Putzmeister to deliver 1,000th Truck Mounted Concrete Boom Pump

Putzmeister Truck Mounted Boom Pumps have worked on major metro, bridge, refinery and thermal power plant projects in India.

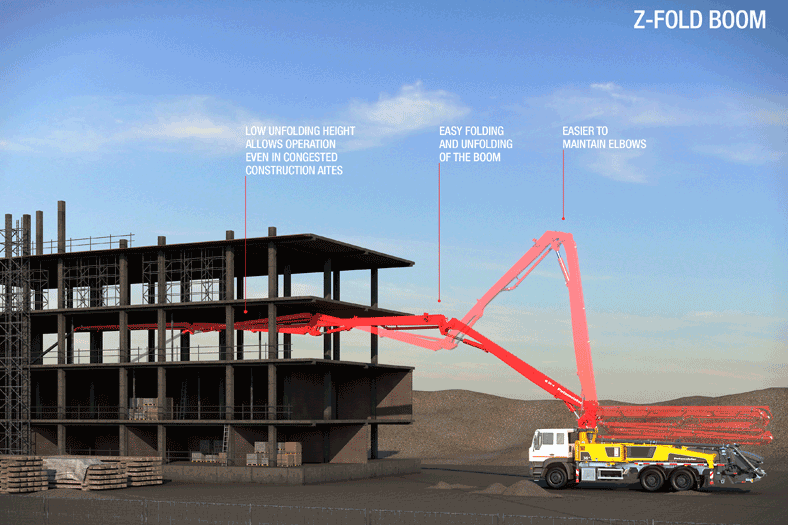

Putzmeister is gearing up to deliver the 1,000th Putzmeister Truck Mounted Boom Pump from its factory in Goa, India this month. Putzmeister offers these truck mounted pumps in three configurations – 36 meters (4 arm, Z fold), 42 meters (5 arm, RZ fold) and 47 meters (5 arm, RZ fold) to customers in India, Nepal, Bangladesh, Bhutan, Sri Lanka and Maldives.

Headquartered in Germany, Putzmeister set up operations in India as early as 1997 and commenced production from its plant in Goa in 2007. Since its inception, the company has established itself as a leader in concrete pumps. Superior performance, reliability, long service life and lower long-term cost of ownership are the hallmarks of Putzmeister Truck Mounted Boom Pumps. Unbeatable maneuverability, flexibility and optimum use of reach have helped catapult these pumps to a leadership position in India.

Putzmeister Truck Mounted Boom Pumps have worked on major metro, bridge, refinery and thermal power plant projects in India. Globally these pumps are renowned for their ability to work across a range of application conditions and extremely harsh environments, including radioactive environments. In 1986, Putzmeister Truck Mounted Boom Pumps were put into action to help seal the Chernobyl Nuclear Reactor in a concrete sarcophagus. The machines pumped 400,000 cubic meters of concrete to seal the reactor. In 2011, Putzmeister Boom Pumps were adapted to pump water (160,000 litres per hour at a pressure of 85 bar) instead of concrete to help cool down the Fukushima Nuclear Reactor.

The company is currently in the process of rolling out Putzmeister Machine Cockpit on its fleet of Boom Pumps in India. This will allow fleet owners to optimize their machine uptime and fuel consumption. Remote fault monitoring will enable quicker fixes. Automated maintenance alerts will improve equipment management. And ofcourse fleet owners will know where their machine is at all times – ensuring no unauthorised movement or use.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.