Twiga is one of the leading manufacturers of fibreglass wool insulation in India with a 30-year track record of supplying domestic and export customers with world-class products for thermal and acoustic insulation. The hallmark of Twiga products are its superior fire properties and its extremely cost-effective nature.

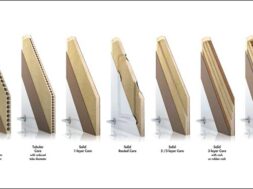

Suitable application areasBuilding envelope: Energy-efficient roof, wall and facade. Twiga Insul helps to comply with ECBC recommended U-value or R-value for 12-or 24-hour buildings. Products like faced and un-faced fibreglass wool insulation boards are suitable for underdeck, cavity wall, wall lining and facade assembly.

HVAC: Twiga Insul is recommended for duct wrap and pipe insulation for central air-conditioning systems. Aluminium or special polypropylene faced flexible blankets are used as duct thermal along with compatible sealing system. Twiga also provide flexible insulated or un-insulated ducts and prefabricated non-metallic duct boards against conventional metal ducting plus insulation. AHU room, mechanical room and duct acoustic lining can have Twiga Insul fibreglass wool acoustic boards with laminations like tissue or woven glass textile.

Drywall partition: Low density resilient fibreglass wool helps achieve high acoustic isolation in dry wall partition without increasing the load in the assembly. Different acoustic tests as per international standards established the compatibility of Twiga Insul with drywall system/products of various manufacturers.

Pre-engineered factory buildings and light gauge/pre fabricated structures (e.g low cost housing): Tough and flexible insulation blankets of customised lengths with special facing and tabs are applicable for metal building roof and wall insulation. The product is easy to handle and install, and meets best thermal, acoustic and fire-safety features.Other segments include cold storage, bus body, metro rail cars, long distance rail coaches and many other processes/niche segments.

All of its products are made of high-quality inorganic and non-combustible fibreglass insulation in various forms and shapes, optionally laminated with imported facings. Being a technical licensee of Saint Gobain-Isover, Twiga has adopted the world-class TEL technology in manufacturing. In this process, the complete raw material is converted to 100 per cent pure fibre and free from slag, metal-shots or any un-fibreised elements. This ensures better quality and long performing life of the product and its associated system.

Its products’ general features include high thermal resistance, high acoustic absorption, fire safety, hydrophobic nature, chemical stability, shot free and resiliency. Basic material hasfire safe features like non combustibility, non toxicity, limited or zero spread of flames (Class ‘O’/Class 1). It is pure and does not settle down. It complies to general standards of IS: 8183, IS:3346, IS:3144 and IS:9842.

Twiga Insul has been awarded various approvals from Navy, FM Global, EIL, and government authorities like CPWD, NTPC, MES etc. It is also included in green product directory of IGBC and TERI-GRIHA/SVAGRIHA. It is one of the preferred insulation materials for sustainable construction and being supplied either directly or through distribution network in various prestigious projects in India. Twiga Insul is also now present in South-East Asian countries like Sri Lanka, Hong Kong, Singapore and Vietnam along with other Asian and African countries.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.