Building Tower

A closer look on how tower cranes can provide an easy, economical and faster solution for high-rise building construction

As the cost of land is increasing sturdily, only way to provide economical housing solutions is by increasing the FAR (Floor Area Ratio), which in other terms means going vertical. With high-rise becoming the only solution for builders and developers the challenge to take the material up the building, which is difficult and laborious. Gone are the days when labour use to lift the building material on the top for construction.

It is a fact that without tower crane the construction of high-rise is impossible. The biggest advantage of utilising the tower crane is: it saves time, reduces number of labour, lifts heavy materials etc. Detailing on the advantages, Anil Mudgil, Vice President, Construction Equipment Division, Action Construction Equipment Ltd., says, “Tower cranes provide an easy, economical and faster solution to lift and place the material on top of the building. By using tower crane we save time, money and can avoid issue with managing large number of labour. Further, with tower crane concrete can be used to precisely place the concrete for columns and beams where concrete pump or material hoist may not be very effective. With use of tower crane over material hoist you can easily reduce the concrete wastage by 2 per cent.”

Tower crane used at DB Crown has a jib length of 45 metres and a freestanding vertical height of 52.50 metres. Given its size, the crane has the capacity to hold up to 10 tonnes at any given point in time. Explaining the tower cranes benefits and how cost efficient it is, Vipul Bansal, CEO, DB Realty, states, “The cranes used for construction of DB Crown are floor climbing tower cranes. This means that the crane is attached to steel beams that are resting in the RCC walls of the lift shaft. This means that the load distribution is less, making it stable mechanism. Given that it is within the lift shaft that is already constructed, we have the added benefit of saving space as another structure to hold the crane need not be constructed. An additional benefit to the floor-climbing crane is that is cost efficient. Since the crane is not bolted to the ground, there is no requirement for additional masts to be installed.”

Tower cranes are essential equipment in the present civil engineering especially in high-rise buildings. They also execute projects safely and well in time which really benefits the contractor or builder economically. As per Krishna Kumar, Divisional Head -Tower Cranes, Liebherr India Private Ltd, is a professional and economical solution for the construction industry, on this note, he says, “Shifting material like cement and steel etc., is always a challenge for high-rise buildings. So the only professional solution is, use of tower cranes from the beginning of the project, which is an economical solution for high-rise buildings as it saves manpower and reduce the project duration and also a safe method to shift materials at heights.”

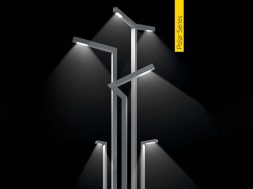

Dr. Vikram Mehta, Managing Director, Spartan Engineering Industries Pvt Ltd. says, “Spartan tower cranes are designed and manufactured as per EN 14439 standard. This European standard deals with all significant hazards, hazardous situations and events relevant to tower cranes.” Spartan Engineering, provides CAT HEAD tower cranes, which are CE standard design, with robust mast and jib section for uninterrupted and safe operations.

The real estate market is very competitive with several new projects vying for buyers attention. As pressure mounts on developers to bring projects to market quicker, coupled with the trend towards skyscrapers, the industry has witnessed shift in demand towards mechanisation in India’s real estate industry. In addition to being able to deliver quicker, using modern construction techniques such as tower cranes also add to the credibility of the project.

With the growth of skyscrapers, not only in metro but also in the two tires and three tier cities now tower cranes has evolved as a necessity. For working on high-rise projects, Zoomlion offers flat top cranes ranging from 4 to 25 tonnes, hammer head cranes ranging from 5 to 25 tonnes and Luffing Jib tower cranes ranging from 8 to 25 tonnes.

Tushar Mehendale, Managing Director, ElectroMech Material Handling Systems, mentions some of the tower cranes such as flat top, hammerhead, Luffing Jib tower cranes and its advantages in details. Flat top cranes are designed for safe and reliable performance while ensuring high cost-efficiency. These cranes are efficient, quick to erect and can self-dismantle and have low operational costs. The flat top design is most suited where multiple cranes are being used in close proximity. These cranes are available with spans up to 80 metres.

The cranes from the Hammer head series satisfy diverse construction requirements of different users. Safety devices, robust structure and specially developed PLC electronic control technology enable the tower cranes to be safer and more reliable. These cranes are available with spans up to 80 metres.

The technical parameters and performance of Luffing Jib tower cranes are ideal for special construction requirements. They feature large lifting capacity, small swing radius and require little operating room. Especially suitable for narrow spaces in urban areas and multiple tower project construction, they are the best choice for high-rise projects in crowded cities. These cranes are available with spans up to 60 metres.

A better substitute for labourTower cranes are the only solution in high-rise building for lifting materials, building elements. Since high-rises are becoming more popular not only in metros but also in tier 2 and tier 3 cities, the real estate and commercial property sectors will demand more tower cranes. There is certainly a large disparity in the demand for tower cranes from various regions as well as verticals.

The real estate construction sector alone generates 85–90 per cent of the total demand for tower cranes in India. Region-wise, North India accounts for 45 per cent of demand, Western India 30 per cent, South India 20 per cent and East India 5 per cent.

Mr Mehendale, explains what are the factors because of which tower cranes can be useful for the real estate players and how it can be applicable for rising trend and technology. He says, “The rising trend of precast technology for real estate construction is another factor that will drive demand for higher capacity tower cranes. Currently, the TC 5013, 5 MT hammer head tower crane is the most commonly used tower crane by this sector, accounting for close to 70 per cent of total volume. However, as precast technology becomes more common, higher capacity tower cranes, in the range of 8 – 20 tonne will be required. Another trend that has just made an entry into the Indian real estate construction sector is: tunnel slipform work. This technology requires higher capacity tower cranes capable of working at high speeds with utmost reliability.”

At the onset, it has to be acknowledged that a high-rise cannot be constructed without the use of a tower crane. At DB Crown, they are making use of a hammerhead crane to construct the 3 towers at Prabhadevi. Mr Bansal, finds that, application of tower cranes reduces the cost of labour and reduces the dependency. On this note, he says, “When constructing towers with a height of over 250 metres, it is considerably safer to utilise a tower crane as opposed to manpower as it is easier to lift the materials to the required slab without individuals having to navigate across a construction site, carrying heavy materials. The use of a tower crane also allows for the labour force to be utilised elsewhere as the tower crane reduces the dependency on manpower by approximately 40 to 50 per cent. This in turn also benefits the project as it makes it far more cost effective; your initial investment is high but the cost of labour is reduced as well as the time taken for construction.”

While detailing on the areas of applications, Mr Mudgil, said, “The Tower crane can be used for various applications like housing projects, factories, malls, power plants, hydro electric projects, infra projects like bridges, constructions of piers, metro and rail stations, overhead water tanks. These machines are being extensively used in all high-rise projects for casting or pouring concrete in columns, beams as well as slabs apart from handling all building material like steel, cement, bricks, tiles, scaffolding, shuttering, sanitary fitments.”

Similarly, Mr Kumar, believes, “The tower cranes are used not only for completing the building structure but also using for lifting the MEP materials, like chillers, interiors, plumbing fittings.”

Overall the use of tower cranes can be useful for many sectors as mentioned above and with the advanced technology the demand for tower cranes will also increase.

Playing it safe Safety is of prime importance with respect to installation, operation, height increase or decrease etc, of a tower crane. This is a very important aspect of tower crane usage as otherwise it can lead to major accidents. To avoid such accidents, proper training and care should be taken.

Tower cranes cannot be operated without utmost care. The cranes themselves have in-built safety features, such as a ‘Limit Switch’ that will automatically shut down the crane’s operations if the load exceeds the stated capacity and sound an alarm. They also have ‘Anti-Collision Sensors’ as another in-built feature, so that there is no possibility of two cranes intercepting the other’s area, causing a collision on site. Additionally, considering the height most high-rises are reaching today, interception of the flight path is a factor that needs consideration, for this reason the tower crane also consists of an aviation light at the highest point.

It is the responsibility of every manufacturer and a developer to maintain the cranes in a proper condition. Mr Bansal, opines, “As a developer, the safety measures that we put in place are vital, yet simple. The tower cranes go through weekly maintenance to ensure that they are in prime condition, therefore limiting any potential safety hazards. Additionally, only licensed operators are allowed to operate the tower cranes.”

It is necessary to select the suitable and correct crane size required for the project requirement and always many factors are to be taken in consideration while determining the tower crane for high-rise buildings. Mr Kumar, recommends, “It is always recommended to have prior discussions with the with tower crane supplier to determine the correct model of the crane and which suites to projects. As Liebherr has “Tower crane solutions” and the experts from the department submit an economical solution with a complete project proposal, this helps the customers to execute the project safely and timely.”

Action Construction Equipment provides important safety features in tower cranes like limit switches for trolley, hoisting, slew functions, overload and moment limiters with alarm and cut off in case of unsafe or overload operations. They also offer Safe Load Indicators (SLI) along with automatic cut off, anti-collision device for projects where 2 or more tower cranes are working in close proximity of other tower cranes or buildings and other such advanced safety devices optionally as and when required by customers.

Proper training and under proper guidance for the operation of tower crane is must. On this, Mr Mudgil, has a different outlook, he says, “Our engineers and technicians have been trained adequately to ensure proper working and calibration of these safety devices and as a practice we try and check the completeness and proper working of these devices on every visit to the machine site. We feel that the most important factor toward safe operation is a good and trained operator. Precisely because of this reason only we have started a well-equipped training centre at Faridabad to provide operation and maintenance training to our customer’s personnel.”

From the safety points of view, Dr Mehta, suggested the points to be considered while selecting a tower crane for high-rise building. He mentioned, “One should opt for jerk less safe operation, safe wire connection, clear vision through glass in all weather condition.”

On the other hand, ElectroMech offers ZEPL range of tower cranes incorporate several innovative features that ensure safety, ease of operations and maintenance. These include:• A parameter monitoring system that ensures all movements remain within the safe programmed limits.• Self-climbing mechanism with anti-drop device for safe jacking operation.• Climbing frame with platform for easy and quick self-erection.• Limit switches for hoisting, slewing and trolley movement.• Anti-twist device for wire rope.• Trolley with safety features such as wire rope breakage protection, axle breakage protection and wire rope guide.• Load limiter as well as moment limiter provided to ensure safe operations.• Anemometer and lightning arrester to prevent mishaps due to environmental conditions.• Quick change device for switching between wire rope falls. This enables handling of heavier loads at low speeds and lighter loads at high speeds with the same crane, thus enhancing productivity at the construction site.• Modular connections of the counter jib and main jib to the slewing module ensure quick assembly and disassembly, saving time and effort.• Ladder with safety cage and rest platforms for convenience of operators and maintenance personnel.

Mr Mehendale’s view also matches to the experts in terms of safety measures while operating tower crane. He feels, “We regularly conduct operator training to ensure the cranes are always operated safely. Moreover, operators are given specific training on visual inspections as well as regular preventive maintenance activities to be performed on the cranes on a daily, weekly and monthly basis. Adherence to this ensures that no untoward incidents take place with regards to the crane.”

ConclusionIn the coming years, the high-rise trend will be much more ahead and there will be many changes in the technology and the equipment use. Tower cranes is one such technology that has reduced stressful work, but at the same time is very critical to operate. Hopefully, the construction industry in India will see advanced tower cranes with proper skilled and licensed operators that will lead to faster construction and save time and lifting building material will no more be a challenge. __________________________________The tower cranes go through weekly maintenance to ensure that they are in prime condition, therefore limiting any potential safety hazards. Vipul Bansal, CEO, DB Realty.______________________________________

We regularly conduct operator training to ensure the cranes are always operated safely. Tushar Mehendale, Managing Director, ElectroMech Material Handling Systems______________________________________

One should opt for jerk less safe operation, safe wire connection, clear vision through glass in all weather condition.Dr. Vikram Mehta, Managing Director, Spartan Engineering Industries Pvt ltd.____________________________________

By using tower crane we save time, money and can avoid issue with managing large number of labour.Anil Mudgil, Vice President, Construction Equipment Division, Action Construction Equipment Ltd._______________________________________

The tower cranes are used not only for completing the building structure but also using for lifting the MEP materials, like chillers, interiors, plumbing fittings.

Krishna Kumar, Divisional Head -Tower Cranes, Liebherr India Private Limited

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.