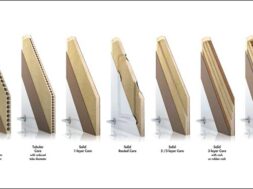

Kamachi: adding strength to Indian steel sectorKamachi Group has begun its journey in 1978 and risen to a competitive business conglomerate as well as one of the market leaders in the steel sector of India. Today, the Kamachi Group has made its mark in establishing various business units in a wide spectrum of industries, encompassing steel manufacturing and processing, energy, imports and exports. Its product Kamachi TMT bars, which is South India’s one of fastest growing TMT brands, come from South India’s first integrated steel plant dedicated for TMT.This new generation steel has proved its mettle with returning customers like L&T, DLF, National Highways Authority of India (NHAI), Wipro, Godrej and almost all leading construction companies. Casa Grande, TVH, Unitech, Hiranandani, Purvankara, B.L. Kashyap, CCCL, IVRCL, Landmark, Olympia, Golden Homes, Ozone Group, Real Value Homes, Jain Housing, Sobha Developers, Sugal & Damani, Amarprakash and Prince Foundations are some of its clients. This speaks about its quality and services for itself.The product is a result of a series of processes. The manufacturing process involves billets which are rolled into rebars and then passed through a thermo mechanical treatment (TMT) process. At Kamachi TMT, these billets which are made from virgin iron, pass through the most advanced German rolling technology and are treated in the TMT process patented by Thermex. The unit is fully automated and DCS automation to ensure that every bar is tested and completely back tracked. With a monthly 40,000-metric-tonne production capacity and a dealer network of over 500, Kamachi TMT bars are always within reach. The surface finish of the bars, the core formation and ductility can be matched with the best in the country. Most important, the consistency of its products can be tested on each and every bar. For perspective, it has the capacity to produce over 5 crore pieces a year.The state-of-the-art rolling mill is completely built at 5-metre height above ground level, giving it a competitive edge with better cooling efficiency, better working environmental and greater quality control over the product. It also features a unique slit technology, allowing the product of three bars at a time. This can be achieved only if the raw material is of the highest quality.The company manufactures grades ranging from Fe500, Fe500D, Fe550 and CRS (Corrosion Resistant Steel) with sizes from 8 mm to 56 mm and lengths up to 25 metres. This flexibility in product range coupled with ready-made steel features not only saves cost, but enables speedy construction.Its marketing campaigns have helped in better brand reach through bus backs, hoardings, wall paintings, multiple sponsorships and brandings at railway stations across South India. The company is committed to active environment conservation and has planted over 10,000 trees at the factory. In addition, Kamachi is committed to creating a forest cover of over 25,000 trees in association with grow-trees.com (tree planting partner of Billion Tree Campaign by the United Nations).

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.