MACONS: constructing construction equipment

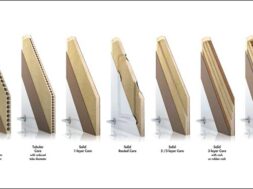

MACONS provides a complete range of solution in the form of construction equipment. Focused on research and development, the company continuously expand and upgrade its products and services. The journey so far makes MACONS feel proud, and the plans for the future gives it the energy to show the best. MACONS wet mix plants are manufactured with best of the components and accessories. The unique design features makes it most efficient in terms of operational costs and ensures close control of the quality of output. Available in fixed or variable speed drives, the plant is well equipped with adjustable gates at its bins. The design of twin-shaft pug mill ensures fast, continuous, and homogenous mixing of aggregates and additives. Besides, the surge hopper arrangement allows discharge into trucks without shut down and spillage. These plants are application-designed products built as per MOST specification for achieving homogeneous mix material of WMM/CTAB/GSB layer to prepare sub base or base in road projects. DescriptionThe major parts of the plant comprising:• Four bin feeder• Mixer unit-pug mill• Load-out conveyor• Storage silo• Controls and automation.

Four bin feederThe bins are modular which facilitates addition of bins to meet up the growing needs. The bins are integrated with adjustable gates. The variable or fixed drives can be supplied for the belt feeders. The optional variable speed drives coupled with controls. Pug mill unitThe unit incorporates a proven design for fast, continuous and homogeneous mixing of aggregates and additives. The pug mill is designed vibration free with other trouble-free functions and longer life. The shafts are mounted on additional heavy-duty, anti-friction bearings. The paddle arm and tips are made from wear-resistant alloy steel resulting longer life. The paddle arm tips are reversible resulting lower maintenance cost. The liner plates are corrosion and abrasion resistant.Load out conveyorConveyor system consists of rigid frame fabricated from MS tubular section, rubber belt, idler and returns placed adequately and arrangements comprising of AC motor and gear box.Storage siloThe 25-tonne storage silo is robust and expedient and easy to shift and erect. Hydraulically operated gates open faster, resulting quick discharge of mix material into the trucks without any kind of segregation.Controls and automationThe automated control panel provides smooth operation of the different drives and a very preciously control of all processes. A control panel with necessary controls, push buttons, meters and electronic display of aggregate tonnes/hour and water in LPM located near to pug mill unit provides additional safety. The control panel cabin is fully weather protected and very familiar to use, and its design is suitable for industrial automation.Salient features• Modern wet mix technology.• Designed for domestic and international markets.• Modular design for containerised transport.• Portable or stationery.• Easy to operate.• Highly accurate aggregate feeders.• Fully automatic computerised control panel board.• Electronic weighment system with load cell.• An electronic water flow meter with sensor unit.• A monoblock water pump

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.