18 Terex tower cranes for Copenhagen Metro

18 Terex tower cranes for Copenhagen Metro

When Terex helped in the construction of largest ever archaeological excavation in Denmark

Eighteen Terex CTT flat-top tower cranes are helping at the 4th and final phase of the Copenhagen Metro — the €1.7 billion Cityringen or City Circle Line — one of the biggest construction projects in Denmark. The new 16-km underground line will feature a total of 17 stations: 12 newly built, three conversions of existing stations and two existing. The line will carry about 275,000 passengers each day. Initially, the flat top tower cranes will be used to remove excavated tunnel material, then to lift in new concrete and materials for the new construction.

The Copenhagen Metro was the 1st fully automated, driverless metro. It opened in 2002 with trains running at speeds of up to 80 km per hour, 18 metres below street level. Six years later, the Metro won “The World’s Best Metro” title by a global jury of transport specialists impressed by its high level of stability, security and 98 per cent punctuality of all trains. Because of its success, it was decided in 2005 to expand it further to include the new City Circle Line.

Work on the new line started in 2012 and, when finally completed in 2018, will increase the number of Metro stations to 37 and tie together Copenhagen’s different neighbourhoods. A round trip on the new City Circle Line will take about 24 minutes. 85 per cent of all homes, places of work and educational institutions in the inner city and its surrounding neighbourhoods will be less than a 10-minute walk from a metro or train station. The two new lines of the City Circle Line – the M3 and M4 – form a giant ring across the present M1 and M2 metro lines allowing passengers to transfer between the new and the old metro lines at the Kongens Nytorv and Frederiksberg stations. New metro stations will be built at busy hubs such as Copenhagen’s Central Station, Rådhuspladsen, Nørrebro Runddel and Trianglen in Østerbro.

When work is completed in about 4 years, it will make moving around the city much easier, faster and more convenient.

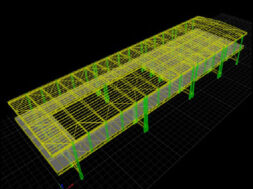

The project is being built by a consortium of companies – the Copenhagen Metro Team (CMT) – with individual companies having the lead on different aspects such as safety, drilling, material processing, track laying and construction. CMT purchased 18 tower cranes – all Terex CTT 231 models with maximum lift capacities of up to 12 tonnes and with different under hook heights and jib lengths – because of their combination of good lift capacity with precise and easy control of movements. CMT purchased the cranes as part of the ‘Full Terex Package’ which includes expert advice on configuration, its positioning, erection, maintenance, training and support. This support is ongoing throughout the project and adjusts for the changing demands and client requirements for the equipment in future projects.

One example of this support was to comply with a local Danish regulation that required all cranes over 25 metres to have an elevator for the operator to reach the cab. Terex cranes liaised with a Swedish elevator supplier in nearby Malmö and not only solved the problem with a turnkey solution but also trained the maintenance company’s engineers to support the crane. Terex also helped with the logistics involved in delivering the cranes into the busy city centre, including the completion of calculations for special travelling rail-mounted bases and tracks needed for some of the cranes, a detailed plan to erect the cranes and guidance on short jib applications.

“The Terex tower cranes, expert advice and support have all been excellent,” said Eliseo Marsiglio, Project Manager, CMT. “This is a complex contract made more difficult because of the situation in the centre of Copenhagen. These CTT tower cranes are designed for working on confined sites and have very good lift capacities – it is early days but at the moment we are very pleased with the investment.”

Ivo Romanelli, Service Manager, Terex Cranes, said, “The tight construction schedule and the situation in the middle of the city pose big challenges to providing service and support. But we have had very positive feedback from the client CMT.”

Initially, it was thought that half of the CTT 231 tower cranes will have a traditional concrete base while the others will have a travelling rail-mounted chassis. However, due to the continual changes in the configuration of some of the sites and geological variations, just one crane has so far been erected on a travelling chassis with 30 metres of rails. A further five cranes are scheduled to be erected on rails but this will depend on various factors.

“The cranes have to perform two different activities – first lifting tunnel spoil from the pit and then moving the construction materials,” said Romanelli. “We are continually advising the client on the best set-up of each crane including jib length and whether to have a travelling chassis or normal foundation after talking with the site manager for each station.”

The initial phases of construction have also resulted in the largest ever archaeological excavation in Denmark providing archaeologists with the opportunity to further map out Copenhagen’s history. One discovery already made is of an 8th century harbour which means that the city is about 300 years older than previously thought.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.