Machine Room-Less (MRL) elevators use up to 80% less energy

Other energy-saving measures include the extensive use of light-emitting diodes (LED) in elevators cabs and escalators, says Mr. Manish Mehan, CEO & MD, TK Elevators

What role can elevators play in aiding a building become net zero carbon building and what initiatives TK Elevator has taken in this regard?

Elevators allow cities to expand upwards instead of outwards, allowing us to effectively reduce urban sprawl and associated negative impacts of traffic congestion, pollution and other key issues that are concerns for many countries in Asia Pacific.

Whether small-scale or skyscraper, buildings account for about 40% of all energy consumed. Especially in urban areas with high-density populations, the use of energy-efficient evaluator systems in sustainable or green buildings is paramount to achieving climate-neutral standards.

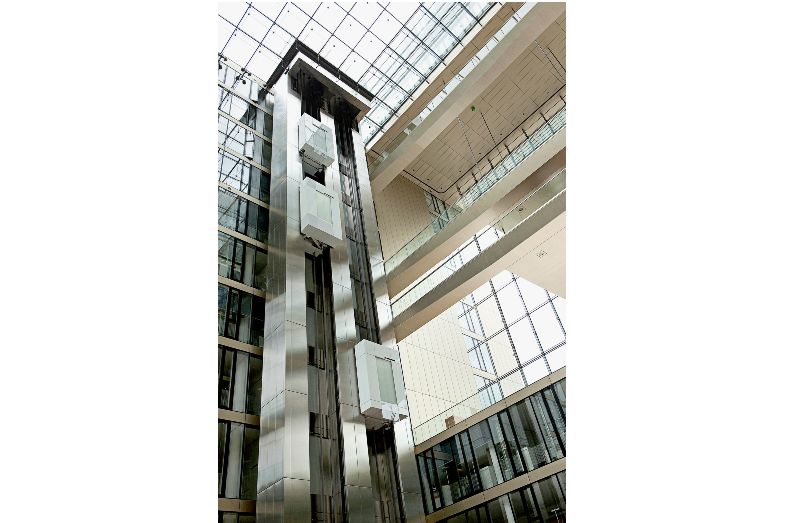

Using TK Elevator’s revolutionary TWIN elevator system as an example, with two elevators operating independently in one shaft, the TWIN offers the benefits of significantly increasing system capacity, without the need for extra elevator shafts.

The biggest advantage of our TWIN is its ability to park one of the two cars while the other stays in operation. This means when passenger volumes are low, very little energy is consumed by the non-moving cars. Additionally, the TWIN can be equipped with energy recovery devices that can feed about 30% of energy back into the building’s power grid.

With sustainability at the core of its business and values, TK Elevator pledges its support at corporate level to two UN initiatives to achieve climate neutrality. “Race to Zero” aims to gain support from all non-state actors for a zero-carbon recovery. “Business Ambitions for 1.5°C” is a call to action for companies to ensure their emissions will match with the 1.5°C goal.

What are the critical changes in design of elevators and its components to make them energy efficient?

New innovations are leading to the introduction of energy efficient elevators that not only consume less energy, but also produce clean energy. New technologies and best practices involving motors, regeneration converters, control software, optimization of counterweights and cabin lighting can yield significant energy savings. New elevators provide efficiency gains of about 30–40 percent than buildings with older lifts. Likewise, Machine Room-Less (MRL) elevators are likely to use up to 80% less energy than hydraulic lifts without oil-filled underground cylinders’ outlay and environmental hazards.

Furthermore, one of the key features of the energy efficient elevators is deployment of permanent magnet synchronous (PMS) gearless traction machines, which consume significantly less energy than conventional geared machines and usage of regenerative drive technology. This feeds energy back into the building’s power grid during the motor’s generative mode (when the car is lightly loaded and moving up, or heavily loaded and moving down). Other energy-saving measures include the extensive use of light-emitting diodes (LED) in elevator cabs and escalators, which can offer up to 80% energy savings versus conventional lighting, while providing the same luminance as traditional lights and a lifetime 10 times longer. LED lights also emit low heat and minimal radiation.

As an innovation leader in the industry, TK Elevator will focus on its digital offerings to help our customers achieve more sustainable building design. AGILE Destination Control is one of our key offerings to make this possible. AGILE is designed to work with new installation or modernization projects, enabling elevators old or new to be deployed more intelligently and flexibly, not only saving energy consumption by optimizing elevator deployment during peak and non-peak hours, AGILE also effectively provide passengers with a better travel experience by reducing waiting and travelling time.

What are some of the energy efficient elevator solutions in your product portfolio?

TWIN, our fast and energy efficient elevator system comes equipped with intelligent traffic control, which optimizes traffic automatically and reduces empty runs. This state-of-the-art system has two cabs running independently in the same shaft, each with its own counterweight, safety and drive equipment. With reduced shaft core space and construction costs, the TWIN elevator system offers the most flexible elevator solution with an eco-conscious heart.

TK Elevator’s ground breaking rope-free elevator system, “MULTI” harnesses the power of linear motor technology to move multiple cars in a single shaft both vertically and horizontally.

MULTI consolidates multiple carriages into fewer shafts. It reduces the elevators’ footprint by up to 50% while increasing passenger throughput by at least as much. MULTI also helps reduce the building’s overall size, external surface area and total energy consumption.

Likewise, TK Elevator’s AGILE Destination Control (DSC) improves system and energy efficiency. Compared to conventional elevator control systems, the AGILE DSC increases passenger handling capacity by up to 30%. DSC also allows for much more flexibility in elevator grouping, lift core layouts and overall building design.

Not to mention, TK Elevator’s, “MAX”, which is a game-changing predictive and pre-emptive maintenance solution extends remote monitoring capabilities to dramatically increase current availability levels of existing and new elevators. Utilizing the power of Internet of Things (IoT) technology, MAX predicts maintenance issues before they occur, and empowers elevator engineers by flagging the need to replace components and systems before the end of their lifecycle.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

Comment(1)

Comments are closed.