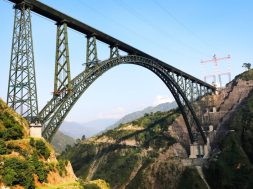

Conquering great heights with secure scaffolding

The increasing demand for infrastructure development in the country is creating more demand and opportunities for the scaffolding companies. Rakesh Modi, Chairman, Mtandt Group, talks about the significance of scaffolding in the construction industry.

How is scaffolding changing the construction behaviour in the industry?

The boom in commercial real estate had lead to development of malls, offices, hotels, hospitals, educational institutions, multiplexes, airports, metros, railway stations etc. This has augmented the use of aluminium scaffolding systems. It is being increasingly used to clean roofs, facades and windows, painting jobs, electrical cable installation work, air condition ducting, watchtowers etc.

Aluminium scaffolding systems are one of the most economic and cost effective solutions to reach and work safely at heights. It is also the most versatile because of its modular nature which enables quick assembling and dismantling. They can be customised to suit specific requirements across a variety of surfaces and situations. They can be utilised safely on staircases and escalators, too.

How can the scaffolding structures be made safer and the risk of accidents reduced?

Mtandt’s Aardwolf Quickfit aluminium scaffolding systems have a stable platform, a stairway to climb along with handrails. On the platform, we have guard rail frames. For additional safety, we have triangular stabilisers in all four corners of the H frame. They are fitted with all terrain effective locking nylon wheels with PU outer ring to ensure load distribution. While the toe boards on sides of the platform provide extra safety and prevent small tools or tackles from falling, the long weld less spigot provides for more strength and ensures long life and safety of the structure. The weld less stainless steel articulation improves the scaffold’s rigidity and increases its strength. The stairway with antiskid tape provides better foot grip. Aardwolf Quickfit systems have the inbuilt feature for safe ascent and descent and designed platforms with safe trapdoor or hinged entry and exit as per the application. Mtandt Aluminium Scaffolding Systems are very safe and conform to EN 1004 European standards.

According to you, what are the drivers of demand in scaffolding and formwork segment?

When shifting for maintenance and fitment works in different areas within the same premises, it’s imperative to find a material that is light in weight and easily moveable. Aluminium scaffolding provides effortless set up or erection as compared to other heavier scaffolding materials that are more strenuous to install and require more time. The height can be increased or reduced with modular components as per the nature of work. Aluminium scaffolds require very less maintenance as they don’t have moving parts beside wheels. You may have heard of the expression, “Time is money.” Hence, any kind of equipment change or shifting which means faster work, while not compromising on safety, is a winner. This is why there are more and more providers of aluminum scaffolds because they know that the industry is moving in this direction and Mtandt is a pioneer in this segment.

Aluminium scaffolding systems are one of the most economic and cost effective solutions to reach and work safely at heights.

Rakesh Modi,

Chairman, Mtandt Group

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.