Featuring the intelligent features of today’s advanced wheel loaders

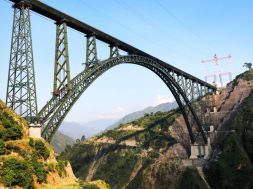

Volvo CE’s prototype autonomous wheel loader and articulated hauler

Over the years, Wheel Loaders have become integral part in construction due to their ‘value for money’. However, today technological advancements in Wheel Loader designing are happening especially in the direction of achieving increased power, reduced downtime, better fuel economy, operator comfort, and ease of operation and maintenance.

For example, powered by the Cat C7.1 ACERT engine, Caterpillar’s 950L wheel loaders feature greater productivity, lower fuel consumption, operator efficiency improvements and Cat Connect features. The 950L delivers considerable additional customer value including a new operator environment layout, new transmission with lock-up clutch torque converter (fuel efficiency and speed on grade) and new optional traction aids.

“The Cat 950L wheel loaders are designed to improve operator comfort, performance, and productivity,” claims Andy Dhanaraj, Sales Director, Global Construction and Infrastructure, Caterpillar India. “The unmatched, revolutionary world-class cab creates a comfortable, efficient, safe, and productive operator environment. The innovative Cat C7.1 ACERT engine is optimised for maximum fuel efficiency and increased power density. The Performance Series buckets are easy to load, improve material retention, enhance visibility and decrease cycle times.”

Construction equipment manufacturing major JCB recently launched a 5.5-tonne payload Wheel Loader – The JCB 455ZX. “This new addition in JCB India’s world-class Wheel Loader portfolio is fitted with a Common Rail JCB DieselMAX 672 engine and is targeted towards sectors such as mining, construction, ports, and roads,” informed Jasmeet Singh, Head – Corporate Communications and External Relations, JCB India Ltd.

Volvo CE, an innovator in the field of construction equipment, offers 11 wheel loaders for sale in India that are specialised at the larger end of the scale. “Our smallest machine is the L60F which has a static tipping load of 7,150 kg while the largest machine we offer in India is the L350F having static tipping load of 34,780 kg,” explained Dimitrov Krishnan, Vice President and Head of Volvo CE India.

SDLG currently offers the 3-tonne LG936 and 5-tonne LG958 wheel loaders in India. The Chinese major is all set to introduce the L933 – an addition to its line of 3-tonne loaders in December at Bauma Conexpo India 2016.

Intelligent features

JCB 455ZX Wheel Loader – the ‘Made in India’ product is designed to work more for longer hours at a lower maintenance cost, claims Jasmeet. He adds, “The world-class aggregates used in the machine ensure quality, reliability and value for money. With air-conditioning as standard, the 455ZX offers the best-in-class operator comfort. The large cabin interior offers excellent entrance. The stylish, modern central dash display combines analogue dials and a colour LCD screen that displays the health status of the machine, service requirements and operating information.”

The limited slip differential in the JCB 455ZX is ideal for working in demanding conditions. The Z-bar loader geometry facilitates enhanced penetration into the pile, as well as delivering high breakout forces, good roll-back angles and faster cycle time. In addition, the Electronic Management System allows for a progressive clutch cut-off giving effective loader control while the powerful twin variable displacement piston pumps enhance multi-function capabilities.

“Wheel Loaders from Volvo CE are recognised as some of the most advanced in the world, offering productivity and ROI levels not seen elsewhere,” claims Dimitrov. He adds, “Technology plays an important part – from the load-sensing hydraulics which are perfectly matched to the fuel efficient engine to the ergonomic Volvo Care Cab with leading levels of comfort and visibility, to the Volvo Contronic Monitoring System for closer monitoring of operation and performance.”

Of late, Volvo Construction Equipment demonstrated its prototype autonomous wheel loader and articulated hauler working together at the company’s Xploration Forum in Eskilstuna, Sweden. The prototype wheel loader filled the prototype articulated hauler – before dumping its load and repeating the cycle. “In a one-hour comparison it was found that the autonomous wheel loader could reach the equivalent of 70 per cent of that of a skilled operator’s productivity levels when loading and unloading. This is not just theoretical – the machine has also done ‘real work’ for a Volvo CE customer at an asphalt plant in Sweden,” a statement issued by Volvo Construction Equipment said.

“The demonstration machines were programmed to work together and carry out a specific set of actions on a pre-defined route,” explained Jenny Elfsberg, Director of Emerging Technologies at Volvo CE. “The machines can perform the same task over and over again, along a fixed route, for a relatively long period of time. But it’s still early days for this technology, we are working on developing solutions that have the required safety and performance levels that the market will accept.”

The new L933 wheel loader from SDLG is ideal for handling ready-mix concrete, or applications such as road building and quarrying, said Sanu George, Business Head, India, SDLG. “We are expecting a lot of interest in the new loader and grader.”

The new Cat L Series Medium Wheel Loaders have an ACERT engine equipped with a combination of proven electronic, fuel and air components. Applying proven technologies systematically and strategically lets us meet our customers’ high expectations for productivity, fuel efficiency, reliability and service life. Deep system integration results in reduced emissions, improved performance and improved fuel economy. The reliability, durability, and versatility of all L Series Wheel Loaders result in machines that are better built to meet customer’s needs. The new Cat Production Measurement app (integrated payload scale) option is integrated in the new touch screen display providing payload information.

Dhanaraj highlights some of the major outcomes of integrating advanced features in Caterpillar’s 950L wheel loaders which include:

• Lower operating costs: Deep system integration has improved component efficiency (e.g. split oil flow in the transmission) and some new features below improve productivity and save fuel resulting in up to 10 per cent lower fuel consumption compared to H-Series.

• New 5 speed transmission: 5-Speed powershift transmission with torque converter lockup, single clutch speed shifts and torque based down shifts reduce cycle time and improve loading and carrying efficiency. Combined with the new axle reduction ratios, it carries 21 per cent less torque and provides the same durability as the H-Series planetary transmission.

• Application performance: The new L-Series MWLs provide improved performance in a variety of common wheel loader applications. Faster accelerations and increased rimpull give the machine improved performance in Load and Carry and excellent bucket loading ability. The optional automatic front and rear disc type differential locks do not require any intervention by operators to engage or disengage allowing them to focus on the job at hand without losing productivity nor fuel efficiency in poor underfoot conditions.

• Operator efficiency: The new operator cab and environment with standard rear view camera, increased glass surfaces and new indicator and button layout greatly improve the productivity and safety of the operator all day long. The optional Cat Production Measurement app (integrated scale and cycle counter) is integrated into the secondary touch screen display; it provides an intuitive interface for production and payload tracking on board.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.