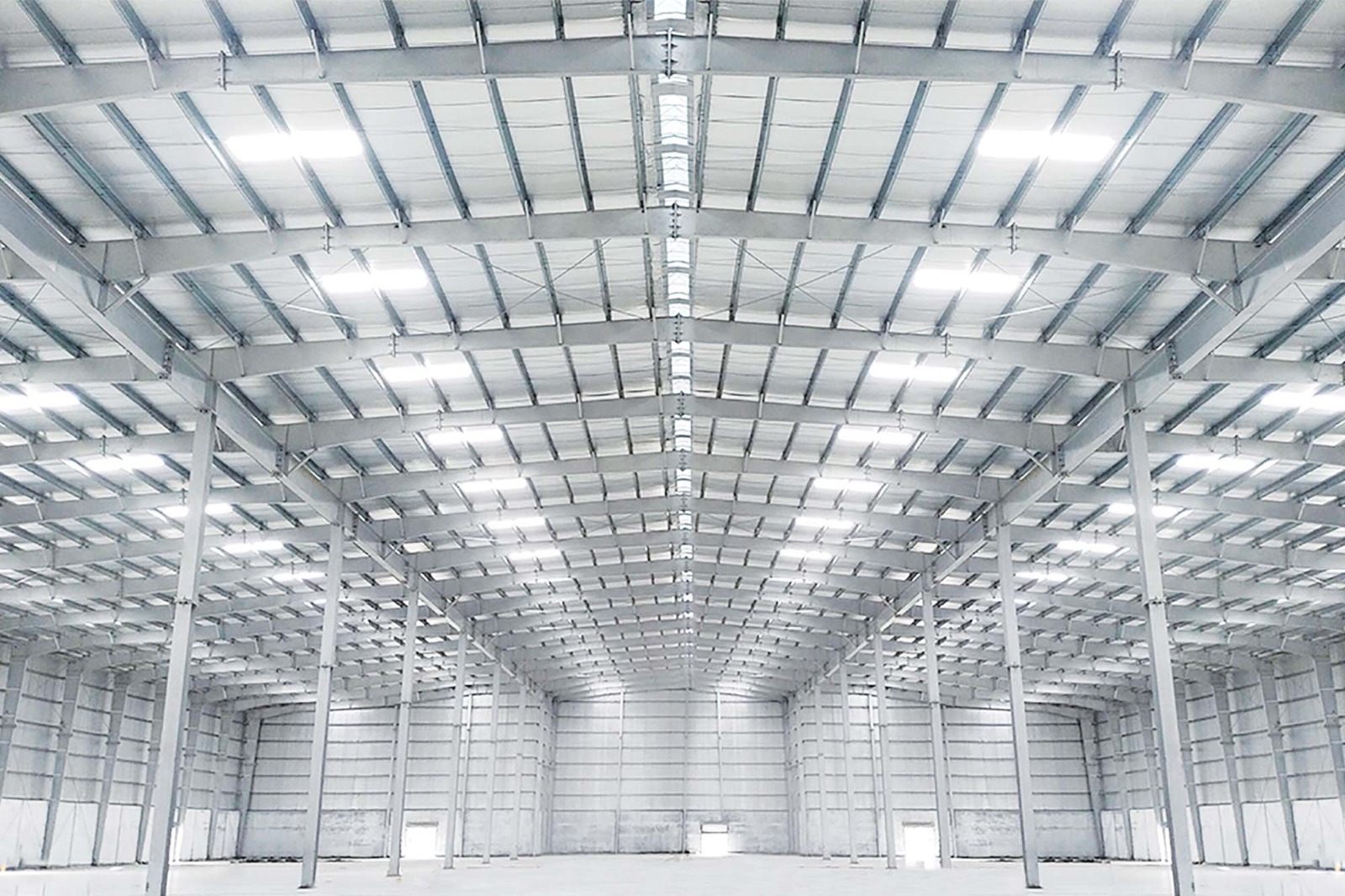

Optimised structural designs for sustainable construction

This exclusive interaction explores Bajaj Steel’s range of solutions, recent advancements, technological integration and sustainable practices.

What sets your company’s steel structures apart from others regarding design flexibility, durability, and cost-effectiveness?

Bajaj Steel Industries is a BSE-listed organisation. The infrastructure division was set up in 2010. We have executed more than a thousand projects catering to diverse customers, such as warehousing, industrial sheds, sports complexes, high-rise buildings, schools and offices, special client requirements for pharmaceuticals, food and beverages, cold storages, and epc projects with renowned organisations like Indian Oil Corporation, Nuclear Fuel Complex, Maharashtra State Warehousing Committee, and many more.

All our products are designed and detailed using high-end software like MBS 2021 and TEKLA, which gives us an edge in structure optimisation. Using prime mill-grade material of optimum sizes based on designs ensures that our structures are stable, solid, and durable. We use the best mill-grade material on the latest CNC-controlled manufacturing setup. We believe in providing quality materials and products to ensure long-term cost benefits to our clients.

How do you ensure structural integrity and safety, particularly in challenging environments or extreme weather conditions?

The design for each structure is carried out using the latest software, such as MBS 2021. While the data library for structure design is very exhaustive, our design team of considerable experience ensures that every design is optimised. Every parameter like wind load, seismic load, and loads within the shed like solar, fire fighting system, cranes, mezzanines, false ceilings, office working and much more are duly imbibed and the structure design. Apart from this, environmental and working factors are also duly considered, and suitable resolutions by way of paint, treatment of structure like hot dip galvanising, and use of suitable grades of cladding are suggested.

Can you discuss any recent advancements or innovations in steel fabrication techniques or materials that your company has incorporated into its products?

On our part, we have introduced, in India, a PET-coated cladding using Nano Technology that gives substantially enhanced life even in the corrosive working environments of alkaline and acidic nature and a wide range of working temperatures from -20 deg Centigrade to 120 deg Centigrade. This material has a unique embossed pattern on the surface, which helps the product cushion noise, and the Ultra-High reflective outer surface reflects heat and ensures cooler interiors by up to 8-10 degrees Centigrade.

In what ways does your company support sustainable construction practices through its steel structure solutions, such as utilising recycled materials or optimising energy efficiency?

We do not use recycled material during any stage of manufacturing. Recycled material compromises the structural strength and integrity of the structure. Bajaj Steel ensures reduction in wastage across all its facilities by optimum utilisation of material, resources, and non-renewable resources, usage of saving energy devices on machines, motors, and equipment, and use of renewable energy sources to reduce our carbon footprint. Renewable energy sources power all utilities, lighting, and many small machines.

For more details, visit : https://bajajngp.com/

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.