Self-healing concrete is set to transform global infrastructure

Dr. Conor O’Brien, Senior Technology Analyst of IDTechEx, examines how self-healing concrete technology can improve infrastructure longevity and reduce global repair costs.

Material corrosion and degradation problems cost developed countries about 3 percent of their GDP annually. Damage to concrete structures and infrastructure, ranging from minor cracks to complete failure, can cause major disruptions and require significant repair costs. What if damaged concrete had the ability to self-heal microcracks before they grew into larger-scale problems?

The IDTechEx report “Self-Healing Materials 2025-2035: Technologies, Applications, and Players” provides a detailed overview of the market, including insights into technical challenges and progress, key sectors for market growth, and commercial readiness levels. A third-party, independent market assessment is provided throughout, including an unbiased outlook for the covered materials and industry sectors.

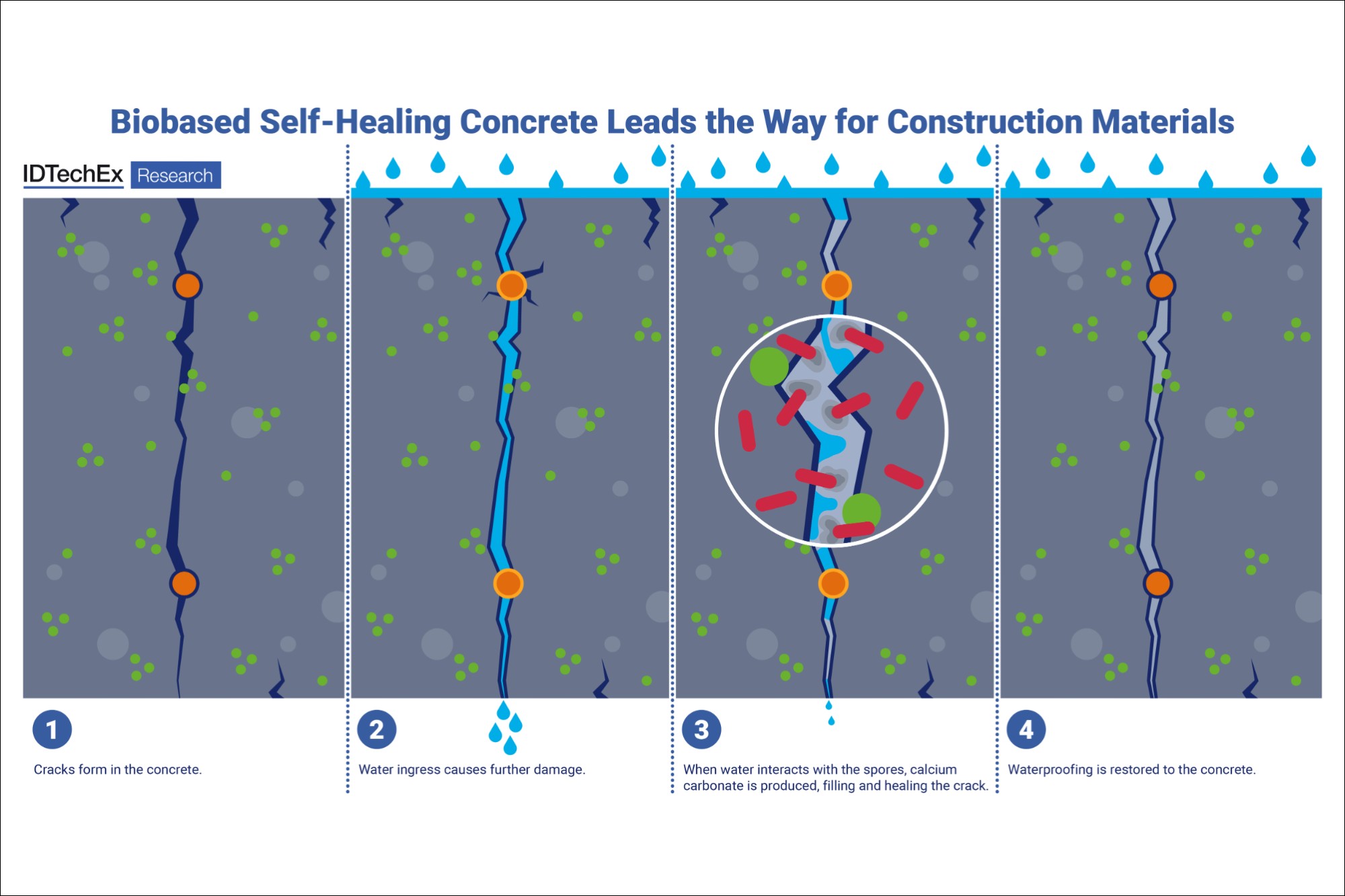

Concrete typically fails due to the formation of microcracks, which eventually grow into larger cracks. Freeze-thaw action can be a major problem, as water fills cracks before freezing and expanding, causing additional damage in a repeating cycle. Self-healing concrete is intended to repair these microcracks efficiently. Many technologies exist, but IDTechEx research indicates that biological approaches will pave the way for the successful commercialisation of self-healing concrete.

An ancient approach

In spite of the fact that Rome was not created overnight, many of its most exquisite buildings and structures have endured for more than two millennia. Roman concrete is made of quicklime (calcium oxide), volcanic ash, and water and was created at high temperatures using a technique known as “hot mixing”. According to studies, lime clasts (calcium-rich mineral deposits) can be seen in Roman architecture as small, distinct white features measuring a few millimetres in size.

When a crack forms, water infiltrates and produces a calcium-rich solution. Despite extensive research, two potential healing mechanisms exist. In the simplest case, the solution heals the crack itself. The second and more complicated mechanism is known as the pozzolanic reaction, which involves the formation of several intermediates at the interface of the volcanic aggregate and the surrounding matrix.

Modern methods

A promising approach from players like Basilisk involves embedding mineral-producing bacteria into concrete to promote self-healing. These acid-producing bacteria can be dormant for more than 200 years, acting as catalysts in the crack-repair process. When cracks form, the bacteria become active, consuming calcium lactate and producing limestone to seal the damage. Bacillus pasteurii, B. sphaericus, B. subtilis, B. cohnii, B. halodurans, and B. pseudofirmus are some of the bacterial strains used in construction.

The healing process involves a biological reaction between unreacted limestone and a calcium-based nutrient. When bacterial spores come into contact with water, they begin to feed on calcium lactate, which consumes oxygen and reduces the risk of steel corrosion. The soluble calcium lactate is converted into insoluble limestone, which hardens and seals the crack.

The IDTechEx report also discusses different approaches to self-healing construction materials. Geopolymer concrete is made from waste materials like fly ash, and self-healing mechanisms have been proposed. There is also a compelling method that uses bacteria-coated fibres. The main advantage is that the core of the fibre acts as a stitch, keeping the crack closed and limiting the amount of self-healing required.

Concrete provides a high-volume route to market for self-healing materials, fostering confidence and trust in the novel approach to extending structure lifespan. Initial risks can be reduced by only considering slabs, with vertical pours for walls postponed until phase two of adoption. According to IDTechEx’s market assessment, adding self-healing properties increases material costs by 30 percent; however, this can be accounted for in a variety of ways. Saving on the aforementioned GDP loss, reduced need for replacements, reduced maintenance, and limited downtime can all be summed up in the overall life-cycle costs that are reduced when considering self-healing concrete.

The “Self-Healing Materials 2025-2035: Technologies, Applications, and Players” report offers a thorough examination of this emerging market. Using its expertise in advanced materials, IDTechEx provides an independent evaluation that includes technology comparisons, industry trends, and key player assessments, providing valuable insights into this promising but still-developing sector.

For more details, visit: http://www.IDTechEx.com.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.