Durastrip: self-adhesive bitumen, butyl tapes

Rapid industrialisation in India after liberalisation of economy has contributed to immense growth in construction of the structures made of asbestos, GI (galvanised iron) and PEBs (pre-engineered buildings) among the latest in this category.

Depending upon the type of use, PEB structures are used to house packing and storing areas, shop floors, raw material storing areas, warehouses, manufacturing unit and big retail stores.

Problems encounteredWater seepages, leakages and ingress of dirt are common problems encountered in even in the most technically sound PEB structures. Sealing of joints is a challenging task for the following reasons:• Chemical waterproofing compounds fail to bond with the metal surfaces• The conventional waterproofing materials, after application, needs to be protected from the damages caused by ultraviolet rays. Any such protective covering will add to the dead load on PEB structures• The contours of PEB surfaces and its structural movements underneath calls for a waterproofing system to be flexible and resilient.

Solution offeredDurable products offer self-adhesive bitumen and butyl tapes, international quality, under the brand name Durastrip.

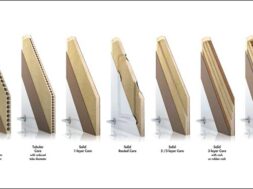

Durastrip is a self-adhesive composite product available in SBS bitumen and butyl-based compounds forming the core, reinforced with anti-tear aluminium covering with high-density polyethylene (HDPE) film on the top and silicon adhesive layer protected by release paper on the bottom for quick and lasting applications. It conforms to ASTM and EN standards.

Durastrip is used for waterproofing, sealing of existing and new structure of factories, warehouses, production units made of asbestos, GI, and mild steel. These tapes are available in form of 10-metre long reels in various widths like 50, 75, 100, and 150 mm.

Characteristics of DurastripDurastrip tapes offer instant bonding and are easy to use. It is compatible with all construction materials (metal, concrete, wood, FRP, and plastic), having high-flexibility, low-water permeability, and environmental stability with least dead weight on the structure.

Aluminium foil on the top protects the compound against ultraviolet rays and offers long-lasting durability with least life cycle cost.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.