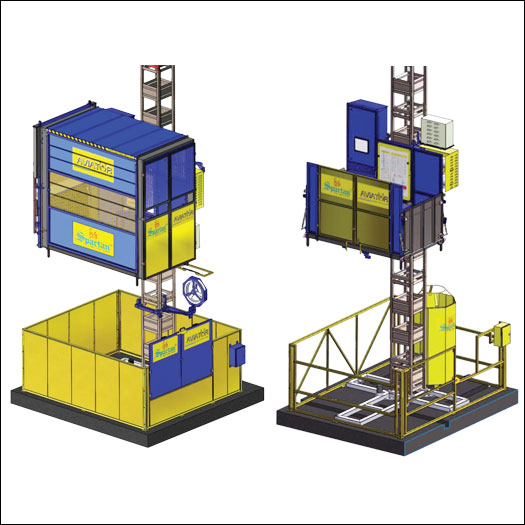

Spartan, with its rich experience in manufacturing hoists, has various models of passenger and material hoists. The recently launched hoists series are branded by ‘Aviator’ series of passenger and material hoists. The weight carrying capacity varies from 500-kg to 2-tonne. These machines are used at both medium and high-rise structures.

Spartan’s multi-functional hoist replaces tower crane for rebar lifting application. It has a rebar carrying attachment which carries rebar measuring 12 metres through horizontal rebar attachment. Spartan also plans to manufacture twin cage hoists in coming year and is at design stage. It also manufactures Rope Suspended Platforms, popularly known as Gandola which is used for various finishing applications like plastering, putty application and painting at the end of the project.

Design upgradations and developments

Spartan has always believed and delivered the best designs when it comes to construction equipment, not only in the aesthetics but also design as in durability, ruggedness and performance. Spartan boasts of around 30 in-house design professionals and is well equipped with all the necessary design software and tools like SolidWorks etc. Each machine is manufactured after rigorous design stage, where best machines of the world in the similar capacity is researched, studied and then designed to match the international standards. FEA analysis is carried out well in advance while designing, where machines are tested at various heights, at adverse climatic conditions through software. This gives a near to actual performance of the machine even before manufacturing. Each machine is designed considering its application, site conditions, safety, convenience, ease in operation etc.

Safety features in Spartan products

Spartan’s hoists come with centrifugal safety device which activates by centrifugal force and stops the hoist in case the hoist’s speed exceeds a specific speed limit. Control Panel in the hoist is one of the most advanced features of Spartan hoists – it is provided with flash light for easy visibility, joystick for easy operation and emergency switches. The PLC functions cover lot of indicators like VFD trip, limit switch failure, phase failure exit door, open entry door, rack search fault etc. The higher or premium models also have display screens where the actual fault would be displayed for easy identification and repair. It is placed at a strategic position which would be easily viewed by the operator. These machines also come with mechanical lock and electrical sensors in critical areas like entry and exit door, trap door, erection platform etc. This ensures hoist does not start if any door is left open. To add to these, overload alarm indicator is also provided as an option.

All these safety features makes Spartan’s hoists more reliable and competitive. Its Rope Suspended Platforms also come with various safety features like anti-swing device that holds on the SRP and avoids swinging of SRP at higher heights and ensures operator’s safety. Spartan’s SRP also comes with roof attachment where the SRP and the operator is safe from the falling debris or material from top while working.

Sparsh Hoist Training Meet in Mumbai

Recently Spartan conducted Sparsh Hoist Training Meet at its Ambernath factory, Mumbai. Around 110 people included Operators, Safety Officers, Third Party Inspectors, Purchase Heads and P&M Heads from various construction companies across Mumbai attended the event. On this occasion, the company has introduced soon to be launched’ Multifunctional Mini Lift (SML 100) along with attachments and features.

Authored by__

Dr. Vikram Mehta,

Managing Director,

Spartan Engineering Industries Pvt Ltd

4

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.