High-performance concrete is here

This exclusive interaction highlights the first commercial Ready-Mix Concrete (RMC) plant for ACC, the introduction of innovative pavement solutions, and how Dhuri’s contributions have been instrumental in transforming the nation’s infrastructure landscape.

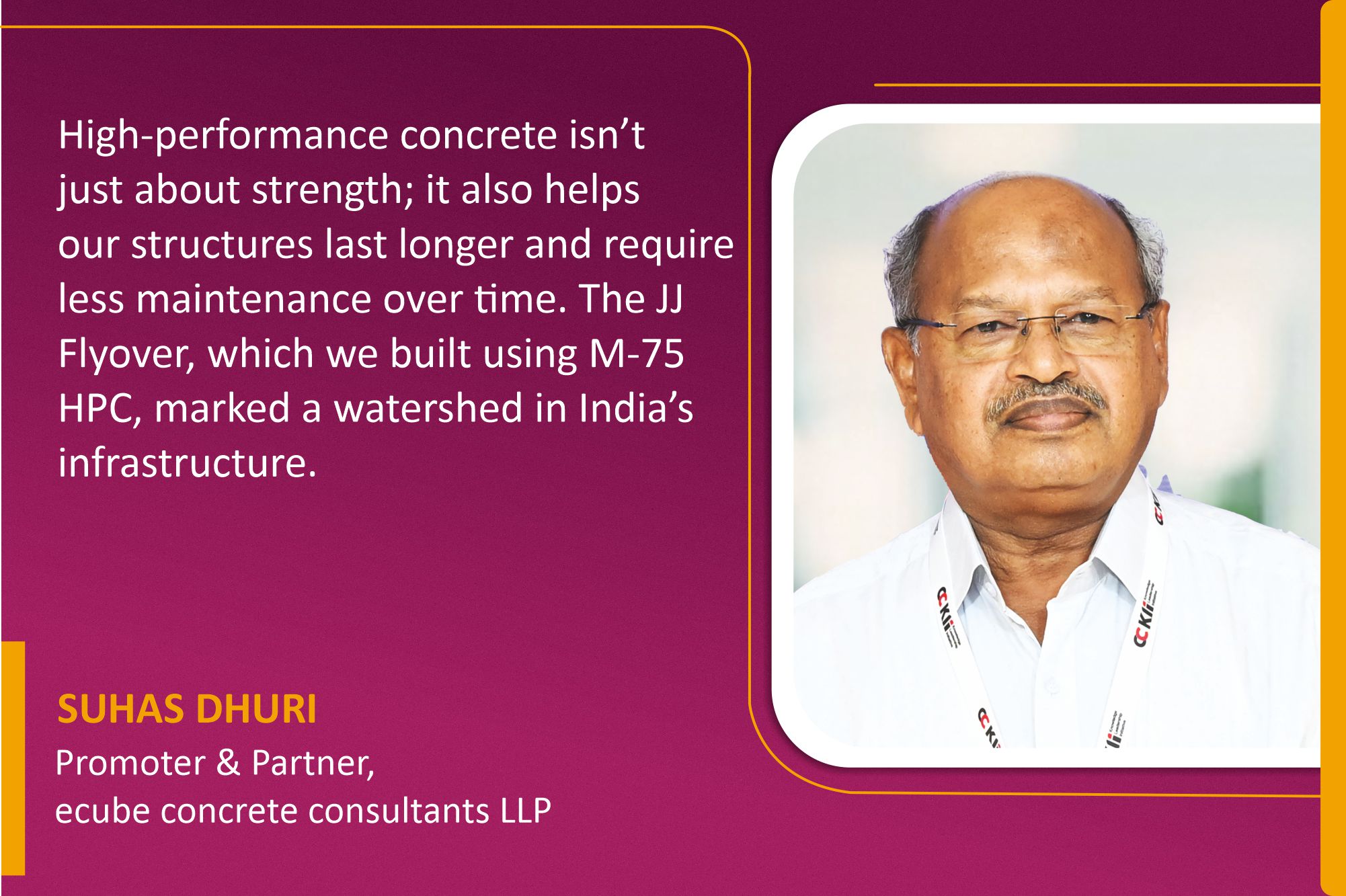

What challenges did you face in introducing high-performance concrete (HPC) in India, particularly with the JJ Flyover Project, and how did you overcome them?

In 1980, I started as a civil engineer in ACC’s R&D division, focussing on concrete development. Over my 45-year career in the concrete industry, a key milestone was developing M-75 grade concrete for the JJ Flyover in 1998, which was pioneering at the time. 2005, I founded my consultancy to address the growing need for expertise in managing concrete projects across India. High-performance concrete is critical for increasing the longevity of construction. Structural concerns sometimes necessitate recurrent repairs; however, using high-performance concrete reduces the requirement for frequent repairs, extending the structure’s life.

MSRDC recognised that high-performance concrete, specifically M-75 grade, could produce better outcomes than conventional concrete, which was unique at the time. They introduced various international tests for this specific concrete, and we conducted intensive instrumentation and testing, which took around six months to develop. At the time, the supply of high-quality admixtures was limited. Chemical admixtures have evolved greatly with the introduction of third and fourth-generation polycarboxylate (PC) admixtures. We were experimenting solely with sulfonated naphthalene formaldehyde (SNF) admixtures.

What pivotal moments shaped the success of establishing the first commercial Ready-Mix Concrete (RMC) plant for ACC at BKC, Mumbai?

The contractor brought their own RMC facility, but we persuaded Bharat Diamond Bourse that concrete is a specialised substance requiring expertise in its management. Given our vast R&D experience, we thoroughly understood the raw ingredients and their impacts on concrete. As a result, Bharat Diamond Bourse chose to split the concrete supply from the primary contractor and committed it to us. We produced high-performance and long-lasting concrete for the Bharat Diamond project in 1993.

Could you explain the concept of Ultra-Thin White Topping and its advantages over traditional pavement solutions?

Traditional pavements typically employ M40 grade concrete, as stipulated by CBRI, with a thickness of approximately 300 mm. However, employing hybrid concrete, such as M60, decreases the pavement thickness to 50-75 mm. This considerable benefit enables the repair of existing roads while reducing the risk of cracks. Our first assignment using this approach was in Thane in 2006, and the road has performed admirably since then, with no potholes. This highlights the fundamental advantages of ultra-thin, white toppings.

How have you managed temperature gradients to prevent thermal cracking in large-scale concrete pours?

Creating a concrete mix design is the first stage. The production of Ordinary Portland Cement (OPC) produces great heat. To counteract this, more cementitious materials and less OPC should be added, which can help lower heat while preserving the necessary strength. Using the ice concrete mix and modifying the other parameters appropriately is an additional method. The first stage is to make your concrete mix with many extra cementitious materials and high-performance admixtures.

How do diverse types of admixtures influence the rheological properties of concrete? Could you discuss their impact on workability, pumpability, and finishing characteristics?

Admixtures interact with cement particles by charging and repelling one another, improving workability while maintaining the same water content. However, adding viscosity-modifying chemicals drastically alters the concrete’s rheological properties. In some situations, these innovative admixtures may eliminate the requirement for additional energy to consolidate the concrete, emphasising its unique capacity to produce self-compacting concrete.

For more details, visit: https://ecubemumbai.com/

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.