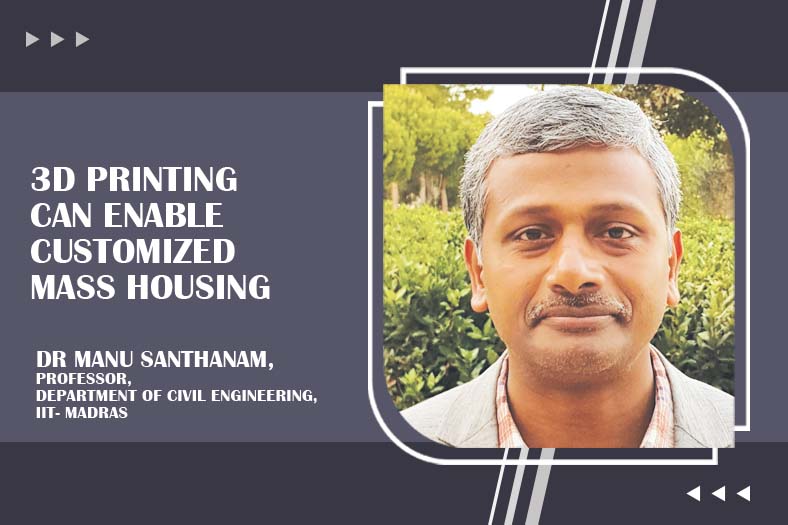

3D printing can enable customized mass housing

At present, however, it is important to spend more time on research and demonstration projects, and also to achieve the necessary certifications. The technology would be ready for deployment possible in another two years says Dr Manu Santhanam, HOD, Department of Civil Engineering, IIT- Madras

What are some of the new-age technologies that allow contemporary construction processes to be innovative yet sustainable?

Innovation in construction projects can be brought about in terms of the materials used and the process itself. There have been significant advances in cement based materials in the last decade that can enhance the quality and speed of construction (covered in detail in the next point). Further, the construction process itself can be optimized in several ways in order to minimize waste in resources and time. Technologies such as Precast volumetric construction / Aluminium Formwork construction / 3D printing can speed up the delivery of construction projects. Additionally, 3D printing also helps in optimizing the amount of material that needs to be used. The adoption of lean construction approaches can further help accelerate the progress of construction projects, by providing the tools for visualization of the project as it progresses.

What are some of the time-tested as also emerging construction materials that offer flexibility in terms of design whilst ensuring the end product is aesthetically pleasing and robust?

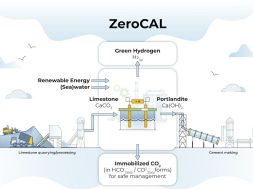

While concrete is still the primary building material, current efforts are towards reducing the extent of cement usage in concrete, in order to lower the net CO2 impact of concrete. The increased level of understanding of supplementary cementing materials such as fly ash, slag, calcined clay has paved the way for more innovative cementitious binder systems that can impart high durability to the concrete. Advances in nano materials have also contributed to producing niche concretes such as self-cleaning concrete (which is made possible by TiO2), and conductive concrete (which has carbon nano fibres / carbon nano tubes to provide conductance, and also improve the resistance to microcracking). Also, the use of fibres (mainly steel, but sometimes also glass and polypropylene) intermixed into the concrete has made it possible to produce thin and slender concrete sections.

How is 3D printing fast emerging as a viable alternative in construction? What are the limitations which need to be overcome?

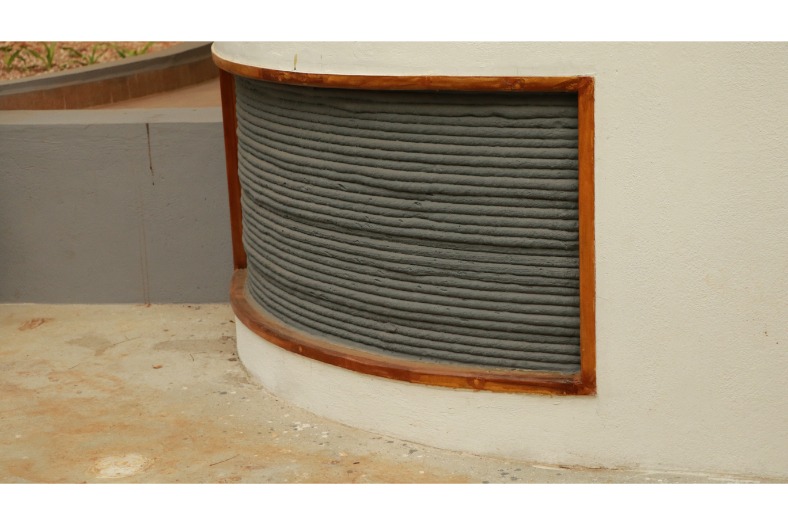

3D printing employs the understanding of manufacturing processes in order to improve the productivity of construction. The combination of materials used in 3D printing is based on a scientific process of mixture design which leads to the unique characteristics required from such a concrete. With 3D printing, it is possible to construct concrete structures with sufficient geometrical flexibility. Also, there is no need for formwork, implying a significant saving of costs and time. There are of course significant challenges with 3D printing – ensuring a robust design of the concrete to achieve printability is one issue, added to producing affordable printable concrete mixes that use less cement. The principal challenge is in introducing reinforcement in the 3D printed structures, and scaling up the process.

In a country like India where affordable homes are key to ensure ‘Housing for All’ what role can 3D -printing play? How soon before we see large-scale adoption of this technology in Indian construction?

3D printing can enable customized mass housing – i.e. even in cluster houses, it is still possible to achieve economy when the individual home owners desire different features and shapes in construction. This is not possible with other mass housing technologies such as precast. With appropriate research and development, affordable solutions to the materials used in 3D printing can be suggested, which will cut down the overall cost of such construction. Moreover, the saving of time and labour for construction would also bring it into the affordable range, as long as sufficient scale of work can be done. At present, however, it is important to spend more time on research and demonstration projects, and also to achieve the necessary certifications. The technology would be ready for deployment possible in another 2 years.

33

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.