PC-based control simplifies building revitalisation

PC-based building automation from Beckhoff is characterised by its system openness, reliability, ease of use and long-term product availability. In the revitalisation of the Eurotheum high-rise building in Frankfurt, Germany, Herrmann GmbH & Co. KG, benefited from these features in several ways. Having implemented the building’s original automation platform and the smoke extraction system in 2000, the system integrator was able to upgrade it substantially in 2018 with minimal effort in terms of time and technology.

At 110 metres tall, the office and hotel complex in the centre of Frankfurt stood out from the beginning due to its size and extremely flexible leasing options. While eight floors plus the lobby are occupied by a hotel with conventionally-automated building operations, 21 of the 31 floors can be subdivided based on the tenant’s needs and leased even on short notice in units of 240 square metres or larger. Available layouts include open concept floor plans, office setups with rooms or cubicles or a combination of the above. Essential for the flexibility of use is easily adaptable room control for building services such as heating and cooling, lighting and shading, enabling customised floor layout with little effort.

Hansjörg Ludwig, General Manager of system integrator Herrmann, explains the original requirements, “Room sizes and floor layouts had to be modifiable within a specified timeframe. We accomplished this by establishing a 1.35-metre grid based on the width of the windows that allows each segment along a window axis to be flexibly assigned. This flexibility made it possible to achieve the original tenant’s goal of being able to configure e.g. three single offices or a single conference room in the same space for its frequently changing teams within 24 hours.”

Flexible building automation makes all the difference

Besides reconfigurable room walls, such a building requires highly flexible automation systems, says Herrmann Team Manager Rainer Daiß, “The infrastructure endpoints for HVAC control stay in place, as do all the sensors and actuators, blinds and the lighting control elements. The building operator, however, must be able to modify the interaction of these data points with higher-level building controls, and this can be accomplished via a user-friendly configuration tool in the central building control system. In addition, the advanced single-room controls feature three operating modes set for comfort, economy and night-time operation. The rooms are controlled automatically, depending on the time of day and the presence of occupants determined via occupancy buttons, but can all be individually adjusted as well.”

Revitalisation improves reliability, protects investments

Herrmann opted to implement Beckhoff Industrial PCs (IPCs) from the building start. Rainer Daiß says, “To connect over 40,000 data points in the building control system, 20 C6130s were distributed across three floors. Today, 20 compact C6915 control cabinet PCs perform this job. Since they are much smaller, they could be distributed across the individual floors in a more space-efficient manner with a floor manager on each floor.”

According to Michael Herrmann, high flexibility of PC-based control was another major factor in the building revitalisation project as it gives comprehensive toolbox that aids implementation of all specific requirements of a building quickly and with minimum effort.

“We can integrate legacy systems that are still in good working order and carry out revitalisation projects without having to interrupt building operation,” he says.

The same applies to TwinCAT automation software, adds Rainer Daiß, “No comparably flexible software system was available at the time. It also offers the benefits of efficient engineering and upward compatibility, which is critical for long-term operational reliability.”

Hansjörg Ludwig considers long-term availability and reliability to be crucial for upgrading the I/O system as well. “Some of the legacy Interbus components had been discontinued, which can cause problems as in past, particularly in commercial buildings that are designed for many years of use. In addition, many I/O components were installed in ceiling-mounted distribution boxes, overhead. However, the extensive diagnostic capabilities of the EtherCAT system make it much easier to find exact points of failure.”

EtherCAT for smoke extraction and building automation

The complexity of Eurotheum is reflected in its many physical data points alone after revitalisation: 100,000

for the building automation features and an additional 6,000 for the smoke extraction system. Accordingly, having powerful data communication capabilities is critical

The huge volumes of data generated require an exceptionally fast and reliable bus system like EtherCAT that can operate over copper wires just as well as over fibre-optic cables, depending on the circumstances. Cable redundancy and fast fibre-optic cable installation suits highly available smoke extraction system.

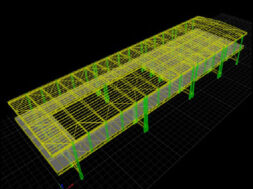

The smoke extraction system is controlled by two CX2030 Embedded PCs. They connect two separate EtherCAT loops that run through all building floors. The system employs a total of 74 EK1501 EtherCAT Couplers along with 450 EL1008 digital input terminals and 150 EL2008 digital output terminals. Based on the information supplied by these components, the smoke extraction system is able to identify one of approximately 50 smoke extraction scenarios and will accordingly turn the appropriate exhaust fans on or off and open or close fire dampers. To do this, the Beckhoff control system communicates with the building management system over an OPC server via ADS.

Data transmission of the room automation systems for each floor also runs over an EtherCAT loop that connects the four switching panel alcoves as interfaces to the individual trade systems. Each of the 20 floors has 34 distribution racks and 38 BK1150 Bus Couplers to handle the typical building data via M-Bus, KNX, Dali and DSI, as well as the legacy Interbus network for the HVAC systems. In addition, each floor has 15 EP2008 I/O box modules linked to an EtherCAT loop that are used to control the heating valves in a particularly space-saving manner.

For any further information, please visit www.beckhoff.co.in

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.