Satec Envir Engineering started its journey with manufacturing of shelters and towers; it expanded its business by entering into pre-fabricated structures and solar mounting structure. Today Satec is one of the premium names in the pre-fabricated structure market. It is growing at a phenomenal speed and has made a mark in the national and international markets. The company in true sense is positioning itself as next generation infrastructure company.

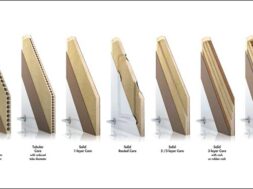

The core strength of its products, which are completely customised, is very economical as compared to conventional buildings material and completely movable from one location to other. Satec’s pre-fabricated structure stand out as it never compromises on the quality of the products. Its products can withstand high winds and seismic zone.Satec manufactures everything in-house and has invested in building a state-of-the-art production unit which spreads across 1, 40,000 sq. feet in Bhuj, Gujarat. Satec has top line PUF, continuous panel production machine, roll-forming machine, CNC plasma cutting machine, galvanising and power coating unit.

Satec is committed to innovation and offering multistorey fabricated buildings which are made of combination of cement cladding and steel. These attractive, extremely strong structures can be made in small time span and also are more economical than the conventional buildings.

Satec has recently acquired contract of to supply per fabricated residential colonies in Bhutan as well as completed work in Africa and Australia for low-cost residential colonies. It is also part of a prestigious coal power project in Jharkhand for supplying conveyor gallery and trestle and currently commissioned for 30 MW solar power project in Surender Nagar, Gujarat.

Looking ahead, Satec wants to work hand-in-hand with its clients as partners in their growth. As it believes that both internal and external clients are extremely important, it has left no corner untouched for safety and security of labour working at various sites and company.

Taking cues from the economic environment, Satec is continually upgrading its technology and striving to provide best solutions in pre-engineered, solar mounting modules and portable cabins verticals.

Popularity of low-cost housing gainingIndian growth story is still robust in spite other developed economies across the world, facing a hard time, especially in the infrastructure segment. This is due to various capital projects been undertaken by big corporate and also government spending money on development of railways, roads and other infrastructure needs across the country. In the 12th Five-Year Plan, the government has almost double the infrastructure development to 41 lakh crore. These figures also motivate steel structure players and portable cabin industry in the country. Portable cabin are needed across various sectors where mining and railway constructions are underway. These cabins can be easily re-located from one site to another and used for labour accommodation, site offices and storage area also. They are durable and can last even as long as 30 years if maintained well.

Satec is one of the leading names in the portable cabins industry with its promise of trust and quality. These fully modular, mobile cabins are the intelligent, cost-effective and efficient solution to site offices and residences.

The remote and open topography of mining sites, leave it vulnerable to harsh weather conditions like dust, heat, torrential downpours and cyclonic winds. Satec’s portable cabins are made to withstand extreme weather, making it an ideal solution for offices and residences for the mining industry.

Satec has established expertise in installing portable cabins at such sites; Satec has installed a unique re-locatable labour colony for various mining industry players, also one of the project sites where 200 portable cabins were supplied for 400 engineers.

Satec is also undertaking a key project in Bhutan for multinational company and providing portable cabins for an upcoming hydro power project. The company is using portable cabins for site offices, labour accommodation and various other purpose of almost setting up a small township for its official on difficult mountainous area. The very fact that the company has opted out for portable cabins over conventional buildings proves the viability of product in long run.

These cabins have become a popular choice in the infrastructure sector due to their resilient nature and ability to withstand harsh weather conditions across the places. The polyurethane material which is used for building these panels has insulating qualities.

Satec has been providing turnkey solutions to many leading companies like GPCL, Essar, Sun Edision, and so on.

Leaping into futureToday pre-engineering solutions are becoming a common trend in industrial sector and with India’s economy growing at a modest yet optimist way, Satec sees huge demand for pre- engineered and prefabricated products and service.

Satec is manufacturing prefab structure for over a decade now and has grown from providing telecom shelters to a leading manufacturer of sandwich panels, insulated roofing solutions, prefab porta cabins and shelters ground plus one building, solar mounting structures and pre-engineered buildings. The company believes in providing 360-degree solutions to its clients.

QualityProduct quality is crucial in this sector and Satec has ensured high quality through stringent quality norms and also has ISO 9001:2008 certification for quality management. Satec has in-house seven tank galvanising plant which ensures high quality zinc galvanising for solar and other pre-engineered products.

ProductionIts manufacturing unit has state-of-the-art machineries, and Satec ensures that all quality norms are adhering at its plant in Bhuj. The company provides customised products and has been working closely with its team of engineers and designers to ensure the cost efficiency of projects are kept intact. Its plant is well equipped with top of line panel manufacturing, and the company has two other lines for panel production which ensure timely completion of a project.

Latest technologyIts PEB manufacturing machines like H-beam manufacturing, automatic gantry type welding machine, H-type steel flange straightening machine and H-beam shot blasting machines are as per the latest technology practiced abroad. The company has always out preformed its competitors by employing latest international production technology.

These factors are seen working in its advantage to provide best solutions to its clients Satec has successfully completed various large orders in different segments of high-profile infrastructure organisation like Essar, JSPL, L&T, Marti, Welspun, Insolar, Juwi, Simplex and Ramboll.

Satec has done many innovative projects in the recent time. These include building ground plus one portable cabin for Jindal Steel and Power, Angul, Orissa. The ground plus one building structures helped create a comfortable home like stay for site workers and it was one of its kind design of low-cost housing design.

Satec has constructed several low-cost housing colonies for clients like Vedanta, Essar and JSPL extending to countries like Australia and Africa and now enters Bhutan. The company has gained trust in international market due to its reliable quality and excellent customer service.

Apart from prefab structures, Satec has started undertaking pre-engineered building projects. Company workshop is well equipped with H-beam welding machine and roll-forming machines for C and Z purlins. The company has capacity to undertake any size projects and is continuously striving for providing better solutions to its clients.

Satec has also undertaken projects in solar energy space and worked with leading solar power plant set-up by providing solar mounting module, including Narmada Canal Solar Power Generation Project.

3

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.