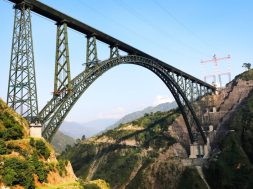

USBRL (Udhampur – Srinagar – Baramulla Rail Link) project will connect Kashmir with rest of India making the journey seamless, hassle free and ensure all-weather connectivity says Kavita Shirvaikar, Director & CFO, Patel Engineering Ltd

Tell us about the T2 project

The Konkan Railway Corporation Limited is currently working on one of the most challenging Indian Railways projects, Udhampur – Srinagar – Baramulla Rail Link (USBRL) Project. The USBRL project, is crucial for the development of Jammu and Kashmir.

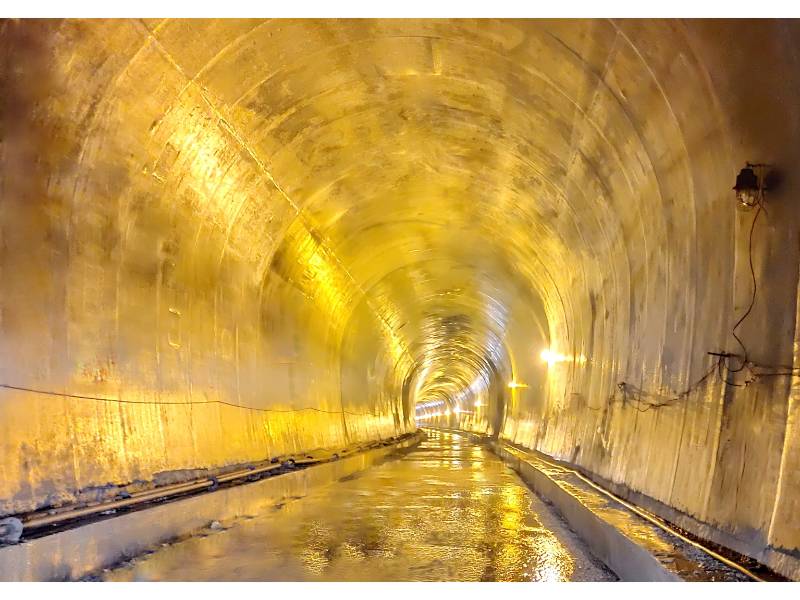

The T2 project involves the construction of Tunnel T- 2 on Katra – Banihal Section of Udhampur – Srinagar – Baramulla New BG Railway Line Project (Package T- 2). The tunnel is a double tube tunnel that consists of the main tunnel of 5.1 km and the escape tunnel parallel to the main tunnel, both tunnels are interconnected by cross passages. This is one of the key packages in USBRL project to connect Kashmir with rest of India making the journey seamless, hassle free and ensure all-weather connectivity. This is one of the ongoing projects Patel Engineering Ltd. is currently involved in.

What were some of the major challenges you had to overcome so far in this project?

The site of the project is remote besides which it is located on a high altitude, so getting the requisite manpower in the lockdown mode was a challenge. Once the lockdown restrictions were eased maintaining the right amount of social distancing was another challenge. The project also brought to the fore numerous geological intricacies owing to its remote location. Extraction and transportation of raw materials required for production of sand and aggregate was a complex task. Besides which moving machinery to the site and ensuring their timely and proper maintenance for maximum uptime too posed as a challenge which we had to address.

Despite the challenges what are some of the key achievements of the T2 project?

Despite the odds we continue to execute the project in a timely manner and our accomplishments so far are a testimony to the fact. In excavation there has been a record overall progress of 477.10 meters from four faces of tunnelling excavation achieved in a single month. A maximum progress of 155.50 m was clocked in, in a time period of one month from P1 MT single face. Keeping in tandem with the task at hand we achieved a maximum progress of 28 meters from four faces in a single day. In overt lining, we planned to achieve a target of 625 meters of tunnel lining in the main tunnel from two faces in one month. The task was challenging and demanded precision expertise to execute. With a team of experienced professionals and young engineers we were able to achieve the target within 21 days. The team was motivated further to create yet another record which resulted in accomplishing a progress of 775 meters in lining the main tunnel. We maintained an average cycle time of 22.5 hours per shutter per month and also had the highest pouring rate of 31.25 cum/hour. In one month our team achieved 250 meters of tunnel lining from a single face and a cumulative of 925 meters from four faces (2 from the main tunnel and 2 from the escape tunnel), this achievement motivated the team to strive for more progress.

How did you offset the different challenges?

The challenges were multi-fold so the ways and methods of tackling them were numerous. Preventive maintenance of all the equipment was carried out to ensure maximum uptime. Monitoring and tracking of the project also involved creation of specific what’s app groups to overcome hindrances and delays and ensure timely decisions. It was equally necessary for us to interact with the workers regularly and keep them motivated, we also provided them with target oriented incentives for their work. The available manpower was utilised for a complete 24-hour work cycle by alternating their working hours whilst ensuring that their recreation time is not compromised.

| Innovative materials and techniques being utilized to execute this project

Layby Shutter

Cross Passage Shutters

Use of Steel Fibre Reinforced concrete

|

Once completed how this project will benefit the common public?

- Connectivity: The completion of this project will provide an all-weather and reliable transportation connectivity to the J&K State through rest of the country by the railway network also provide connectivity by rail to far flung areas of J&K. As this project is the first rail link that will connect the valleys of Kashmir with rest of India. The estimated travel time is saved by 3-4 hours over the current road link between Jammu & Srinagar.

- Employment generation – Direct employment of the local people (about 350) i.e. 80% of total employed and indirect employment of thousands for day to day requirement of the project personnel.

- CSR Initiative – Through CSR initiative many basic facilities are being upgraded in the local areas like school renovation, permanent and temporary drinking water supply system, roads etc.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.