Dextra showcases its unique solutions in Suvarnabhumi Airport construction, Thailand

Suvarnabhumi Airport is Thailand’s main international airport, serving both domestic and international flights as one of the region’s main gateways to Southeast Asia. The airport is located in the eastern part of Bangkok, the capital city of Thailand. Dextra has been a part of the project since its inception in 2001 and it continues to provide support to the airport’s most recent expansion projects by supplying a wide range of engineered construction solutions for various parties.

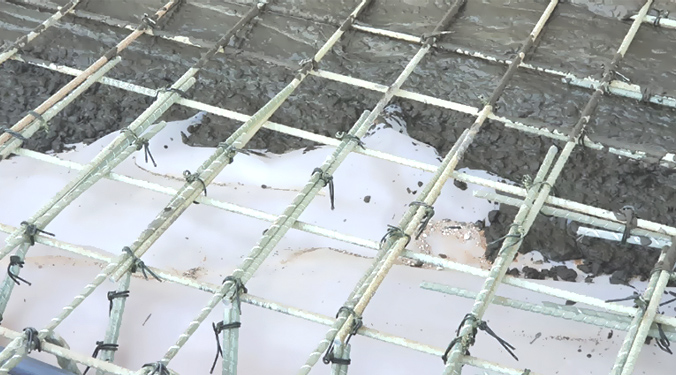

Bartec rebar couplers have been extensively applied in the airport structures, including foundation piles, diaphragm walls, columns and beams, and other concrete structures. The well-known splicing systems allow for the safe connection of rebar, either vertically or horizontally. Dextra also manages the rebar threading service using the trustworthy equipment stationed in Bangkok. Rebar coupler systems, sometimes also known as mechanical splices, are used as an alternative to traditional lap splices in concrete.

They transmit the rebar load directly from one rebar to another without relying on concrete bond, concrete strength, or the condition of the concrete surrounding the rebar and coupler. Mechanical rebar couplers create a continuity of reinforcement which is not reliant on the quality or integrity of the concrete. Their use creates less rebar congestion, more convenient and often

safer site practice as well as reducing the amount of steel used. While different performance levels exist for rebar couplers, a guaranteed “bar break” coupler means that there will ultimately be no brittle failure in a ‘beyond design” event and the full ductility of the rebar will be maintained, a feature which is recommended in safety critical applications or if the structure could be subject to impact damage or a seismic event.

The airport’s terminal roofs and concourses have also been designed to use Dextra Tension Rod systems as cross-trusses. Thanks to the systems’ fork ends and in-line connectors, the rods are simple to install and adjust in length, and they contribute to the overall aesthetics of the terminal structure. Tension Rod systems’ typical applications include hangers and supports, cross bracing and truss stiffening elements. A number of different strength grades and surface finishes were supplied at the site. The systems offer an aesthetic and high-performance solution for tensile members for the airport structure.Sonitec, a crosshole sonic logging (CSL) concrete testing tube, were also supplied to facilitate the integrity testing of foundations.

The system was chosen for the purpose of facilitating the assembly and installation of long tube lengths in reinforcement cages. Moreover, Dextra supplied large diameter Fiber Reinforced Polymer (FRP) dowel bars to connect the concrete slabs in the plane remote parking area where planes fine tune communication with the control tower. Our FRP rebars have similar tensile properties to traditional steel rebars while avoiding some of the interferences that are inherent in metallic structures such as magnetic interference and corrosion. Dextra is a leader of the composite industry for the past 25 years, manufacturing high quality FRP solutions supplied on large infrastructure projects. All FRP rebars are produced in Dextra ISO-9001 and ISO-14001 certified factory, following the company stringent quality assurance policy.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.