ACC helps building for the future

ACC is committed to its group Lafarge Holcim ‘LH 2030 Plan – Build for Tomorrow,’ where the vision for 2030 is to have one-third of our turnover from solutions we sell with enhanced sustainability performance.

Pralhad Mujumdar, Chief Executive Officer- ACC Concrete & B2B Business

Recent performance of construction industry in India

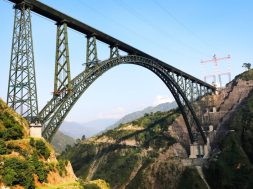

“Due to the focussed government policies and the thrust of smart cities, the construction industry in India has been booming,” says Pralhad Mujumdar, Chief Executive Officer- ACC Concrete and B2B Business. Several infrastructure projects such as roads, metros, and airports, are in pipeline to continue the momentum for the next decade. Major demand is expected from the mid and high rise segment, particularly for slum development and rehabilitation projects. ACC has been signing multiple contracts for power projects, metro works, and commercial spaces such as industries, factories, malls, and software parks, he adds.

Role of technology and solutions in making sustainable structures

Mujumdar says, “ACC is a part of LafargeHolcim Group, which enables the company to leverage on technical support and global expertise on new technology in the field of construction. We also have a strong backup of a world-class research centre at Lyon, France, thus ensuring best-in-class solutions, making it the leading choice when it comes to construction solutions.”

The company has a very robust and mature quality control system deployed across its PAN India operations. Each cluster has a full-fledged central quality lab to execute raw material analysis and mix design evaluation. The inspection and testing plan we have implemented requires scrupulous checks at different stages in production of concrete to ensure reliable product quality across all locations. Mix designs used in production are approved and controlled by a central desk in research and development lab in Thane, ensures compliance with all pertinent standards and product performance expectations, he informs.

Most of its commercial plants are certified by QCI (Quality Council of India) appointed auditors for the ‘Ready Mixed Concrete Manufacturing Capability Certification Scheme’ right from the inception of the scheme, he further adds.

Promising solutions for the future

“ACC is committed to its group Lafarge Holcim ‘LH 2030 Plan – Build for Tomorrow,’ where the vision for 2030 is to have one-third of our turnover from solutions we sell with enhanced sustainability performance,” says Mujumdar.

ACC’s products are aimed at enhanced durability and are hence less prone to early repairs. ACC is perceived as more of a concrete solutions provider rather than a mere concrete supplier. The company has a wide range of solutions to cater the needs of challenging construction problems. There is a range of decorative solutions for architects in the form of imprintcrete and colourcrete. It also offers sustainable solutions in the form of permecrete and ecocrete, which are aimed at ground water conservation and long term durability of concrete, respectively. ACC Ecocrete is an environmentally friendly and sustainable concrete solution with many high performance concrete characteristics built in it; it uses a high amount of supplementary materials which are waste products of other industries. Ecocrete has improved resistance to aggressive environments; the product can be used in chemically sensitive applications resulting in more durable structures, asserts Mujumdar

ACC Permecrete facilitates water conservation in all types of campuses and building societies by facilitating conservation of water by allowing free percolation of water through it without the properties of concrete being compromised. ACC is well known as one of the best solution providers to mid and high rise towers. Supercrete and Supercrete HS, are the most sought after solutions which are high strength and high performance concrete for high rise construction. Flowcrete is another solution for architects and engineers aimed towards the best finishing for structures having congested reinforcements. It facilitates enhancement of site productivity and significantly reduces the noise level, thanks to its self consolidating properties. The company also have Neev, Aadhar, and Suraksha, for footings, columns, and slabs, respectively, aimed at individual house builders and other smaller construction projects, he says.

These products have better properties compared to the generic grades of concrete available in the market. Road construction is another segment where we provide a number of solutions in the form of UTWT, UTWT-8, and UTWT-24, Supercoat and Supercoat Premium. Our concrete allied products – Accoplast and Accofix (Thin bed joining mortar) simplify the mortar application process leading to a cost effective, easy to handle, and time saving solution, informs Mujumdar.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.