Enhancing indoor comfort at airports

State-of-the-art HVAC and insulation solutions that can improve indoor comfort at airports

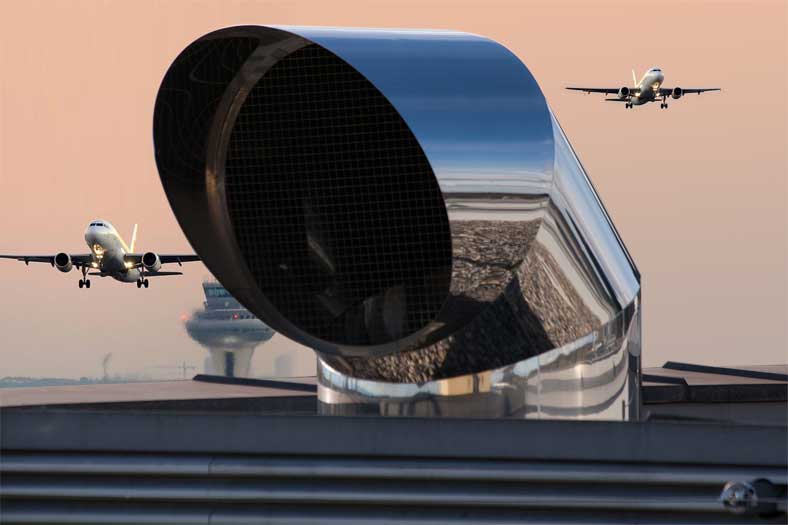

Demand of air travel is at an all-time high and is growing at an unprecedented rate. As per the latest Google and BCG report, India’s domestic travel market to be $48 billion by 2020. However, with the increase in traffic, this growth will be constrained by capacity-issues in air space at airports. Though airport buildings are ventilated to provide breathing air for human comfort and health, large amounts of external air are drawn into airport buildings, heavily polluting the indoor air. Airplanes are not the only source of pollution at airports ground traffic levels, air pollution together with the direction of the prevailing wind all contribute to it. “Bringing in our insights from a study conducted by Camfil at a major European airport, we can conclude that a high proportion of pollutants in the ventilation system were mainly due to diesel emissions by commercial vehicles operating in proximity to the gates,” states PKSV Sagar, Managing Director, Camfil Air filtration Pvt Ltd.

Camfil is continuously working towards clean air solutions that improve indoor air quality at hotels, offices, hospitals, museums, educational institutions and airports. Briefing about its offering that can improve indoor comfort at airports Sagar says, “We offer a varied range of air-filters and filtration systems that can efficiently tackle any type of particulate and molecular pollutants generated from external and internal sources. Depending on the extent of the problem, these range from three different categories-particle (30/30, HI-FLO, opakfil, absolute hepa), molecular (camcarb CG, city sorb and camcarb VG 300) and combination (city carb, and city flo) filters.”

Among these, opakfil and city sorb are ideal choices for high levels of indoor air quality (IAQ), with an optimised filter design. In addition to being highly efficient in tackling pollutants, Camfil filters have the distinction of being highly energy effective due to lower pressure resistances, Sagar claims.

Being fully compliant with the recommendations of the latest European Standard for IAQ: EN13779, and ISO 16890 (for particulate filters) Camfil products satisfy all demands from airports to eliminate pollutants and provide clean air that is comfortable and healthy for the travelling public and their staff.

Ventilation is a top priority for most airports to facilitate traveller comfort and safety. However, there exists a need to combat rising electricity prices, optimise the utilisation of air handling units and reduce energy consumption. Danfoss offers a wide range of energy efficient solutions using the latest technology, while staying true to its commitment to reduce carbon footprints.

Informing about the company’s offering Ravichandran Purushothaman, President, Danfoss Industries Pvt. Ltd says, “Danfoss VLT HVAC Drives extend from low to high-power solutions, equipped with HVAC- dedicated functionalities, compatible soft starters and filters for EMC and harmonic mitigation. We also deliver a complete range of field bus communications options that enable effective integration with the building automation systems.”

He adds, “With the help of our integrated solutions, the Belfast International Airport which handles close to 5,000,000 passengers a year was able to reduce its carbon emissions by 500 tonne per year.”

He adds, “Our FCD300 Decentral drive is an industry leader that provides the most extensive range of solutions to facilitate quick and efficient functioning of baggage handling conveyors that can transport and sort baggage weighing up to 100 kilograms at speeds between 1.8m/s and 15m/s.”

Danfoss’s also partnered with the Mumbai International Airport that created a new benchmark in the history of airports with their efficient design, commitment to the planet and world class passenger services which paved its way.

Danfoss drives also find their use in Air Handling Units (AHUs), chillers, elevators and escalators in airports around the world that values innovation and sustainability.

“AC drives control the power supply to electric motors and typically save 15-40 per cent of energy consumed. 40 per cent of electrical energy consumption in the world is by electrical motors. Global electrical energy consumption could be reduced by 10 per cent if AC drives were used in every suitable application. This spurs theglobal demand for Variable Frequency Drives (VFD), which is expected to increase at over 7 per cent Compound Annual Growth Rate (CAGR) during the period 2016-2026,” informs Purushothaman.

In the age of innovation, organisations committed to sustainability stand out. Danfoss has always been a supporter of corporate citizenship and sustainability. “We are committed to Cop 21 and UN Global Compact. Today, more individuals and industries are realising their commitment towards our planet. At Danfoss, we are dedicated to fulfilling our mission to engineer a better tomorrow,” says Purushothaman.

He claims, “Engineering Tomorrow is the essence of Danfoss’ identity – coupling Danfoss’ innovative engineering and respected quality and reliability with a constant desire to drive growth and realise the potential of tomorrow.”

According to Sanjeev Sseth, Country Leader- HVAC and Transport, Climate Solutions, India and Saarc Markets – API SBU, Ingersoll Rand, acceptable human comfort is much more than providing a prescribed volume of air per person. In order to share a good level of comfort, both temperature and RH plays a critical role. Trane believes that good HVAC system selection and design, specification of equipment and furnishings, along with proper building operation and maintenance are the foundations of comfort and quality indoor air.

Sseth says, “Comfortable and hygienic air quality for an airport can only be achieved when all the variables of IAQ like temperature, humidity, particulate count, odors, fresh air volume and circulation are well controlled and maintained. Each of these criteria requires effective management both at the equipment and the building control levels. Air handler selection has also a direct impact on comfort, air cleanliness, the health of the people in the airport and insuring proper air movement.”

He adds, “Custom AHUs can play the prefect role in this case. They generally have the highest quality construction and are most commonly used in institutional or industrial applications where high flow rates, very close control, and harsh conditions exist. Custom units can be configured to include virtually any combination of air processing components. They also can include walkways and service areas within them and can even accommodate space for skid-mounted equipment like pumps or heat exchangers.”

Trane offers the following products to maintain indoor comfort at airports:

• Trane’s Cool Dry Quite (CDQ) AHU with a desiccant wheel, it enhances the dehumidification performance of a cooling coil thereby increasing latent capacity. These units not only help to control the temperature but allow greater indoor comfort without the need for a second regeneration air stream and it saves energy. This is also AHRI certified performance.

• CLCP Quantum Climate Changer it is an exclusive product for comfort applications, with every CLCP AHU building requirements turns into business advantages by supporting energy efficiency and maximise indoor air quality which can also be customised solutions for Airport. These are Eurovent Certified which can be integrated with wireless VAV.

• Wireless VAV With the new technologies and optimised controls, a Trane Intelligent Variable Air Volume System can deliver 20 to 30 per cent more efficiency than a traditional VAV system—and one can easily monitor that efficiency with user-friendly dashboards to help maintain peak performance for the life of the system.

CLCP is tested and certified for mechanical performance in accordance to European Standard prEN1886 for CLCP 50mm thermal break:

• Casing thermal bridging factor – Class TB2

• Casing strength – Class 2A (Highest class)

• Casing air leakage – Class B (Highest Class)

• Casing thermal transmittance – Class T2

• Filter bypass leakage – Class F9 (Highest Class).

Most public spaces like cinema theatre, shopping mall, airport etc are air-conditioned today, thus allowing very little fresh air and sunlight into the space. As a result there is huge proliferation of infectious substances, dust and other pollutants. Higher the density of occupants, cross infection rises. The times spent by us in these kinds of environments are on the rise because of our lifestyle demands. “As we all know very well, we breathe all 24 hours a day, the quality of air which goes inside us completely depends on the surrounding. If the surrounding is bad, quality inhaled is bad. Since most of the time, we consume air in closed AC rooms, this is resulting in exposure to poor quality of air,” notes Shuvendu Mazumdar, National Manager, SHARP Air Purifier Business.

Briefing on the company’s latest offering, he says, “Sharp’s unique Plasmacluster Technology helps in improving such public spaces. Sharp Plasmacluster technology has been verified by 28 global labs and with over 7 crore users worldwide this is undoubtedly the most safe and trusted air purification system.

The Sharp Air Steriliser Model IG-A20E has been designed for such applications where the threat of cross infection and smell is high. This has a front airflow making it most effective for flow or wall mounted Installations for safety and security.

Lloyd Insulations (India) Ltd identified its role in an airport terminal building to be that of ensuring the following to meet the situation and needs of a comfortable passenger;

By providing highest quality thermally insulated envelope, the company provide a barrier to protect against ingress of high external ambient temperatures with solar incidence in summer, thereby ensuring that the HVAC system is able to maintain air temperature within the built space at comfort levels at all times. In locations with colder climate, the thermal envelope barrier would protect against ingress of cold to ensure thermal comfort of the passenger.

By providing an effective barrier against noise transmission, the company ensures that the internal ambient noise level is well within hearing comfort levels in spite of the high noise levels outside due to take-off and landing of aircraft.

Lloyd Insulations provide acoustical treatment with correct level of absorption to result conducive condition for clarity and intelligibility of words delivered through the public address system so that the passenger does not miss important messages. These objectives have been met in our association with the Mumbai International Airport project- which has set a new standard for airports worldwide, concludes N Srinivas, Mentor, Lloyd Insulations (India) Ltd.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.