Afcons plays key role in widening NH1-A to 4 lanes; creates record for fastest completion of hill-road project

Gone are the days when you would have to drive through the rolling terrains of Jammu to reach Udhampur after a two-and-a-half hour drive. The four lane of the section between Jammu bypass and Udhampur has reduced the travelling time to just 45 minutes. Afcons, working on the corridor, has completed the project in a record time. In the National Highway Authority of India’s (NHAI) history, this is the fastest hill-road project by an infrastructure firm in India.

Complimenting Afcons’ efficiency in the project, RP Singh, Project Director, NHAI, said, “The scheduled period to complete the project was 36 months. We were anticipating slight delay due to topography and other problems. Fortunately, we have got a very good contractor [Afcons] and a good concessionaire [Shapoorji Pallonji]. This will be the fastest project in the hill area of the country where we are able to complete the project well ahead of schedule. In that way, it’s a landmark project.”

The needExpansion and development of efficient road network is one of the pre-requisites for a country’s economic progress. Roads are a preferred mode of transport in India and statistics suggest that highways carry 60 per cent of freight and 80 percent of passenger traffic. The traffic on national highways is estimated to grow by 8-10 per cent per annum in the coming years. For several decades, NH1-A has served as the vital link between the nation’s frontiers and its coasts. This road enables the mobilisation of soldiers and weaponry to forward positions during conflicts. Its renovation and re-alignment is part of the Phase-II National Highways Development Programme (NHDP), entrusted to the NHAI by the Government of India.

The beginningInterestingly, the project started in 2011 with just 35 per cent of land available. The 65-km stretch had to be closely monitored and over 8,000 workers were deployed to finish the job before time. To ensure the project didn’t get delayed, it was divided into two sections: Jammu and Udhampur. Separate crack teams were created under Arun Kumar Mishra, who led the Jammu section, and Ananta Kumar, who headed Udhampur. Special incentives were given to workers for completing certain jobs on time. Together, the teams worked round the clock to pull off a national record.

Project importanceThe NH1-A has an economic, cultural and strategic importance. Every year, it carries thousands of devotees and tourists to the shrines of Amarnath and Vaishno Devi, as well as to Srinagar and Leh. The military movement is also high due to Jammu and Udhampur being the army’s nodal points.

“This route is very important due to the movement of the armed forces to the national border. The valley is cut off during winters, so the movement of daily commodities through this corridor is of significant importance,” Singh said.

“At present, around 15,000 vehicles ply daily on this route. Out of that 3,000 vehicles are of the defence alone. There’s to-and-fro military movement throughout the year,” he added.

Any road-development activity on this corridor demands a smooth traffic diversion plan. Afcons made sure the existing traffic was not disturbed at any stage of the project. “Afcons has managed the traffic beautifully. During the entire duration of the contract, there was no disturbance to the traffic. We were able to make available, at least, two lanes for vehicles during construction work,” he said.

Difficult terrainThe existing road is strewn with blind curves making driving extremely dangerous. Any minor to fatal accident, at present, stalls traffic for hours. The new alignment has less curves and wider bends that allow an average speed limit of 60 kph (earlier the average speed was 25-30 kph). Passenger safety is taken care of at all points and a smoother navigation significantly cuts down chances of accidents.

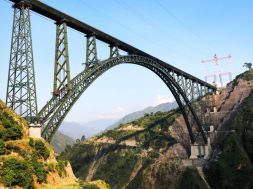

The existing highway is along a hilly terrain, winding through wildlife areas. Also, blasting is not allowed during construction in Jammu and Kashmir. Excavation had to be done by rock breakers, and environmental safety norms were strictly followed. The construction of innumerable bridges, viaducts and underpasses posed a major challenge to meet the deadline for the project.

“Though we call it a road project it’s actually a project of structures. Rarely, we see a highway with 76 bridges/viaducts and underpasses, 223 culverts, 10 km of retaining wall, 27 km of breast wall, four twin-tube tunnels etc. It is not a conventional road project,” said Ananta Kumar.

Sharing his thoughts, K. Subrahmanian, VC and MD, Afcons, said, “The project demonstrated the very theme of operational excellence that AFCONS has developed as a key differentiator vis-a-vis its competitors. While many road projects in the country have been delayed, this project comes as a whiff of fresh air and as a new business model not only for Afcons, but also for the nation as a whole. I believe that such an achievement will motivate others to emulate.”

Shapoorji Pallonji, the concessionaire for the project, has shown tremendous support for Afcons. Col Sanjiv Puri, who was team leader for SP JUHI, explained how flexibility and resource mobilisation became a recipe for success. “The logistics of this project has been managed very well. Every facet of road-building has been dealt with in the project. So this gives us the confidence and an edge over our competitors. We can perceive much better and execute much better,” he said.

Better road connectivity will boost the economy of Jammu and Kashmir and bring the people of the valley closer to mainland. Afcons takes pride in bridging the gap and fostering a socio-economic boom in the northernmost state of India.

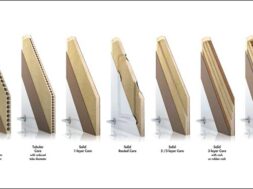

Value engineeringTender proposal of cast in-situ box girder bridges with various spans has been re-engineered to evolve bridges with standard 20-m spans with precast I girders. This has reduced the time of construction and reduced manpower requirement

Gabion walls were constructed where the retaining wall is designed up to 6 metres in height. Whenever retaining wall heights were more than 14 metres, combination of RE wall and retaining wall was adopted. Tender proposal of slab culvert was converted to box culvert.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.