The Ludhiana Beverages project

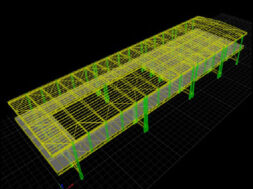

Kirby was involved in design, drafting, fabrication, supply, and construction of Pre-Engineered Steel Building for Ludhiana Beverages, an authorized bottler of the Coca-Cola company which is involved in manufacturing of Coca-Cola products

Ludhiana Beverages is the authorized bottler of the Coca-Cola company and is involved in manufacturing of Coca-Cola products. The client floated the tender for their upcoming greenfield facility where Kirby India bagged the Pre-Engineered Steel Building (PEB) requirement with tough competition from various other PEB players. Kirby is proud to

get associated with the prestigious client – Ludhiana Beverages for their upcoming manufacturing facility. Kirby has already executed many facilities for beverage manufacturing companies across India and this project is one of the flagship projects in the company’s history.

The complete structure is built of steel which is more than 80% recyclable. All the raw material such as plates and coils are procured from India’s top steel mills as per the customer’s specifications thereby supporting government’s VOCAL FOR LOCAL initiative and then processed as per the shop floor drawings with different dimensions and modularities with strict control on accuracy.

All the raw material procured from the steel mill undergoes quality testing as per our standard’s and is then released for fabrication by the Quality Laboratory. After the fabrication as per the shop floor drawings approved by the customer, finished product once again undergoes inspection and quality check for final dispatch to the jobsite.

Client Name: Ludhiana Beverages Pvt Ltd

Steel Solution Provider – Kirby Building Systems &

Structures India Pvt Ltd (Kirby India)

Design Consultant, Architects & Engineers – Munish &

Associates

Tonnage – Approx. 2,500 MT

Area – 43,500 square meters

Jobsite – Hoshiarpur, Punjab

Building Usage – Factory Building

Industry – Food & Beverages

Overall role in the project

Kirby was involved in design, drafting, fabrication, supply, and construction of Pre-Engineered Steel Building. Kirby used its highly customized SAP system implemented in 2008 for

complete project tracking and monitoring right from enquiry stage to dispatch to final invoice. The entire project was smoothly handled with proactive steps in timely escalation and

resolution of any issues, material tracking, deployment of labour at site, etc. All these enabled us to complete the project as per the schedule committed to the customer with highest safety and excellent workmanship thereby leading to zero accidents at site. Kirby adhered to all the safety standards such as safety gear usage, display of posters, toolbox training, training on working at heights, motivational programs, etc. which is followed regularly across the project locations.

Erection Techniques

Three numbers of 50 MT crane were used for erection of all the buildings. The buildings were installed using Kirby’s standard erection procedure as the final look and feel of the building depends to a great extent on the quality of the installation at site. The erection process was highly technical and required skilled and trained manpower to effectively execute the works and handle heavy construction equipments. Erection was carried out under the company’s supervision with world class safety standards. Regular training sessions were conducted at the site to educate the builder staff and workmen on correct installation procedures and Environment Health & Safety (EHS) practices to be followed on day to day basis.

Major Challenges faced during Erection

Major challenge faced during the erection of the project was installation of roof sheeting during the monsoon period. The site was filled up with water and the project had to be handed over to the client as per the schedule without any delay. Because of heavy rains, KSS mill was installed on temporary platform built on the existing foundations and the sheet was roll formed and installed by deploying double manpower.

For more information, visit:

www.kirbyinternational.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.