Build smart infrastructures with Outinord

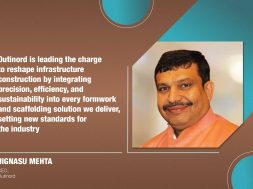

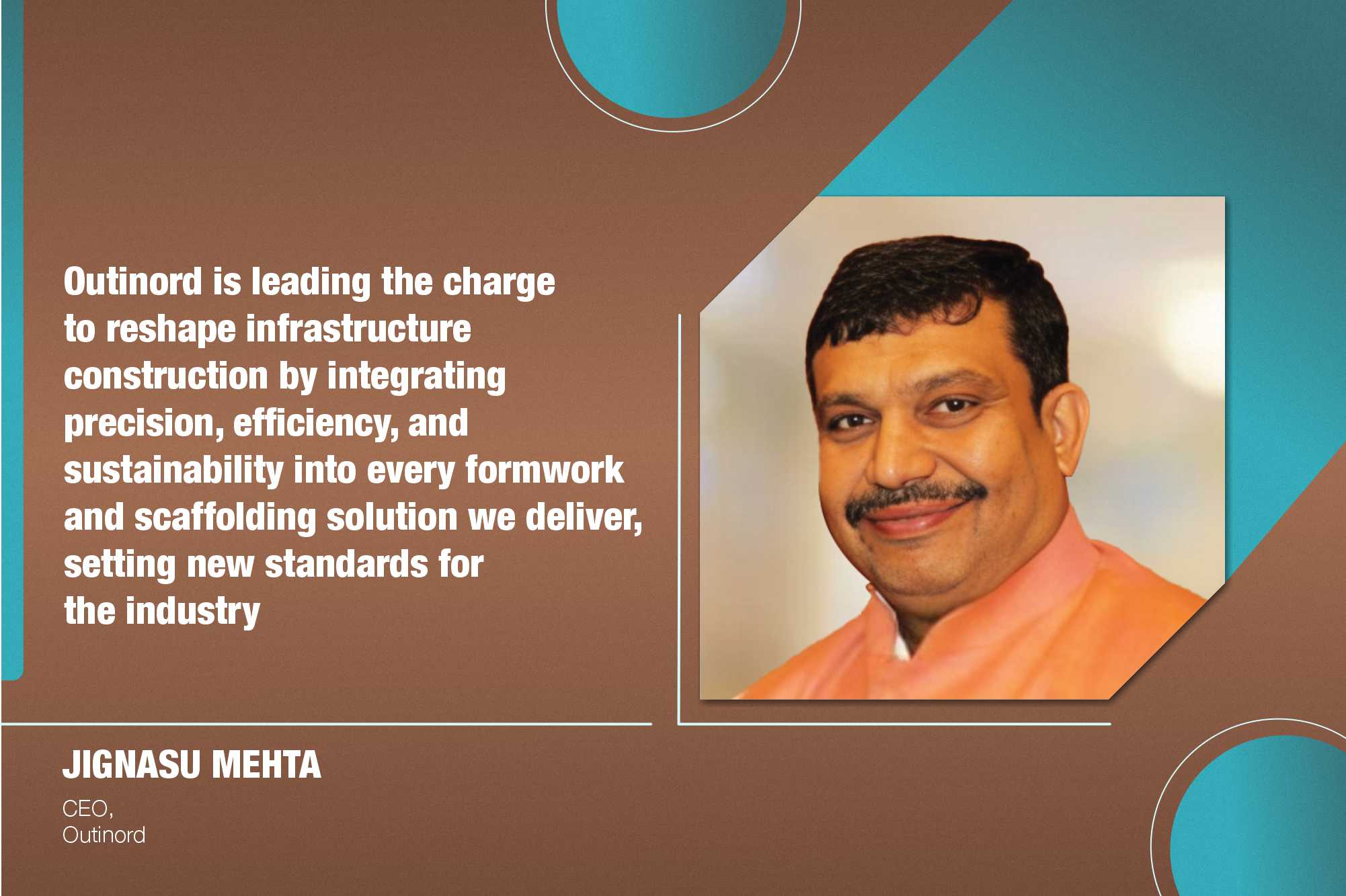

“Outinord is leading the charge to reshape infrastructure construction by integrating precision, efficiency, and sustainability into every formwork and scaffolding solution we deliver, setting new standards for the industry.” Jignasu Mehta CEO, Outinord.

This discussion explores the latest trends, successful case studies, and the unique advantages that Outinord’s solutions bring to large-scale infrastructure projects and how they pave the way for the future of construction.

What emerging trends in formwork and scaffolding do you see influencing the infrastructure sector in the near future?

The infrastructure sector is rapidly advancing in formwork and scaffolding technologies. Modular and prefabricated systems are gaining popularity for their speed, safety improvements, and cost reductions. These innovations promote standardisation and reusability across projects. Sustainability drives further innovation with eco-friendly materials and designs that minimise waste and energy consumption. Lightweight, high-strength materials enhance portability and structural integrity. Safety remains a top priority, leading to advanced fall protection systems and real-time structural monitoring. Automated climbing formwork systems are increasingly used, reducing risks associated with manual labour at heights. These trends significantly enhance productivity, safety, and sustainability in infrastructure projects.

Can you share some case studies in which Outinord’s formwork and scaffolding systems have been pivotal in completing infrastructure projects successfully?

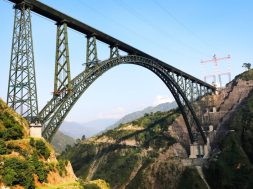

Outinord has demonstrated its capabilities through several notable projects in India. For instance, they supplied Wagad Infra Projects with piers measuring up to 6 meters in height and 1.75 meters by 1.75 meters in size for the NH 68 Highway project. They also provided a precast mould for the pier cap, enabling Wagad Infra to complete the pier and pier cap casting in a single day. This approach significantly reduced project duration while enhancing quality and efficiency. By leveraging Outinord’s advanced formwork technology, Wagad Infra achieved superior quality, accelerated project completion, and substantially lowered labour costs. We supplied a modular system to our esteemed client, N G Project, for constructing box culverts of various sizes for a highway project. They later reused the system with minor modifications for the SVUP and LVUP projects, avoiding the need for different formwork solutions. These projects exemplify Outinord’s ability to deliver exceptional building solutions that are cost-effective, timely, and uphold rigorous safety and durability standards.

How adaptable are your formwork and scaffolding systems to various infrastructure projects?

Outinord’s versatile formwork systems are ideal for infrastructure projects, including bridges, high-rise buildings, and industrial facilities. Their modular design allows quick assembly and disassembly, reducing on-site time and labour costs. Tailored solutions are available for complex geometries and are compatible with concrete, steel, and prefabricated elements. Integrated safety features meet international standards. Our systems handle different heights, loads, and concrete pressures, making them suitable for renovations and new constructions. Innovative column forms allow rapid construction of square or rectangular columns, with up to eight columns completed daily by a six-person team. Adjustable pier caps and tie-rod-free pier formwork enhance efficiency, using a single mould for multiple sizes.

What unique advantages do Outinord’s formwork systems bring to large-scale infrastructure projects compared to traditional methods?

Outinord Formwork systems revolutionise large-scale infrastructure projects with key advantages over traditional methods. They ensure superior precision and uniformity in concrete shapes and finishes, minimising rework and enhancing quality. The modular design allows quick assembly, disassembly, and reuse, significantly accelerating construction timelines and reducing labour and equipment costs. Safety features like guardrails and stable platforms prioritise worker well-being by reducing on-site accidents. Our adaptable systems accommodate complex geometries and varying heights, enabling innovative designs that traditional methods may struggle with. This flexibility fosters creativity in infrastructure projects. Promoting sustainability, our formwork systems minimise material waste, aligning with modern construction practices. Through ongoing innovation, Outinord remains at the forefront of efficient and adaptable infrastructure solutions.

For more details , Visit : https://outinord.net/

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.