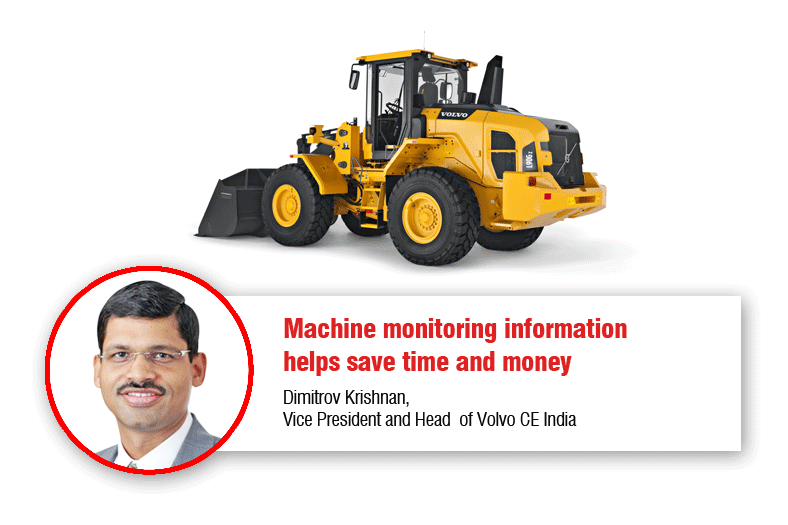

Machine monitoring information helps save time and money

Thanks to the current infrastructure push to build smarter cities on the back of government’s increasing focus and spending on the same, Volvo Construction Equipment (CE) is witnessing rise in demand for its equipment. The company aims to continue providing fuel-efficient products that aid productivity, according to Dimitrov Krishnan, Vice President and Head of Volvo CE India.

How do you see the demand for your products?

Volvo EC200D, which was designed specifically for general construction work, is attracting strong interest. The excavator features fuel efficiency, a bucket breakout force of 123 kN and an arm tearout force of 96 kN, which helps it deliver high job site productivity and fast cycle times.

Volvo’s equipment, irrespective of the demands of infrastructure or construction job, offer the company’s hallmark qualities: industry-leading fuel efficiency and productivity levels that customers love world over—particularly in India. Volvo machines deliver the fuel savings they want, albeit without the need to take on newer hybrid systems, utilising proven designs instead.

How are your products adding more value to construction?

Increasingly, customers need to do more with less. That’s why most of them have opted to monitor their fleet with our telematics system. CareTrack is a telematics system that gives equipment owners access to a wide range of machine monitoring information that can help save time and money. The system generates a wide range of reports with data on aspects such as fuel consumption, operational hours, geographical location and more. It can also be used to manage machine servicing and wear parts. This allows fleet managers to reduce fuel costs, optimise machine and operator performance, as well as proactively manage service and maintenance to maximise uptime.

The insight provided supports customers with maintenance, invoicing, fleet management and operator training. Customers can monitor load efficiency, number of cycles, overload percentages and identify operator training needs. Owners can tap into a wealth of actionable data including fuel consumption, idle time, machine location, fluid levels and service alerts. With time and labour savings, customers say they view it as an investment rather than extra costs. It is a great way to proactively manage machines and increase uptime by planning service and maintenance requirement, in advance.

Discuss about your latest product or innovation?

Volvo CE introduced the G-Series L90Gz wheel loader and the DD100B double drum asphalt compactor during bauma CONEXPO India 2018. We presented the L90Gz and the DD100B. The Volvo G-Series L90Gz loader with Z-bar linkage is now available in India with a BS-III certified engine, offering high torque at low rpm to ensure low fuel consumption. The wheel loaders feature maximum power of 175hp at 1700 rpm, maximum breakout force of 168.7 kN, max. static tipping load of 10,380 kg at full turn, and is available with buckets ranging from 2.4 m3 to 4.5 m3. Volvo CE’s double drum compactors feature independent dual-frequency and multi-amplitude functionality which makes them more versatile.

Volvo machines deliver the fuel savings they want, albeit without the need to take on newer hybrid systems, utilising proven designs instead.

Dimitrov Krishnan, Vice President and Head of Volvo CE India

23

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.