Groutec is a mechanical splicing system with one threaded end designed for the connection of precast concrete elements. Groutec splice complies with Eurocode 2, BS8110, ISO 15835, ACI 318 type 2 and AASHTO code requirements. Metric ribbed reinforcing bars of grades up to 600 MPa and ASTM deformed reinforcing bars of grades up to 80 ksi can be spliced with Groutec.

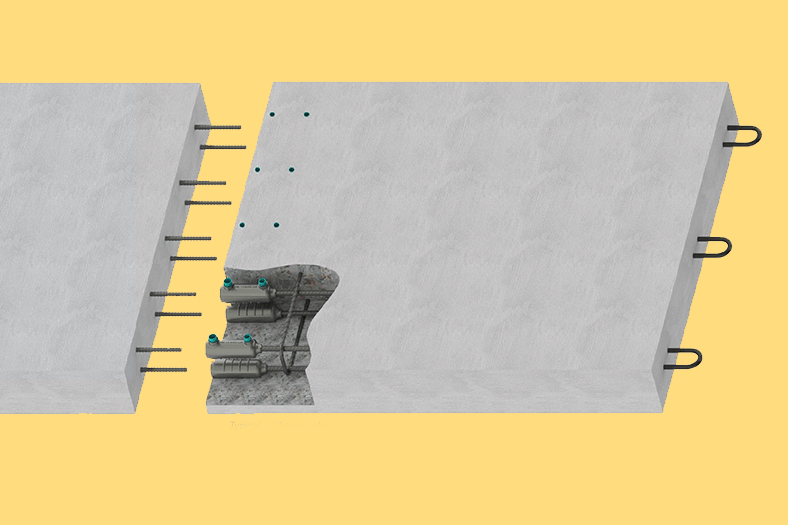

Splicing is usually done in two steps: the Groutec coupler is first screwed onto the reinforcement prepared at the precast factory, installed flush with the formwork, after which the element is concreted.

The connection is then completed at the construction site, where the precast element is positioned next to the adjacent element so that its protruding bars enter the cavities inside the Groutec couplers. The cavities are then filled with grout, either by gravity or by means of a grouting pump.

Groutec couplers have been designed to work with grouts commonly-available on the market place. Grouts must be cementitious non- shrink types, with a minimum compressive strength of 65 MPa.

Groutec has two alternative modes available.

Groutec L has a wide body allowing for more tolerance for the connection of two precast elements.

Groutec S (slim body) can be used in compact applications such as slim panels or narrow columns.

Groutec has been tested with grouts from major manufacturers such as Sika, Parex- Davco, Fosroc and BASF, which have a worldwide distribution network. However, attention is raised to the fact that such cement-based products are often produced locally from local raw materials and that their properties vary depending not only on their origin but also on climate conditions.

For first-time users, we strongly recommend that prior tests be carried in order to confirm the suitability of the selected grout.

For more information, visit:

www.dextragroup.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.