“The Pir Panjal Tunnel project offered HCC an opportunity to accomplish one more feat to construct the India’s longest tunnel in the young Himalayan region,” says Arun Karambelkar, President and Wholetime Director, Hindustan Construction Company Ltd.

Pir Panjal Railway Tunnel, which is India’s longest, is 100 per cent water proof and equipped with fire-fighting system. The methodology adopted for construction of this tunnel is by New Australian Tunnelling Method (NATM) where the geological stress from the surrounding rock is used to stabilise the tunnel hole. It is one of the challenging, marvellous projects in Indian civil engineering history. The tunnel is aligned straight from north to south for its length of 10.96 km.

The Pir Panjal Tunnel is a major part of Udhampur – Srinagar – Baramulla Broad Gauge rail line project. It is constructed in the rugged terrains of Pir Panjal pass in Jammu and Kashmir. It connects Bichleri Valley at the south with the Kashmir Valley on the north. The nearest towns in south and north side are Banihal and Quazigund, respectively. The quantum of work involves 1 million cum of underground excavation in the young Himalayan region with surprising geological challenges. IRCON International has taken up the construction job of the project from Dharam to Baramulla section, being an autonomous constructing agency for Indian Railway.

The railway line from Qazigund to Baramulla (119 km) was already completed by IRCON, and it is operational to public since October 2009. In order to accelerate the balance work, the total length between Dharam to Qazigund section was divided into six zones by IRCON and the contract was awarded to different agencies for early completion. The contract for zone IV and V has been executed by HCC, one of the pioneers in construction and infrastructure development. HCC has executed more than 170 280 km of tunnelling works at different locations with different technical challenges and completed majority of India’s landmark infrastructure projects in different sectors. The Pir Panjal Tunnel project offered HCC an opportunity to accomplish one more feat to construct the India’s longest tunnel in the young Himalayan region.

Project designIn order to shorten the critical length of the drive and isolate the soft ground near the portals, an ADIT and shaft was provided. The ADIT was constructed 2.75 km from the south portal and the shaft was constructed 610 metres from the north portal, which ultimately reduced the critical length as 7.6 km against the total length of 10.96 km. The total length of the ADIT is 772 metres. The diameter of the shaft is 12 metres with a depth of 55 metres, and it is connected to the main tunnel through a 36-metre cross passage. Construction of the tunnel had started in November 2005, and the project team completed the day lighting of the tunnel on October 2011.

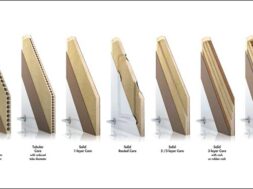

Challenges encountered during execution of project• Excavation in soft ground Both the portals of main tunnels (south and north portal) have been excavated in soft ground to a length of 650 metres and 600 metres, respectively. The overburden in this portion is less than 50 metres. Working in this soft ground was challenging as there is always a threat of loose material collapsing during the exaction. Hence the excavation was carried out segment wise. The top part is excavated first with a round length of 1-1.5 metres, which is subsequently treated with face and wall-sealing shotcrete.

• Restriction of blasting due to existence of villages over the alignment of tunnel From 308 metres onward, the ground conditions revealed a sudden characteristic change. The strata in this area comprised of salty clay infested with heavy boulder all along the tunnel section. Due to the presence of Cheril village (thickly populated area) above the alignment the excavation by drilling and blasting was totally avoided. On the contrary the boulders in the tunnel profile were broken by the breaker of the tunnel excavator. Considering the stability of the soil strata, the face was further divided into 8-9 sectors and the excavation was carried out accordingly. The face was treated with sealing shotcrete, wire mesh and face bolts alternately after each sector excavation. In order to further reduce the working vibration developed in the tunnel, the temporary invert is being drilled with 40-mm holes with a centre-to-centre distance of 200 mm.

• Excavation through heavy ingress of water As per hydrological and geotechnical interpretative report provided by IRCON, Pir Panjal Tunnel was expected to maximum seepage of (70 litres/sec). But during the execution, there was a heavy ingress of water flow (180 litres/sec) experienced from face, crown and wall portion. This propelled reduction in efficiency of each activity. The execution of work under heavy ingress of water is a challenging work.

• Casting of RCC invert lining The invert lining was carried out in rock class V, VII and VIII. The first 640 m comes under rock class VII and VIII; therefore the invert excavation was carried out between Ch 152+600 to 153+240, the permanent RCC invert lining also proposed in the portion. The lining of permanent invert was affecting other works due to restriction of vehicular movement. In order to tackle the above problem and to carry out the invert lining parallel to other main works, a cantilever invert bridge was introduced. The usage of invert bridge is the first time in India for tunnelling works. Due to introduction of invert bridge the lining work was carried out simultaneously without affecting excavation works.

• Survey works The surveying in such kind of underground tunnelling in Himalayan region is a big task. The Pir Panjal Tunnel is 10.96 km long tunnel in which the accuracy of tunnel alignment is a major concern to survey department. As per Railway requirement, the maximum permissible deviation in vertical and horizontal alignment is 10 mm/km and maximum 60 mm horizontal and vertical offsets are permissible during breakthrough of heading. Maintaining this accuracy level is not possible in conventional underground surveying in such kind of long tunnels. Therefore, the net survey technique was frequently used at regular intervals for maintaining the tunnel alignment in the specified accuracy. This is latest, most accurate surveying method in underground works. By following this survey method, the breakthrough of Pir Panjal Tunnel was achieved with zero error on heading portion. It is a big achievement in such kind of long tunnels.

• Work during winter The project site falls under the snowfall region of Jammu and Kashmir. The winter season starts in November and continued up to March. During the peak period of winter, the temperature reduces below 0 C and stays between -3 C and -10 C with frequent snow falls. The access roads to the project site sometimes get fully covered with snows.

• Logistics Another challenge was ensuring the comfortable working environment inside the tunnel and effective supply chain to the working locations. The supply of proper ventilation, communication, water supply, electric supply inside the tunnel is a major concern throughout the construction period for effective working and better progress. For ventilation, two independent ventilation systems were provided from both the faces. The system adopted for ventilation was forced fresh air ventilation system which provides fresh air directly to working face in the underground area. The return air would flow freely via the excavated area of tunnel to open portal/ADIT resulting in removal of all fumes and toxic gases.

Socio-economic impacts Opening of Banihal to Qazigund section of the Jammu-Srinagar-Udhampur railway line promises a new beginning for the state as it will significantly ease the transportation problem faced by the people during winters when inclement weather forces closure of the Jawahar Tunnel which is the sole link to the Kashmir Valley. In addition, it will considerably reduce the travel time between the two places. The distance between Banihal and Qazigund, which is also one of the most treacherous stretches in the entire Kashmir rail network, will reduce from 35 km by road to 17.5 km on train.

Dream projectPir Panjal Railway Tunnel, Jammu and Kashmir• Client: IRCON• Project Cost: ` 391 crore• Developer/Contractor: HCC (Zone IV and V)• USP: 100 per cent water proof and equipped with fire-fighting system• b: Commissioned on June 26, 2013

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.