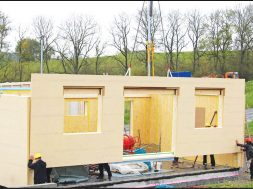

Towards ecological, rapid construction

Adequate use of innovative techniques, materials are imperative for building roads and bridges faster and better.

The road sector produces the highest level of greenhouse gas, directly, through fossil energy used in mining, transportation, paving works and indirectly through the emissions coming from vehicles. Environmental laws are getting stricter in order to reduce the air pollution and noise disturbances so it has become extremely important to construct sustainable eco-friendly road.

Expediting construction process

A rigorous R&D process and optimal utilisation of the available resources helps in speeding the construction process. With lot of mechanisation, and drastic change in construction methodology construction process will be expedited. Reduction in construction cycle time by adopting techniques and methodologies which are in sync to the construction process hereby reducing the cycle time of a particular activity.

“Use of precast technologies in precast bridges culverts drain has helped industry to meet high volume requirements and to stick to project milestones,” says Ratan Lal Kashyap, Sr. Vice President – Procurement, G R Infraprojects Ltd.

Eco-friendlier road construction

G R Infraprojects uses road milling technology; milling machine has helped use of reclaimed asphalt pavement (RAP) which was a waste and damage to environment when dumped on road side. Reuse of RAP has helped save mining of aggregates and sand which is damaging the environment in the long run. The optimal use of bitumen in RAP also reduces the additional bitumen percentage in asphalt mix, says Kashyap. Foam bitumen technology involves bituminous paving mix recipe by injection of bitumen in the form of foam into the aggregates predominantly constituting the scrapped or milled aggregates from the existing road. This helps in reducing the carbon footprint by using cold mix and lesser emission of fumes or greenhouse gases – GHG (CO2, SO2, NOx and more).

Role of geosynthetics

The flexible pavement is a structural entity comprising of components of granular material of different gradations (base course and subbase course), placed on the dressed original soil. According to Shahrokh Bagli, Chief Technology Officer, Strata Geosystems (India) Pvt Ltd, if the soil is weak, the pavement components need to be stronger to carry the wheel loads several million times over. One way of achieving this if the subgrade soil is weak is to judiciously increase the thickness of the components. This is an expensive proposition and in present times, not conducive to the environment, particularly with restrictions on quarrying of natural materials. An eco-friendly way is to reinforce the pavement components with polymeric geosynthetic reinforcement.

There are two types of reinforcements for the flexible pavement; geocells and biaxial geogrids. Each has its own functional philosophy. Geocells confine the material within which the reinforcement is laid. Owing to such confinement, it improves the performance of the road by enhancing the resilient modulus of the component within which the geocell layer is placed by 2.5 times, at times even 3 times over. Biaxial geogrids are those with equally high strength in both machine direction and the cross-machine direction. The performance of biaxial geogrids is different. It holds the material together either by friction (flexible geogrids) or interlocking (rigid geogrids).

There are two types of geosynthetics used for the protection of roads and pavements; geogrid and non-woven geotextile. Geogrids are geosynthetics which transfer load of vehicles to a larger area of soil thus, is most effective for reinforcement. It greatly increases the stress bearing capacity of the soil and also reduces aggregate layer thickness by up to 50 per cent. Non-woven geotextile is a permeable fabric which when used in association with the soil has the ability to filter, reinforce, drain and separate. It also acts as a filter media hence prevents potholes and greatly increases the life of the road, according to Kartik Kanodia, Director, Manas Geo Tech India Pvt Ltd.

Normally, a flexible road pavement suffers from two types of failures – rutting and fatigue cracking. These occur owing to strains exceeding limits at two points in a pavement. The introduction of geocells and geogrids improve these moduli in the respective layer that these are placed to provide more economic (thinner) pavement components. This in effect makes design economical, saves cost and construction time. With the need for less quantity of natural material, use of geosynthetics in flexible pavement sections offer an eco-friendly solution, he adds.

Following are the key functions of geogrid and non-woven geotextile by Kanodia to improve the quality of roads:

• Re-enforcement: Use of non-woven geotextile and geogrid help to increase the overall strength of the roads. They prevent lateral spreading of the base, increase the confinement and also improve the vertical stress distribution of the sub-grade. Use of non-woven geotextile and geogrid improves the stress bearing capacity of the road by more than 50 per cent.

• Separation: Non-woven geo-textile prevents mixing of different layers of soil namely subgrade and aggregate. This separation prevents contamination and helps each layer distinctly perform its functions.

• Drainage: Due to high permeability, non-woven geo-textile allows water to flow freely along its plane. Thus, there is adequate liquid flow which in turn prevents soil loss.

• Filtration: Non-woven geotextile allows liquid flow through its plane and prevents soil to pass through its surface hence, acts like a perfect filter media. Manas Geo Tech skillfully manufactures non-woven geotextile in such a way that the opening size is always kept smaller than the soil particle hence, prevents soil from passing through the geo textile.

Technologies for faster construction

“Infrastructure development is the need of the hour for the Indian economy. Construction of bridges is at core of any development for roads, railways and metro rail. Modern bridge construction demands technologies, which are faster, safe and innovative,” says Raj Lakhani, Managing Director, PERI (India) Pvt Ltd.

PERI has developed ground breaking formwork and scaffolding technologies, which continues to set standards in the industry. NHAI has constructed six lane highway over Chambal river. Project includes total 43 piers for bridge with varying height of 27 metre. The pier size at bottom was 7500mmx2500mm and at top is 7000mmx2000mm (i.e. reduction of 500mm) semi-circular at both the end. Also it has limited access to crane as it is over a river. PERI provided solution with hydraulic climbing system RCS along with VARIO formwork system. Customised solution was provided with adaptor in order to climb the system.

Use of precast technologies has helped industry meet high volume requirements and stick to project milestones.

Ratan Lal Kashyap, Sr. Vice President –Procurement, G R Infraprojects Ltd

With the need for less quantity of natural material, use of geosynthetics in flexible pavement sections offer an eco-friendly solution.

Shahrokh Bagli, Chief Technology Officer, Strata Geosystems (India) Pvt Ltd

There are two types of geosynthetics used for the protection of roads and pavements; geogrid and non-woven geotextile.

Kartik Kanodia, Director, Manas Geo Tech India Pvt Ltd

Modern bridge construction demands technologies, which are faster, safe and innovative.

Raj Lakhani, Managing Director, PERI (India) Pvt Ltd

8

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.