The Art of Bridge Building

Formworks and scaffolding forms an essential component for bridge building in india as it provides speed of erection,safety,cost-efficiency and flexibility for longer period.

Scaffolding is an aged practice of using bamboo materials previously. The necessity for speedy erection in lesser time with demand for higher safety, longer life coupled with flexibility in size and cost has drive out the use of bamboo. Now, with the rising awareness of ease of access, more and more building owners are opting for modern methods of scaffolding and formwork and getting rid of bamboo materials.

Scaffolding has become extremely admired in the Indian region. As the continent is developing its infrastructure, the need for better and more consistent construction strategies is on the rise. Over the years, better scaffolding materials and equipment have been made accessible to contractors. As of now, scaffolding is a crucial component of every construction process since it keeps workers safe and makes the process easier.

Formwork is used by creating moulds out of wood, steel, aluminium or prefabricated forms into which the concrete is poured. This is then allowed to harden and set after which it is stripped or in the case of stay-in-place formwork it is left as part of the structure.

The shift has been towards the high efficient formwork and scaffolding systems, particularly self-climbing formwork systems and slab table form system formwork. The age-old timber based poles scaffolding has made way for the pre-engineered systems made of aluminium, plywood, steel etc. Contemporary formwork and scaffolding systems are attractive in particular for their speed of erection, safety, cost-efficiency and flexibility.

Furthermore, its new, self-climbing version of the table lifting system (TLS) makes it possible to form floor-slabs 100 per cent crane-less, as well as enhancing safety during the lifting operation.

Likewise, new technologies are entering Indian market. Climbing formwork systems, automatic climbing systems, aluminium and timber based scaffolding and formwork systems are some of the instance.

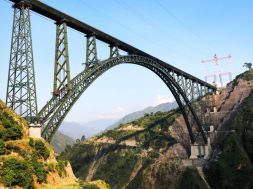

Formworks and scaffolding facilitate bridge construction

Raj Lakhani, Managing Director, PERI (India) Pvt Ltd says, “Infrastructure development is the need of the hour for the Indian economy – be it roads, railways, metro-rail, airports or affordable housing. Construction of bridges is at core of any development for roads, railways and metro rail. During ancient times, wooden beam bridges helped in developing human civilisation. Due to increased urbanisation, traffic developed alongside infrastructure networks, which also included river and valley crossings. Technical advancement enabled increasingly challenging bridge constructions.”

Modern bridge construction demands technologies which are faster, safe and innovative. For nearly 50 years, PERI products and systems have successfully proved themselves in the market globally. PERI has developed ground breaking formwork and scaffolding technologies which continues to set standards in the industry, he adds.

In 2017, PERI India celebrated its 10th anniversary. Innovation supported by adequate R&D is a key driver for our growth. With landmark projects such as Mahatma Mandir, the Statue of Unity, Agra-Lucknow Expressway, Hyderabad Metro, using our state-of-art formwork and scaffolding system, we

have proved our mettle in delivering customised solutions for every complex need in a cost-effective manner.

Sachin Yadav, Director Sales, Doka India says, “Bridge is a massive structure built to span physical obstacles without closing the way underneath. There are various types of bridges like beam bridge, cantilever bridge, arched bridge, suspension bridge, cable stayed bridge double decked bridge viaducts etc. Apart from this a single bridge is consists of different segments like pier pylon foundation etc. Each of it has a different geometry and requirement.”

Advantages of formwork over conventional

Every bridge is unique – as is the associated formwork solution. The basis for developing a custom-tailored formwork solution is laid by consultation and support for the project from the very start. Doka experts discuss the requirements in detail with customers. The ability of the formwork products to integrate with each other simplified the process when more than one product was needed. Additionally, since these projects have innovative elements to the design, ingenuity and inventive thinking were required of the form supplier. For example, all of the forms from the pier table to the traveller had to allow for not only geometry changes but also field changes. This required flexibility that could not have been accomplished with the use of the Conventional system.

Doka’s solutions for bridge formwork

Doka Systems like Top 50 ultimate solution to customised designs and load bearing towers like Staxo 100 and D3 along with climbing systems are the complete solution and manifested their eminence for Bridge formwork around the globe. In addition, Doka has invented new systems like Dokashore with high load bearing capacity up to 430 KN and unikit which is a modular system grid makes it adaptable to different structure geometries.

A case study

NHAI has constructed six lane highways over Chambal river. The project includes total 43 piers for bridge with varying height of 27-metre. The pier size at bottom was 7,500 mm x 2,500 mm and at top is 7,000 mm x 2,000 mm (i.e. reduction of 500 mm) semi-circular at both the end. Also, it has limited access to crane as it is over a river.

PERI provided solution with hydraulic climbing system RCS along with VARIO formwork system. Customised solution was provided with adaptor in order to climb the system.

Vijay Mistry construction Pvt Ltd was contractor for the project. They could complete project faster with two sets of VARIO formwork system. One set for 7,500 mm x 2,500 mm and another set for 7,000 mm x 2,000 mm size reduced the cycle time to four days.

PERI India has recently launched ALPHAKIT, which is an engineering construction kit for various applications like bridges, TG sections, cantilever beams and slabs.

Modern bridge construction demands technologies which are faster, safe and innovative

Raj Lakhani, Managing Director, PERI (India) Pvt Ltd

The basis for developing a custom-tailored formwork solution is laid by consultation and support for the project from the very start.

Sachin Yadav, Director Sales, Doka India

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.