HCC completes first tunnel for Kishanganga project

HCC builds India’s first tunnel using Tunnel Boring Machine in Himalayan terrain

Engineering major HCC has completed the construction of first 14.75-km tunnel in the Himalayan terrain that will carry water from Kishanganga dam for a 330-MW hydroelectric project being developed on it.

The hydel project is located on River Kishanganga, a tributary of river Jhelum, in Bandipore district of Jammu & Kashmir. HCC and the UK-based Halcrow Group are jointly executing the project worth ` 2,726.49 crores for the National Hydroelectric Power Corporation Ltd. (NHPC). The project involves transfer of water of Kishanganga River in Gurez valley to Bonar nallah near Bandipore in Kashmir valley.

“HCC has made history by successfully completing the first tunnel constructed using Tunnel Boring Machine (TBM) in Himalayan Terrain for its Kishanganga Hydroelectric Power Project in Jammu and Kashmir,” a release issued by the company said.

Kishanganga Hydroelectric Power project is being constructed by HCC on EPC basis. The project has a 23.65-km long Head Race Tunnel to carry the water from dam to the powerhouse. The tunnel is constructed using two methodologies – 14.75 km tunnel is constructed by TBM and the remaining 8.9 km tunnel is constructed by conventional drill and blast method. This is one of the Longest HRT in India with maximum overburden (height of mountain above tunnel) of 1,470 metres.

Speaking on the occasion, A.I. Benny, Project Manager HCC said, “Using tunnel boring machine in young Himalayan Mountains poses various geological and technical challenges. We are indeed proud of having a capable team that took up this challenge and with meticulous planning and precise execution overcome all hurdles to complete the tunnel well ahead of time.”

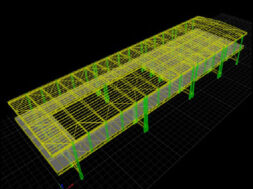

A state-of-the-art Double Shield TBM was ordered from SELI of Italy for this specialised job. The 225 metres long TBM with a cutter head of 6.18 metres was transported to the project location via Mumbai in 160 container shipment. Transporting the machine to project location in Jammu & Kashmir was a major logistical challenge which was completed in three months. The TBM commenced its first drive on April 20, 2011 and completed the tunnel with average monthly progress of around 500 metres. In November 2012, HCC made a national record of highest monthly tunnelling progress of 816 metres at Kishanganga project. n

Project’s Major components:

• Dam – 37 metres high Concrete Face Rock fill Dam (CFRD) • Diversion Tunnel – 9.5 metres diameter, 560 metres long diversion tunnel• Head Race Tunnel – 23.65 kms long Head Race Tunnel to carry the water from dam to the powerhouse – one of the longest HRTs in India with overburden (height of mountain above tunnel) of 1,470 metres.• Construction of HRT is carried out using two methodologies. The 8.9 kma tunnel of 6 metres diameter from the dam side is constructed using the conventional Drill and Blast Method while the balance 14.75 kms with a finished diameter of 5.2 metres from the powerhouse side is constructed using TBM• Tail Race Tunnel- Tail Race system discharges water back into the stream after power generation and comprises of 862 metres long and 5 metres diameter D-shaped tunnel and a 44 metres long open channel.• Surge Shaft – It is a part of the water conductor system to power house located at the end of the HRT which acts as a balancer to absorb the effect of water hammer when the water in motion is forced to stop. The Surge Shaft at Kishanganga is a vertical shaft of 18.75 metres diameters and 100.7 metres deep.• Pressure Shaft – One steel lined pressure shaft 4 metres diameter trifurcating at the bottom into three penstocks 2.1 metres diameter each to create pressure in turbines for power generation. • Power House – The underground power station consisting of two parallel caverns, one for the three generating units and the other for tra–nsformer• Switchyard – A surface switchyard

32

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.