“Supreme has completed this project in 28 months which was 2 months before contractual completion date,” says Mahesh Shejwal, Head – Infrastructure, West Zone, Supreme Infrastructure India

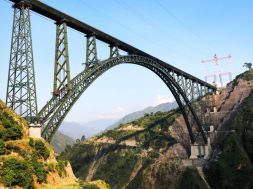

Kasheli Bridge project was awarded to Supreme in 2009 by Sangam Group. The project has received an industry honour for its outstanding contribution in specialised construction as well as involved complex engineering skills to cast pilling with depths ranging from 15-25 metres. Mahesh Shejwal shares how this project has become an engineering marvel and a reflection of Supreme’s in-house capabilities.

Location The site was located near Thane and 15 km away from Mumbai. The project has its connectivity between Bhiwandi and Thane on old Mumbai-Agra Road (NH 3). It is an important road connecting Thane and Bhiwandi Municipal Corporation limits. Bhiwnadi, the warehouse hub for products like electronic goods, furniture and vehicles, supplies products to Mumbai and other suburban parts of Mumbai.

The objective of this project was to minimise traffic between Mumbai and Bhiwandi.

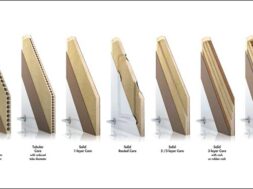

Project in parts• South Kasheli is consisted of construction of two bridges (552 RMT each) of three lanes on either side of existing bridge over Kasheli creek. It involved 28 foundations with 204 No 1,500 mm diameter cast in situ driven piles of average depth of 30 metres in 22-25 metres standing water, superstructure with 26 numbers pre-stressed concrete box girders of length 42.5 metres each.

• North Kasheli is consisted of construction of two bridges (135 RMT each) over Kasheli creek. The work involved four foundations with 48 No 1,500 mm diameter cast in situ driven piles of average depth of 20 metres, superstructure consisted four spans of 33.75 metres with mild steel trusses and two central spans of 67.5 metre mild steel through truss.

• Road Work is consisted of design and construction of 8-km flexible, rigid pavements with all cross drainage works and construction of toll plaza.

Technical difficulties/problems and solutionsInitially, the bridge foundation was designed for well-type foundation, but it was very difficult to complete all the 36 foundations in 12 months due to 22-metre standing water depth, high water current and tidal variation of 4 metre. With the help of designer, the well foundation was replaced with pile foundation. Cast-in-situ piles with the help of hydraulic rotary rig (IMT-AF220) were mounted on mechanical spud barge of 1,200-tonne capacity. While doing the pile cap, Supreme has faced a lot of problems to adopt adequate supporting system, and it spent 32 days to cast first pile cap. Then with the help of marine expert and designer, Supreme adapted suspended support system for pile cap, and it has reduced time by 15 days per pile cap.

Due to local resistance from fishermen to work in navigational span and construction difficulties, Supreme has replaced pre-stressed box girder with mild steel through truss of central span (67.5 metres) of north Kasheli Bridge.

Meeting goals and requirementsWith strong vision, will of management and support from office, Supreme has completed this project in 28 months which was 2 months before contractual completion date. Supreme has followed all standard procedures and specifications as per client.

Dream projectKasheli Bridge, Thane• Client: PWD (Special Projects), Thane• EPC Contractor: Supreme Infrastructure India Ltd.• Project cost: ` 227 crore (Bridge – ` 139 crore; Road – ` 88 crore)• Status: completed in 28 months

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.