Dextra concrete reinforcement and GFRP products are suitable for precast construction

Satish Priyadarshan V, Product Line Manager of Dextra Group, talks about the demand for precast structures in a new market.

Can you discuss the latest demand trends for precast concrete across construction and infrastructure projects?

Demand for precast structures has been consistently increasing. The good part about this development is its overall development. All the sectors are exploring the option to use precast technology in their respective projects, and the number of traditional precast users in residential and office space is consistently increasing.

How do you see the demand for precast materials in the market?

Over the years, there have been many new entrants in the precast market, and this success in a new market has a ripple effect. For example, precast boundary walls and drains are part of one such success story where the industry is moving towards mass production, and the products are getting standardised.

How does your range of products and solutions complement sustainable construction?

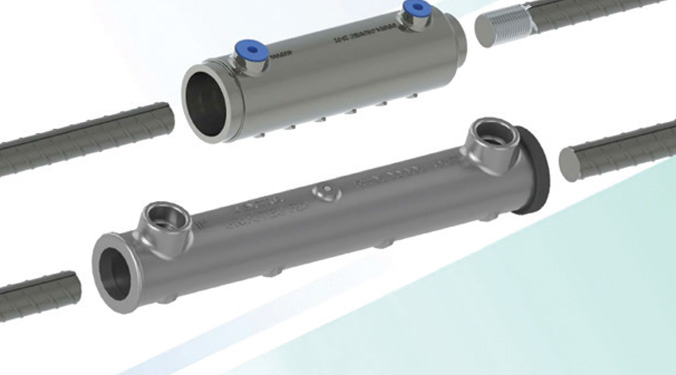

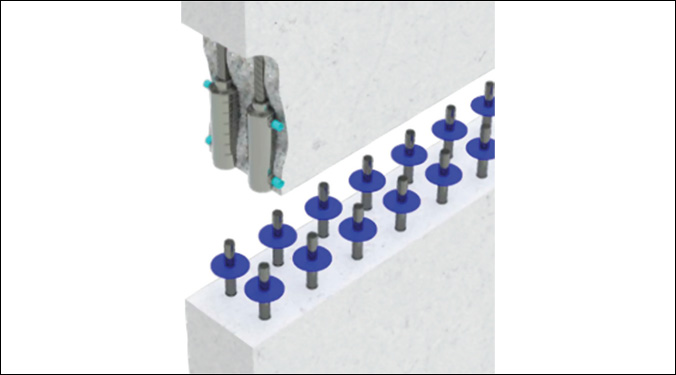

Dextra has various solutions complementing the precast industry. We have a dedicated, tested, and proven coupler connection that offers bar-to-bar connectivity, vital for precast construction emulating cast-in-situ construction. Precast construction is about concrete members manufactured in factories. At the same time, Dextra concrete reinforcement products and GFRP products are suitable for precast construction. Dextra threading machines adapt better to factory environments and are designed to meet higher load capacities.

How do you ensure reliability and stability for the solutions?

Our concrete reinforcement products follow a global design and are tested for various standards. This universal approach makes all our products reliable and sustainable.

How do you look at the need to recycle and reuse the waste generated from a project?

The best way to save the environment is to avoid waste. Our flagship product answers this magnificently by reducing rebar waste effectively. Reduced waste is a step toward environmental sustainability.

What are the innovations we can expect from you this year?

We have been working on the thermal conductivity of precast sandwich panels and have also come up with an innovative solution called Precast Tie.

for more info visit : https://www.dextragroup.com/

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.