Creating Tomorrow’s Buildings with 3D Printing

The breakthrough technology that made a significant impact on the construction industry in 2016 is 3D Printing.

Technology can do wonders

Technology could do wonders in terms of speed if selected appropriately and save a lot of time in the construction phase – which invariably lands up being a saving for the project in the big picture as your delivery is expedited. “Initially, any technology would cost higher than the conventional method, however, post factoring the time value of money and taking into account the faster delivery it facilitates it’s a sure shot winner in the whole project cycle,” says Raman Sapru, President, EPC, Omkar Realtors & Developers Pvt Ltd.

Today we cannot think of any high rise building without technology. Also, we are surrounded by technology 24/7 that it is a must in the future apartment one would want to stay. Today newer developments especially the luxurious facilities like the company’s Omkar 1973 Worli and Alta Monte, Malad are equipped with well-integrated systems of data/telecom/security and CCTV surveillance and the elevator management system in place for the comfort of the residents.

As per Sapru some of the latest technologies that are responsible for the transformation of the construction industry are 3D BIM that helps the workers to imagine and deliver the same way they thought of 4D and 5D are responsible for better cost-effective model designing with comparative lesser time than the usual model would take. 3D laser scanning is one that helps in understanding the exact dimensions of a project using this form of construction technology means there is no reliance on human measurements, and so reducing human error.

Building with 3D Printing

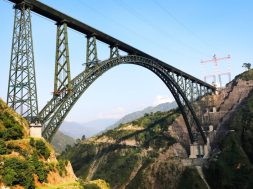

Stating upon the 2016 breakthrough technology Sapru said, “The breakthrough technology that made a significant impact on the construction industry in 2016 is 3D Printing. This technology allowed the parts of the building structure or the entire structure to be manufactured using concrete printing technologies.” In addition innovation in powered robotic exoskeletons that can be fitted to the arms of the workers to boost up the strength and accuracy in construction.

On the other hand advancement in Drone technology has helped the construction industry to minimise the time and costs in expensive surveying using expensive surveying tools and heavy equipment. These flying gadgets installed with high-resolution cameras are already forming an integral part of business operations of some innovative construction firms. “With the advancement in 3D modelling technology and extreme resolution cameras, 3D models of construction sites can be designed in no time. Drones can also be used to keep a schedule on track and reduce downtime, ensuring efficiency of workers onsite. Detailed shots taken from a drone can keep the project manager and promoters constantly up to the date on the progress of a project, especially in large construction sites like townships, highways, and airports,” adds Sapru.

Smart wearable sensors that are being used to track workers have also made the positive impact, especially in terms of workplace safety. Smart sensors embedded in the boots, helmets and wristwatches helping the construction industry to get the real time data on the employee’s health and safety and surroundings. For instance, sensors fitted in helmets can alert managers in the event of an incident occurring. “In the future, we can expect these helmets to be smart and include augmented reality where workers can safely map their environment and monitor metrics,” says Sapru.

Similarly, advancements in telecommunication and information technology helping the construction industry to track and monitor their equipment in real time. The Telematics technology achieved two major benefits to the industry like streamlining the resource allocation for optimum usage; and reduction in theft.

Technology adds value

Briefing on how this technology added value to your business Sapru said, “There is no single solution to a project. Depending on the context we decide equipment and technology. Today’s project, have fast track deliverables promises to match with customer requirement and competitive market demand, to foster this, technologies amalgamating operations are to be used. Mini plaster machines, wall chasers, proper sequencing, ready-made doors, drywalls mechanism, aluminium section lintels, weldmesh and many more.”

Following are the factors that has added value to the profession are:

• Robust technologies in glazing façade, high-speed elevators, smoke detectors, ducting, and chillers are also a part of today’s fast track high rise projects.

• The technological capability exists for vast improvement in our methods, and it will be our effectiveness that determines our success in the long run.

• Technology has helped speed up a variety of our processes, like time tracking and resource management.

• Productivity in construction receives a substantial boost from standardisation, modularisation, and prefabrication.

• Basic intent of technology in today’s fast track high-rise structure is to minimise timelines with the best quality guarantee, technological development in formwork, high grade concretes, plasticisers, design intents all add to a benefited high-rise project.

• There must be equilibrium balance upon products, design intent, and technology development.

• High-speed elevators with machine room and mini machine room – faster lifts mean safe journeys for passengers and, as a result, better customer satisfaction, auto-climbing formwork system – it features great adaptability to complex geometries and exposed concrete finishes, but above all it is a system that is remarkable for achieving optimised working times and rhythms during the climbing, concrete pouring and stripping processes, with total safety.

• Drywall construction became prevalent as a speedier alternative to traditional plaster. Mast climbers provide fast, efficient and affordable temporary access to a wide range of construction and maintenance work, GPS can be used for many tasks in construction surveying such as measuring the grading, elevation, staking, mapping and site exploration

Embracing new technology on need-based

The company is using a host of technologies for faster construction ranging from aluminium shuttering, self climbing form work, quick deck system for slabs, to name a few. The tunnel form and jump form systems have helped us to reduce the turnaround time considerably.

“Recently we also employed drones to capture imagery and videography of Omkar 1973 Project to aid our marketing campaign. We at Omkar are always open to embrace any new technology on need-based,” adds Sapru.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.