India’s first longest white topped road gets Recron Reinforcement

This article explains benefits of Recron3s fibre-reinforced concrete pavements with a case study of NICE Road, Bengaluru – India’s longest white-topped road using Recron3S fibres.

In a developing country like India, road networks form the arteries of the nation. A pavement is the layered structure on which vehicles travel. It serves two purposes, namely, to provide a comfortable and durable surface for vehicles, and to reduce stresses on underlying soils. In India, the traditional system of bituminous pavements is widely used. Locally available cement concrete is a better substitute to bitumen which is the by product in distillation of imported petroleum crude. It is a known fact that petroleum and its by-products are dooming day by day. Whenever we think of a road construction in India it is taken for granted that it would be a bituminous pavement and there are very rare chances for thinking of an alternative like concrete pavements.

Within two to three decades bituminous pavement would be a history and thus the need for an alternative is very essential. The perfect solution would be synthetic Fibre-Reinforced Concrete (FRC) pavements, as it satisfies two of the much demanded requirements of pavement material in India, economy and reduced pollution. It also has several other advantages like longer life, low maintenance cost, fuel efficiency, good riding quality, increased load carrying capacity and impermeability to water over flexible pavements.

FRC pavements are more efficient than ordinary cement concrete pavement. FRC is defined as composite material consisting of concrete reinforced with discrete randomly but uniformly dispersed short length fibres. The fibres may be of steel, synthetic or natural materials. FRC is considered to be a material of improved properties and not as reinforced cement concrete whereas reinforcement is provided for local strengthening of concrete in tension region. Fibres generally used in cement concrete pavements are steel fibres and organic synthetic polymer fibres such as polyester or polypropylene.

Fibre Reinforced Concrete

Concrete is well known as a brittle material when subjected to normal stresses and impact loading, especially, with its tensile strength being just one tenth of its compressive strength. It is only common knowledge that, concrete members are reinforced with continuous reinforcing bars to withstand tensile stresses, to compensate for the lack of ductility and is also adopted to overcome high potential tensile stresses and shear stresses at critical location in a concrete member.

Even though the addition of steel reinforcement significantly increases the strength of the concrete, the development of micro-cracks must be controlled to produce concrete with homogenous tensile properties.

The introduction of fibres was brought into consideration, as a solution to develop concrete with enhanced flexural and tensile strength, which is a new form of binder that could combine Portland cement in bonding with cement matrices.

Fibres are generally discontinuous, randomly distributed throughout the cement matrices. Referring to the American Concrete Institute (ACI) committee 544, in FRC there are four categories namely:

• SFRC – Steel Fibre-Reinforced Concrete

• GFRC – Glass Fibre-Reinforced Concrete

• SNFRC – Synthetic Fibre-Reinforced Concrete

• NFRC – Natural Fibre-Reinforced Concrete.

FRC can be defined as a composite material consisting of mixtures of cement, mortar or concrete with discontinuous, discrete, uniformly dispersed suitable fibres. Continuous meshes, woven fabrics and long wires or rods are not considered to be discrete fibres.

FRC is concrete containing fibrous material which increases its structural integrity. It contains short discrete fibres that are uniformly distributed and randomly oriented. Fibres may generally be classified into two: organic and inorganic. Inorganic fibres include Steel fibres and Glass fibres, whereas organic fibres include natural fibres like coconut, sisal, wood, bamboo, jute, sugarcane, etc and synthetic fibres based on Acrylic, Carbon, Polypropylene, Polyethylene, Nylon, Aramid, and Polyester. Within these different fibres the character of FRC changes with varying concretes, fibre materials, geometries, distribution, orientation and densities.

Fibres are usually used in concrete to control cracking in its’ Plastic and Drying states. They also lower the permeability of concrete and thus reduce bleeding of water. Some types of fibres produce greater impact, abrasion and shatter resistance in concrete.

The amount of fibres added to a concrete mix is measured as a percentage of the total volume of the composite (concrete and fibres) termed volume fraction (Vf). Vf typically ranges from 0.1 to 3 per cent. Aspect ratio (l/d) is calculated by dividing fibre length (l) by its diameter (d). Fibres with a non-circular cross section use an equivalent diameter for the calculation of aspect ratio. If the modulus of elasticity of the fibre is higher than the matrix (concrete or mortar binder), they help to carry the load by increasing the tensile strength of the material. Fibres which are too long tend to “ball” in the mix and create workability problems.

Polymer Synthetic Fibre Reinforced Concrete (PSFRC)

Polymeric fibres are gaining popularity because of its properties like zero risk of corrosion and cost effectiveness. The polymeric fibres commonly used are Recron3s – Polyester and Polypropylene. These fibres act as crack arresters, restricting the development of cracks and thus transforming a brittle material into a strong composite with superior crack resistance, improved ductility and distinctive post cracking behaviour prior to failure.

Concrete pavements may be weak in tension and against impact, but PFRC is a suitable material which may be used for cement concrete pavement as it possesses extra strength in flexural fatigue and impact etc. The usage of fibres in combination with concrete also results in a mix with improved early resistance to plastic shrinkage cracking and thereby protects the concrete from drying shrinkage cracks. It accomplishes improved durability and reduced surface water permeability of concrete. It reduces the risk of plastic settlement cracking over rebar. It enables easier and smoother finishing. It also helps to achieve reduced bleeding of water to surface during concrete placement, which inhibits the migration of cement and sand to the surface and the benefits of the above will be harder, more durable surface with better abrasion resistance.

A uniform distribution of fibres throughout the concrete improves the homogeneity of the concrete matrix. It also facilitates reduced water absorption, greater impact resistance, enhanced flexural strength and tensile strength of concrete.

Case Study of India’s longest white-topped concrete road using Recron3S Fibres

Project—Bangalore-Mysore Infrastructure Corridor Project (BMICP) – NECE Ltd.-Nandi Economic Corridor Enterprises Limited.

Project salient features

• First white-topped project in India – completed in May 2013.

• Longest white-topped concrete road in India – 90 lane km.

• First white-topped project under PPP model.

• Designed for 489 MSA.

• Design life of 60 years.

• Project using fibres for entire white-topping of around 72,000 cu.m of concrete.

• Project completed with least time and cost overrun, completed in 120 days using RMC.

• Concrete pavement is light in colour adding to luminosity during night thereby saving energy.

• Project executed without cutting a single tree and saving environment.

• Albedo effect—Surface being light in colour compared to bitumen roads reduces surface temperature (Heat Island effect) having substantial effect in less heat radiation to the surroundings.

• Savings in natural aggregates as design life is 60 years.

Design & Construction features

• Composite rigid pavement construction with M-40 grade of RMC with designed flexural strength of 5.2 N/mm2.

• Use of fibre reinforced M-40 grade of concrete for entire 72,000 cu.m with the aid of site based RMC plant of high capacity of 120 cu.m/hour.

• Highly mechanised paver operation used for laying concrete.

• Effective use of curing compound replacing conventional water curing system for concrete.

• No use of dowel bars/reinforcements for the entire 90 lane km.

• Laying of concrete with joints/grooves of 1m X 1m panels.

Mix Design Details

Pavement Design

The base coarse of Dry Lean Concrete (DLC) serves as working platform for supporting PFRC slabs which by slab action distributes the wheel load to larger area. The DLC base layer rests on granular sub-base which rest on sub grade.

Over the well compacted sub grade granular sub base is constructed using big stone boulders and mud.

Over that the DLC of mix 1:4:8 is made, which is compacted, levelled and floated. Surface of DLC is also corrected for road camber. An antifriction separation membrane of 125 micron thickness is spread over the DLC surface so as to impart free movement of the upper slab caused due to temperature warping stresses. The separation membrane may be stuck to the lower layer with patches of adhesives or appropriate tape or concrete nails with washer so that polythene sheet does not move during placement of concrete.

Many of the thickness design methods for cement concrete pavement adopted internationally derive their origin from the method evolved by Portland Cement Association (PCA). In this technology thickness of the pavement is assumed on trial basis. When dewatered concrete is provided on lean concrete, it has no problem of water being coming out on surface during compaction process but when it is done over WBM, a considerable amount of water is soaked by WBM and thus the concrete loses the water to WMB and the water which comes out during dewatering/ compaction process is not in same quantity as in case of lean concrete. It appears that it is better to provide base concrete than WBM as the base.

Due to repeated application of flexural stresses by the traffic loads, progressive fatigue damage takes place in the cement concrete slab in the form of cracks especially when the applied stress in terms of flexural strength of concrete is high. The ratio between the flexural stress due to the load and the flexural strength is termed as the stress ratio (SR). If the SR is less than 0.45, the concrete pavement is expected to sustain infinite number repetitions. As the SR decreases the no. of load repetitions required to cause cracking increases. This is also considered in the design of pavement.

Polymeric fibres normally used are either Polyester Polypropylene. It should be 100 per cent virgin synthetic fibre size 12 mm long and of 8 to 15 denier in diameter. It shall be mixed at the rate of 900 gms per cum of concrete. These fibres reduce plastic shrinkage and substance cracking. Use of fibres increases the toughness and post cracking integrity. Recron3S fibres are manufactured by Reliance Industries Ltd.

Polypropylene is one of the cheapest and abundantly available polymers. Polypropylene fibres are resistant to most chemical attacks. Its melting point is high (about 165 degrees C) so that it can withstand a working temp, as (100 degree C) for short periods without any detrimental effect to its properties. Polypropylene fibres being hydrophobic and can be easily mixed. Polypropylene short fibres in small volume fractions between 0.1 per cent to 0.6 per cent are commercially used in concrete.

Requirements for paving operations

• Use of microfilm or antifriction layer of 125 micron in between PFRC and DLC layers.

• DLC layer is to be swept clean of all the extraneous materials before applying microfilm which may be nailed to the DLC layer without wrinkles and holes.

• Concreting work in hot weather should be carried out in early or later hours.

• Laying temperature of concrete should always be below 35 degree C.

Curing

Membrane curing is applied with the help of texture-cum-curing machine. The resin based curing compound is used at the rate of 300 ml per square meter of the slab area. After about 1.5 hours moist Hessian cloth is spread over the surface covered with curing compound spray.

Protection and maintenance

The joint groove is to be protected from ingress of dirt or any foreign matter by inserting performed neoprene sealant. To exercise a very stringent quality control the test are to be conducted on fine and coarse stone aggregates, water cement, granular sub base, DLC etc as per standards and specification published by Indian roads congress.

Advantages and disadvantages

Advantages

• Water logging is a major reason for potholes in roads. WBM and asphalt roads are permeable to water which damages the road and sub grade. But PFRC roads are highly impermeable to water so they will not allow water logging and water being coming out on surface from sub grade.

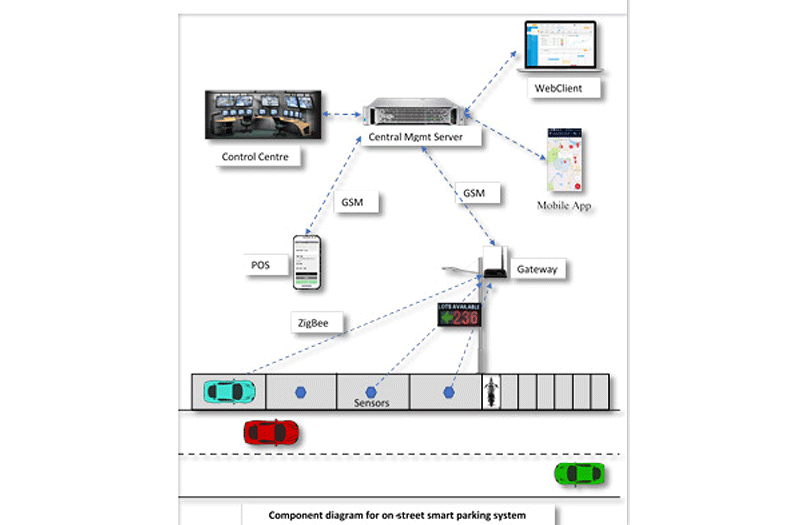

• Implementation of sensors in roads will be easier while using polymer fibres for concrete.

• Environmental load of PFRC pavement was found to be significantly lower than the steel fibre reinforced pavement.

• Maintenance activities related to steel corrosion will be reduced while using PFRC.

• In fresh concrete polymer fibres reduces the settlement of aggregate particles from pavement surface resulting in an impermeable and more durable, skid resistant pavement.

• Fibres reduce plastic shrinkage and substance cracking. Fibres also provide residual strength after occurrence of cracking.

• The use of PFRC produces concrete of improved abrasion resistance and impact resistance.

• PFRC also enhances ductile and flexural toughness of concrete.

• All these advantages result in overall improved durability of pavement and ensuring design life with drastic reduction in long term maintenance costs.

Disadvantage

The use of PFRC, being a relatively new technology, poses a threat of a high initial cost of construction.

Applications of PFRC

• Slab on grade: All types of pavements and overlays, industrial floors, roads, taxi ways, hangars, etc.

• Structural concrete: Foundations (deep and shallow), machine foundation, slabs, column beams and lintel, bridge decks and girders etc.

• Water retaining structures: RCC retaining walls, water tanks, cross drains, swimming pools, hydel projects, check dams, canal lining, ETPs, jetties, ports, spillways etc.

• Water proofing in rooftops, sunken toilets, etc.

Conclusion

PFRC can be used advantageously over normal concrete pavement. Polymeric fibres such as polyester or polypropylene are being used due to their cost effective as well as corrosion resistance. PFRC requires specific design considerations and construction procedures to obtain optimum performance. The higher initial cost by 15-20 per cent is counterbalanced by the reduction in maintenance and rehabilitation operations, making PFRC cheaper than flexible pavement by 30-35 per cent. In a fast developing and vast country like India, road networks ensure mobility of resources, communication and in turn contribute to growth and development. Resistance to change though however small disturbs our society; hence we are always reluctant to accept even the best. It’s high time that we overcome the resistance and reach for the peaks. PFRC opens a new hope to developing and globalising the quality and reshaping the face of the “True Indian Roads”.

Authored by__

KRS Narayan

M.S.-Leed’s Univ.-U.K.,

F.ICI., F.ACCE., M.IRC.,

Head-Technical Services & Market Development,

Reliance Industries Ltd.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.