Trimble fostering BIM-led construction

With Trimble solutions, customers around the world are finding out how smarter buildings can be built by using smarter tools.

India is at the cusp of a growth tangent, economic reforms are taking hold and initiatives like smart cities will drive urbanisation to the next level. The continued urbanisation is a very critical challenge and an opportunity for all the business and stakeholders and technology companies like Trimble would like to be part of the transformation in the ‘built’ environment in India.

Technology has a very important role to play in improving productivity, driving cost efficiencies, reducing wastage and rework, and these points are on top of the list for various stakeholders engaged in a construction project’s lifecycle.

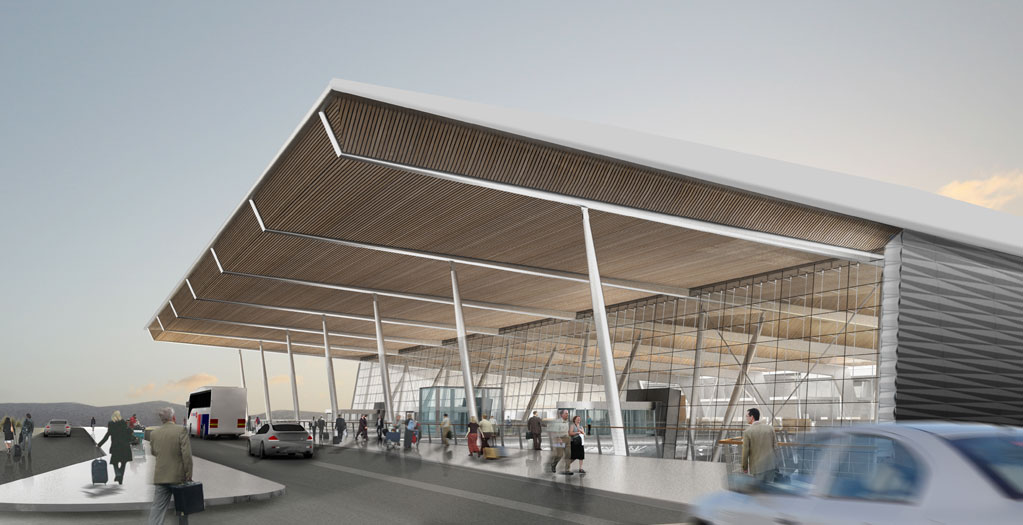

Let’s take the example of smart cities. Amongst other elements that define a smart city, an important element is construction of smart buildings. According to Jayant Keswani, Director, Marketing, Trimble Solutions India Pvt Ltd, “A smart building enables ideal, efficient and smarter optimisation of space. This is possible through smarter design, smarter construction, smarter co-ordination, smarter planning and smarter operations. This is where IT solutions and organisations like Trimble step in.”

With the passage of time, construction industry has passed through much advancement. One of them is emphasis on designing buildings before actually constructing those buildings, said Keswani. Trimble refers to this 3D model as a ‘constructable model’ and it is very beneficial for developers and contractors as it helps to give them a world class finished product and overcome any obstacles that may come up before they actually ‘build’ the structure. Computer aided designing helps in designing flawless buildings, and through computer simulations, problems can be found and resolved before constructing buildings physically. This process is commonly referred to as Building Information Modelling (BIM).

BIM is a technology process that facilitates collecting information about buildings under construction on a regular basis. It enhances the communication among engineers and designers that are working on the project and enables smarter construction. Globally it has been established that BIM software permits different players in the construction chain from architects to engineers, building contractors and even asset owners to work collaboratively and more productively. BIM is an important facilitator of savings for the construction sector. A majority of savings can be achieved by tighter information flow with project designs agreeing with each other, by the time essential tasks are commenced. BIM implementation ensures that documentation is coordinated, timely and is available in an accessible form with agreement on information deliverables, which in turn ensures that projects are progressing as planned.

Keswani observes, “In most western markets and some Asian countries like Singapore, using BIM is almost mandatory for the construction industry. While the value of BIM helping the whole workflow has been better recognised in mature markets, in India we aren’t quite there yet. While BIM has been a buzzword for a while now, many of the projects are still 2D based. But at the same time, complexity of construction industry is also growing and this will compel most contractors and engineers to adopt BIM soon. BIM results in the strands of information agreeing with each other, clashes being identified upfront, thus reducing rework, conflicts, waste, delays and thereby allowing opportunity for innovation and increased budget certainty. No contractor or engineer can afford to ignore these benefits and Indian construction landscape will see much quicker adoption of BIM.”

Trimble is uniquely positioned to ensure smarter construction with its portfolio of solutions and services. Trimble acquired Google’s Sketch Up business in the design space a few years ago and has a professional version for designers and architects. Trimble’s design and engineering technology services offer solutions for concrete and steel construction. “We also provide estimates, project and facilities management to cover the entire lifecycle of construction activities. Thus, we have established our prowess in the design, build and operate space fully and our technologies help manage more than 2 million sq.ft. space in real estate. With our 3D solutions, we are capable to manage and optimise the entire lifecycle cost of the buildings the world works upon, and provide the best service to our customers,” informs Keswani.

Creating breakthrough

Revealing about the breakthrough technology of 2016 Toni Kamula, Global Marketing Manager, Concrete Segment, Trimble Solutions Corporation says, “In 2016 there were several new technologies introduced for Tekla software to support more efficient concrete workflows and to help precast and CIP concrete industries to improve productivity and work in a more cost efficient way utilising constructible concrete models. Trimble’s Tekla software offer specialised solutions for different type of user groups, for structural engineers, for precast, rebar and steel detailers and fabricators and to concrete contractors planning and pouring concrete on site. Different user groups have different needs when it comes to BIM, so it is quite difficult to mention just one technology.”

One example is next generation concrete wall and floor modelling and detailing tools introduced by Trimble in 2016 to support more efficient design and detailing workflows in residential building projects. The new functionalities introduced were the most used concrete tools in Tekla Structures in 2016. Effective transfer of information between detailing department and precast plants were also improved with the new data exchange formats developed together with the precast production automation system developer Unitechnik.

Kamula adds, “Last year we also introduced several new technologies to support more productive CIP concrete onsite workflows. New functionalities introduced for Tekla Structures continue to improve quick and easy pour information management with the constructible concrete model supporting more efficient pour planning and more productive concrete pour work on site.”

In 2016 the company also made a great leap forward with its offering for concrete formwork planning with Tekla Structures. “Formwork is one of the most time-consuming parts of cast-in-place concrete construction, which makes good planning essential. With the new offering and the enhanced visualisation, coordination and communication made possible by the constructible formwork models, contractors can speed up the formwork planning and save time, prevent mistakes and streamline the formwork operations on site,” he notes.

New technologies benefit the whole concrete construction, enabling more productive and error free way for concrete industry to work, but can be considered to be a bit type, which are targeted to improve certain user group’s workflows, like precast detailers and fabricators and CIP concrete contractors. “If we want to mention only one technology supporting whole construction industry, it has to be a Tekla Model Sharing technology which was introduced already in 2015 but really made progress in the use by our customers in 2016,” states Kamula.

Tekla Model Sharing, enabling easier collaboration

Tekla Model sharing allows Tekla Structures project teams to work efficiently together, locally and globally, regardless of their location or time zone. Using Tekla Model Sharing, teams can collaborate effectively on the same Tekla Structures project. The solution adapts to any Internet connection speed, and you can also edit the models offline. Tekla Model Sharing enables completely new ways for project teams to work by making it possible to the company’s customers to flexibly manage teams even if they are working in different time zones. One team can work in the US and another one in India using the same Tekla Structures model. The service allows the company’s customers to balance the workload across teams and offices according to their resources and enables easily to bring together the right people for the successful project.

Sharing his views on how this technology is adding value to the business, Kamula says, “With Tekla Model Sharing we can offer an improved and more flexible way for our customers to work in their projects using Tekla software. It benefits the users of Tekla Structures in their local workflows and enables them to work in a completely new, more efficient way with the other, regional or global project teams using Tekla Structures. Tekla Model Sharing greatly improves our overall offering adding value for our main product Tekla Structures and enables us to better differentiate and add value against our competitors.”

A successful case study

UPB Holding,a major in industrial enterprise groups in Latvia, uses Tekla Structures through the whole process, from estimation and sales to design and detail to fabrication of different products. They utilise accurate information in constructible models in every stage of their processes. “Use of Tekla Model Sharing has brought a new type of flexibility in collaboration and communication into the way they work,” Kamula adds.

Sharing the experience of using Tekla Model Sharing in their projects, Arturs Neiburgs, the Head of R&D, Engineering Department at UPB said, “Shorter design time has been the most obvious benefit of using Tekla. We can also bring in as many designers as needed to speed up designing process, even if the designers are in different offices or countries. We are now more flexible. Secondly, we can deal with much more information that gives us many more possibilities.”

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.