Manufacturing companies in India are leveraging green chemistry in the manufacturing process which proves to be less harmful for the environment.

Every other day the world witnesses a sad calamity, with every passing minute we move a step closer to global warming. As per a study by IQAir AirVisual and Greenpeace, 7 of the world’s 10 most polluted cities are in India. The biggest sources of pollution are generally household emissions, industrial emissions and transport. We need year-round measures on a national scale, like cleaner fuels for motorised transport, removing subsidies on dirty fuels, enforcing strict controls on open waste burning and reducing industrial emissions. Authorities aim to make a green shift in manufacturing to reduce air pollution and move towards sustainable development. The reason to consider manufacturing solely is because that’s where we can make an eco-friendly shift from scratch.

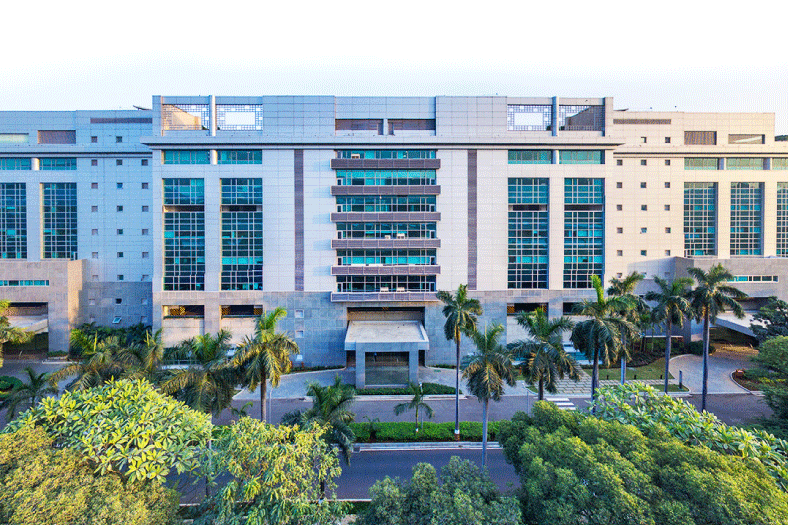

Manufacturing companies in India are leveraging green chemistry in the manufacturing process which proves to be less harmful for the environment. For instance, at Godrej Locks’ eco-friendly manufacturing unit in Goa, we have adopted the technique of Green Chemistry for manufacturing locks. A process for ion exchange has been installed for selective heavy metal removal, making it extremely energy efficient. It also has an online automated effluent treatment plant. Eco-hazard materials have been replaced with more bio-sensitive alternatives. The green chemistry technique utilizes trivalent chrome, which is non-cyanide based, instead of environmentally hazardous hexavalent chromium. Similarly, alkaline copper system is utilized in the plating process rather than the hazardous cyanide copper. Most of the materials that are used are recycled (brass, Mazak, etc). The processed scrap is sent back to the smelter to convert into raw material again for further use. Despite the cost of eco-friendly procedures being comparatively higher than the standard procedures, manufacturers must adopt them due to positive long term impact on both the environment as well as the business.

Government should encourage corporates to manufacture eco-friendly products and supporting policies to make the necessary raw materials cheaper. This will also inspire corporates to make a behavioral shift towards making the manufacturing processes carbon neutral.

Training towards green manufacturing can help develop research and utilize technologies and practices to lessen the impact on the environment. This would include technologies such as increased use of Renewable energy sources within the establishment, reducing waste by using raw materials more efficiently, waste management monitoring before sending it to the landfills, reduce, reuse, recycle and renew all the waste generated. Having a water treatment plant for manufacturing units and using more sustainable and biodegradable material should also be brought in practice

These practices must be followed by all manufacturers, big and small. Manufacturers can incorporate small changes while they proceed towards more environment friendly means. It could be made mandatory for companies that fall under a certain revenue bar. Such practices need to be implemented effectively and willingly on an individual level by manufacturers and change will be visible as we move ahead.

Authored by:

Shyam Motwani

EVP & Business Head

Godrej Locking Solutions & Systems

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.