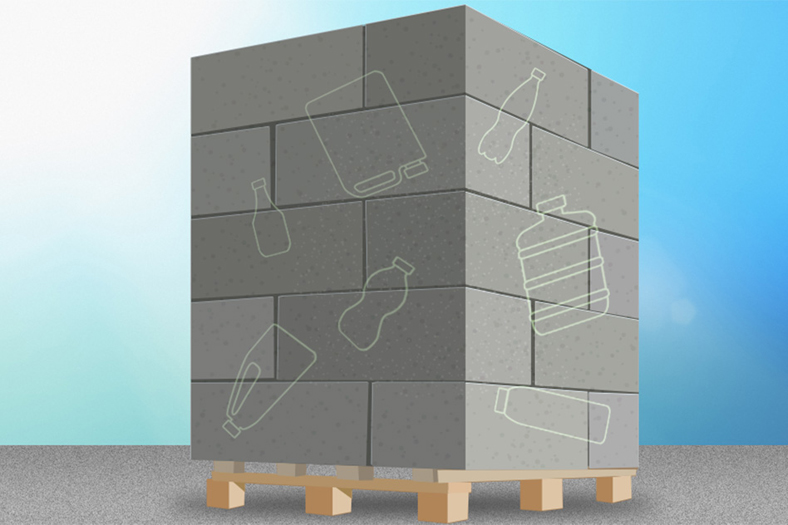

“Make concrete 20% stronger by adding recycled plastic”

Adding bits of irradiated plastic water bottles could cut cement industry’s carbon emissions, reveals MIT Study

Discarded plastic bottles could one day be used to build stronger, more flexible concrete structures, from sidewalks and street barriers, to buildings and bridges, according to a new study.

A team of MIT undergraduate students has found that, by exposing plastic flakes to small, harmless doses of gamma radiation, then pulverising the flakes into a fine powder, they can mix the plastic with cement paste to produce concrete that is up to 20 per cent stronger than conventional concrete.

Concrete is, after water, the second most widely used material on the planet. The manufacturing of concrete generates about 4.5 per cent of the world’s human-induced carbon dioxide emissions. Replacing even a small portion of concrete with irradiated plastic could thus help reduce the cement industry’s global carbon footprint.

Reusing plastics as concrete additives could also redirect old water and soda bottles, the bulk of which would otherwise end up in a landfill.

“There is a huge amount of plastic that is landfilled every year,” says Michael Short, an assistant professor in MIT’s Department of Nuclear Science and Engineering. “Our technology takes plastic out of the landfill, locks it up in concrete, and also uses less cement to make the concrete, which makes fewer carbon dioxide emissions. This has the potential to pull plastic landfill waste out of the landfill and into buildings, where it could actually help to make them stronger.”

The study observes that concrete with fly ash or silica fume was stronger than concrete made with just Portland cement. And the presence of irradiated plastic strengthened the concrete even further, increasing its strength by up to 20 per cent compared with samples made just with Portland cement, particularly in samples with high-dose irradiated plastic.

The concrete road ahead

After the compression tests, the researchers went one step further, using various imaging techniques to examine the samples for clues as to why irradiated plastic yielded stronger concrete.

The team took their samples to Argonne National Laboratory and the Center for Materials Science and Engineering (CMSE) at MIT, where they analysed them using X-ray diffraction, backscattered electron microscopy, and X-ray microtomography. The high-resolution images revealed that samples containing irradiated plastic, particularly at high doses, exhibited crystalline structures with more cross-linking, or molecular connections. In these samples, the crystalline structure also seemed to block pores within concrete, making the samples more dense and therefore stronger.

“At a nano-level, this irradiated plastic affects the crystallinity of concrete,” Kupwade-Patil, a research scientist in the Department of Civil and Environmental Engineering says. “The irradiated plastic has some reactivity, and when it mixes with Portland cement and fly ash, all three together give the magic formula, and you get stronger concrete.”

“We have observed that within the parameters of our test program, the higher the irradiated dose, the higher the strength of concrete, so further research is needed to tailor the mixture and optimise the process with irradiation for the most effective results,” Kupwade-Patil says. “The method has the potential to achieve sustainable solutions with improved performance for both structural and nonstructural applications.”

Going forward, the team is planning to experiment with different types of plastics, along with various doses of gamma radiation, to determine their effects on concrete. For now, they have found that substituting about 1.5 per cent of concrete with irradiated plastic can significantly improve its strength. While that may seem like a small fraction, Implemented on a global scale, replacing even that amount of concrete could have a significant impact.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.