Terex MACS plant offers new MVP450X cone crusher

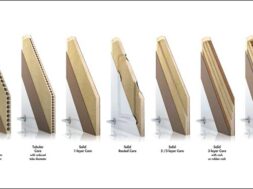

The Terex MACS plant is designed to be a highly mobile, high capacity, complete crushing and screening system. The MACS name stands for mobile aggregate crushing system because it is a complete system, not just a collection of individual processing units. MACS units are highly integrated with each other to increase production and reduce set-up time. No cranes or booms are required for set-up, all inter-plant conveyors are on board.

The MACS uses larger crushers and screens than what are typically used in track mounted or wheeled plants. And now, the MACS plant offers the newest generation Terex MVP450X cone crusher. The MVP450X boasts numerous features that increase productivity and ease of use. Major new enhancements include high-speed clearing of jammed material and quick crusher separation capability for faster manganese changes.

The MACS unique trailer designs allow easy mobility. The crushing and screening units travel under 4,115 mm high and under 3,660 mm wide. Interplant conveyors are designed into the units so that separate transfer conveyors are not required. Folding conveyors and walkways set up using on-board hydraulics, thus eliminating the need for cranes or lifts. Also, large hydraulic support legs level and stabilise the units to speed set-up.

MACS plant is not only designed for mobility and high production, but also for low cost of operation. The entire system uses industrial electric drives so that the system can be powered by either high efficiency generators or line power when available. The unique layout of the system provides operator visibility of the entire circuit from a central pop-up control house. High-quality belt wipers and skirted conveyors are used throughout to reduce spillage. Maintenance is reduced since all components such as gear boxes, belt idlers, pulley bearings, 3-ply vulcanised belts, and flashings are selected for long life and low maintenance. Instant cone reset, strategic rock shelves and the TOPS 2.0 oil filtration system are additional maintenance reducing features.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.