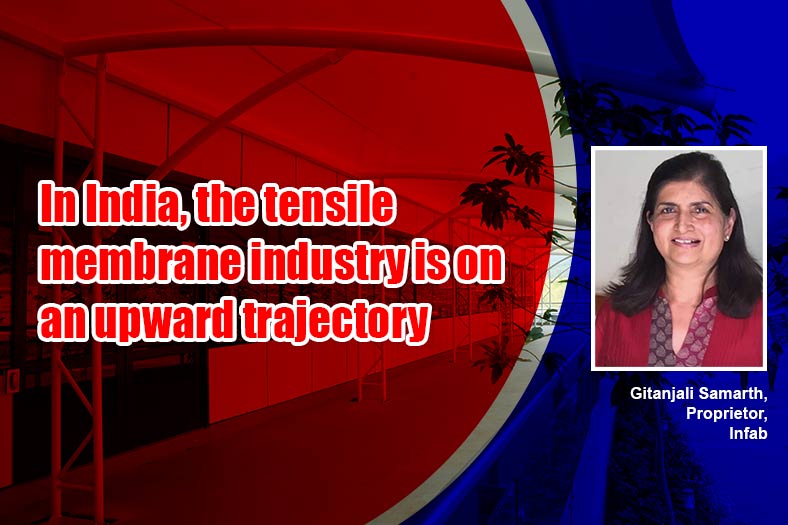

In India, the tensile membrane industry is on an upward trajectory

They are visible in sport stadiums, airports, shopping malls, office buildings, terraces. In the coming months & years this visibility is only going to increase says Gitanjali Samarth, Proprietor, Infab.

What are the current trends and innovations in the tensile membrane Structures?

Tensioned membrane structures are considered the 5th construction element after concrete, metal, stone and glass. Its popularity is growing and it is being adopted as a leading solution to many of today’s biggest design challenges. There are exciting & new things happening in this field.

People are looking for structures with life expectancy of 25 + years even up to 40 years. The traditional PVC & PVDF fabrics have made way for PTFE coated fabrics which can provide this.

The trend is towards creativity and incorporating art and aesthetics into designing. Working in tandem with landscape designers, architects and city planners, is moving tensile membrane structures to the next level.

Increasing energy efficiency, cutting electricity costs, reducing carbon foot prints is another important factor that is driving the innovative trends in this field. The trend is towards providing cost –effective solutions such as tensile membrane Facades for reducing solar heat gain and fabric structures with strategic water control for conservation initiatives.

As the awareness, usability and applications of tensile membrane structures is increasing, so is the demand. Therefore, there are more and newer players jumping into the fry leading to price wars. Although this is a good thing, the down side of it is that at times quality can get compromised at the altar of competitiveness. This is a trend that is visible in countries such as India and can at times be counter productive

How do Tensile membrane structures prove to be cost effective solutions for the Indian construction market?

In India, there is an increasing trend towards moving away from traditional brick and mortar structures. The indisputable advantage of light weight tensile structures lies in the minimum weight of material used. At less than one fourth the weight of comparable structures employing glass/polycarbonate sheets, not only are fabric membrane structures lighter but the amount of material required and the silhouette of the support structure is minimized thereby reducing the overall cost of a project substantially.

Due to high level of prefabrication at the production level, cost efficiency is also achieved due to the speed in erecting such structures. Furthermore, transportation, disassembly, reuse & recycling is accomplished in an easier way as compared to traditional methods.

As far as utility of tensile membrane structures are concerned, what are the limitations & challenges?

The biggest limitation of using architectural membranes is the low thermal insulation as compared to classic building materials such as concrete, wooden slats, shingles etc. Large amount of heat from solar radiation penetrates through the membrane causing overheating especially in summer. This is a major challenge especially in a country such as ours as it substantially adds to air conditioning costs and restricts the usability of such structures.

What is your outlook for the tensile membrane industry in the year 2020?

The aesthetics, importance and usability of tensile membrane structures cannot be undermined. They are the structures of today and of the future. In India, the tensile membrane industry is on an upward trajectory. They are visible in sport stadiums, airports, shopping malls, office buildings, terraces. In the coming months & years this visibility is only going to increase simply because not only are they cost effective, functional and can span large areas without intermediate supports but also because of the sheer beauty and versatility of creating designs& shapes. There is no getting away from the fact you will see more and more of these in time to come.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.