Making of Vienna Central Railway Station with Tekla and Trimble

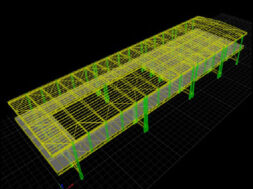

35 experts from Unger Steel Group utilised Tekla’s BIM software in a very advanced way to plan, produce and assemble the diamond trusses of the partially transparent, architecturally stunning roof of the new Vienna Central Railway Station

The project The new Vienna Central Railway Station is a major European traffic hub – when completed, about 145,000 passengers and 1,000 trains will pass through the station every day – and development project with attached shopping mall, residential buildings and park. Unger Steel Group had to work with precision on crowded site and take the other project parties into account.

Unger was contracted to complete the roof which covers the tracks, with the complex geometry of the 14 unique diamond-shaped steel trusses. The company used Trimble Total Station with Tekla software for the job.

The model Tekla created constructable steel structures, modelled and detailed the main structure and substructures like cable channels, and extracted data and drawings for production and assembly, simulated welding sequences of the complex components.

Up to ten designers worked on the model in multi-user mode. Unger imported the architects’ model as 3D DWG files to Tekla Structures for designing and detailing the diamond trusses. As numerous project parties operated on the huge construction site, Unger included also platforms with rails and concrete foundations to the model in order to notice and solve possible clashes already in the design phase.

BIM EverywhereAt Unger BIM does not stop to the design office door. The company configures each new version of Tekla Structures according to their standards, which enables them to plan specifically for their cutting and production machines.

For the Vienna Central Station, Unger created all transport lists and surveys directly from the model in Tekla and used it to control production and assembly sequence.

Automating production For production at Unger’s workshop, the required data is transferred directly from design office to DSTV and interfaces with the cutting machines in workshop. Therefore production can start immediately after completion of planning. Transferring fabrication information automatically to production machinery means errors are avoided.

Punctual logistics Unger chose Tekla for planning transportation lists because they had to work punctually, timing and having the right material at the right place. Unger’s team had to assemble the complex diamond trusses in a very limited space which also contributed to the logistical challenges. The individual pieces arrived to the site just before the staff bolted them together. The site staff assembled the first diamonds on Vienna Central Station while workshop team produced the remaining ones. The entire process from cutting one truss to its final assembly took on average three and a half months.

Positioning with Trimble Total Station Unger Steel used Trimble Total Station with Tekla for assembling the diamond trusses. Unger assembled the roof components while these hung from a crane, and the team needed exact position information for lifting and fitting the components correctly at 15 metres above the platforms. A combination of Tekla and Trimble was utilised in a preassembly workshop to measure the components after welding to spot possible manufacturing tolerances before assembly, and later to control the position of the structure and put the parts together.

From Total Station to Tekla and back The workflow of positioning the roof parts moved in rounds. Unger’s team measured the structure with Trimble Total Station, imported the data to Tekla Structures, adjusted it, and exported the modified data back to Total Station for positioning. As any inaccuracies would have affected the composition, the Unger team performed control measurements continuously in case the components would carry tolerances from fabrication or transport. On the connection points of the diamond trusses, the team measured the structure, downloaded the measurements into the Tekla model and after this planned and manufactured the connection parts. On site, they also marked building axes with Trimble Total Station.

Time, Money and Workflow Smooth workflow between office and site is the goal of every construction company, and according to Unger, Trimble and Tekla together take their customers closer to this goal. BIM and automated data transfer accelerated the project. With Trimble Total Station, Unger’s own staff could measure the structures to save on expenses of external surveyors. And as they transferred the measurements of the built structure directly to Tekla, they saved time and labour because they did not have to enter the measuring data manually. Tekla eased the logistical challenge with automatically generated transport lists and aid in controlling production and assembly sequence.

Collaboration using Tekla BIMsight Unger chose Tekla BIMsight for collaboration with project parties like architects and structural engineers. The main benefit was that each project party had the building information model available and could work together – including production and installation teams on site. Unger also utilised Tekla BIM sight for approval process in the planning phase. _________________________________

Benefits of Tekla? We had the necessary information centralised to the model and available for sharing, production, installation and billing – quickly and with the right quality.

– Erich Fladerer, Unger Steel Group

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.