 1999. Since then it bears the unique identity for quality and service in Mumbai and Pune region. Keeping the huge concrete demand in mind, Godrej RMC is planning to take its concrete solutions to other cities, starting with western India and then moving to other markets.

The biggest challengeRMC is transported through the transit mixers from plant to the site. Heavy traffic jams are the biggest challenges for transportation as the shelf life of RMC is not more than 3 to 5 hours. The other major problem is the congestion which makes it difficult for manoeuvring the transit mixers at desired point. Time restriction for heavy traffic in most of the roads is increasing day by day, making the transportation problems worst as well as hampering the quality and productivity of site execution.

Special sanction for transportationThe challenges for transportation of live products like RMC can be overcome by authorities’ intervention. Either allowing RMC transportation through specific routes or permitting critical projects to carry the construction activities during the night can be the resolution to face such problems. The other way to tackle the issue is to co-work with the customers in terms of their demands and time restrictions, and to schedule the dispatches as per the feasible timing of site execution and route-entry restriction. However, this is not practically applicable for mass concrete pours, this s good only for small pour sizes.

If the project size is huge in volumes, the better solution would be setting up RMC plant on-site of the project or near to it. This, in fact, is a growing trend as the project sizes are increasing day by day.

RMC equipment available through MNCs Today world-class equipment are available in India too—either through the MNCs’ own offices, or their local representatives. Exhibitions like bC India also give an opportunity to the people at project level to see these equipment in person which was, otherwise, restricted to senior management in international exhibitions.

The demand for high-performance concrete is increasing day by day in metros, making it inevitable for the RMC plant makers to innovate better techniques like automatic multiple additives loading systems, chilling plant or facility involving addition of ice-flakes in concrete.

The systems and software have been upgraded to maintain monitoring and reporting online. Information on development in new types of concrete and new raw materials for concrete are easily available through Internet. Frequently held international seminars also give a chance to the engineers to interact with international experts on different subjects. These forums are becoming the real-time advantage in the construction industry.

Initially, the plant availability was restricted to the maximum capacity of 30 cubic metres which has grown to 360 cubic metres today. A number of plant manufacturing companies, which were earlier reluctant, have entered in India because of high-infrastructure growth in the last 7 to 8 years. This has also opened doors for many Indian players to foray into the market. Due to increasing demand of pollution control and fast, easy plant erection, tower and container plants are also available in India.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.