Simplifying life with Tiscon Readybuild: spreading re-bar downstream services across India

With a rich history of over 100 years, Tata Steel has been always proud of being a pioneer and innovator. Having worked continuously to strengthen products and processes alike, Tata Steel is the first steel company outside Japan to have won the coveted Deming Prize for quality. The long products division that produces Tata Tiscon re-bars has been proactive in bringing innovation to the market and giving much needed solutions to customers. Long Products has always been the first to tap into the needs of customers — be it the establishment of retail channels to reach the individual home builders in every nook and corner of the country to developing new products like the 7-mm re-bar and the Fe 600 re-bar for reputed institutional players such as L&T and Gammon. Tata Tiscon is also the first super brand in its category.

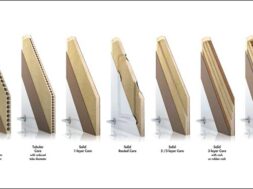

Tiscon Readybuild: downstream re-bar brand from Tata TisconTiscon Readybuild is the latest innovation in Long Products from Tata Tiscon. Readybuild aims at reaching closer to the consumption pattern of re-bars. More than 90 per cent of re-bars consumed are for cutting and/or bending purposes (at the usually supplied length of 12 metres). This activity of cutting and bending the re-bar in the desired shape has traditionally happened in an inefficient manner through manual labour on-site. Readybuild provides the cutting and bending solution to the customers and facilitates the ready-to-use material supply. India has been growing rapidly with infrastructure, and construction sectors are growing at a very healthy rate.

The sustenance of this growth poses issues of skilled labour availability which further effects the timely completion of projects. Also, the cut and bend structures required in construction often use re-bars of different size and shapes. For the same, the construction companies have to maintain inventories of all the required SKUs.

Readybuild aims at reducing the extra inventory cost borne by the construction companies. Also, unavailability of even a single SKU may result in a delay of the project. With Readybuild, the construction companies have no need to worry about the availability of SKUs needed in the cut and bend structure. Furthermore, Tiscon Readybuild provides the reliability of quality steel and better site productivity due to reduced involvement of labour and reduced wastage. Overall, the use of Readybuild facilitates timely completion of projects, leading to a better working capital management and revenue realisation for the construction companies. All in all, Tiscon Readybuild aims at simplifying the lives of all concerned stakeholders.

Availability: primary need of any serviceTiscon Readybuild started its production with bar fabrication centres in Bangalore and Faridabad. However, to support the large construction growth and reach the customers across the country, it was imperative to open up centres in other major consumption zones. Tata Steel has, hence, started new Readybuild centres in Ahmedabad, Secunderabad, Mumbai, Kolkata and Kanpur with further plans of expansion in other major cities. Each of these centres is equipped with shearing and bending machines that can produce a varied range of re-bar shape requirements for construction purposes. These centres can produce a simple re-bar of a specific length to complicated 3D re-bar designs like spiral shapes and can cater to a demand of up to 3,000 tonnes per month.

Mumbai and Delhi, owing to being higher demand points, have two Readybuild centres. These centres give an OTIF (On-Time-In-Full) delivery service that works like clockwork to meet cut and bend needs in compliance with the clients’ working schedule.

The bar fabrication shop is designed and supported by the technology used in the cut and bend service offered by NatSteel, a wholly owned subsidiary of Tata Steel.

After-sales team: delivering beyond sales Readybuild aims to simplify the process and remove the hassles from the re-bar usage in construction. This is a service which aspires to replace a substandard existing practice, marred with multiple problems, with a superior and new-age technological solution. However, establishing a new service entails the responsibility of guiding the customers through the entire process. To attain this, each of the Readybuild centres have an after-sales team, which along with the production team; take the customers and their site team through every step of the process in complete detail. the Readybuild team takes the onus of seeing the job end-to-end, right from the bar-bending schedule to providing identification tags for each shape, and guiding the site team on the delivered stacks.

Tiscon Readybuild has already been successfully adopted by countless customers in transmission and distribution, MRTS, windmills, housing and commercial segments. Other segments in construction are also warming up to the cut and bend solutions offered by Readybuild.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.