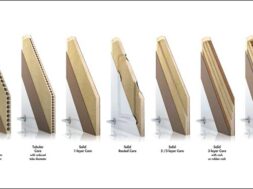

WTF formwork for lowest cost monolithic constructionGCI Wall Forms, the exclusive representative of Wall-Ties & Forms Inc. (WTF), made possible aluminium forms to usher in monolithic constructionMonolithic construction is defined as the pouring of concrete grade beam and floor slab together to form a building. A number of factors came into play to enable monolithic construction to become a reality. The phenomenal growth of India is a key factor.Estimates made by the Technical Group, Ministry of Housing and Urban Poverty Alleviation, the Government of India, the total urban housing shortage in the country was 24.71 million at the end of 2012.Growing trends• Fast-changing demographics and increased migration from rural to urban areas• Urbanisation is calling for improvements in efficiency, productivity and delivery schedules• Extreme shortage of qualified labour with the exploding growth of projects• Globalisation has made available new buildings materials, construction systems and technologies• Fast-depleting natural resources and the need to go green force the judicious use of materials.Advent of aluminium forms technologyThe introduction of aluminium form work into the construction industry has changed the way buildings are constructed. There are a number of different shuttering systems that have been used in the industry over the years. These include timber, steel, plastic and aluminium.Comparison of various shuttering materialsThe introduction of aluminium form work into the construction industry has changed the way buildings are constructed. There are a number of different shuttering systems that have been used in the industry over the years. These include timber, steel, plastic and aluminium.A study was done comparing these different shuttering materials against multiple criteria ranging from availability to resale value.The chart indicates their qualities in green and red colours. Green indicates that they meet or exceed the requirements. Red indicates they do not meet the requirements. As it can be seen aluminium out performs all other materials in all categories.Benefits of WTF aluminium forming systemsThe aluminium forms by Wall-Ties & Forms offer a number of advantages. These are:• Lasts for over 20 years without losing its shape and properties• Provides over 8,000 of repetitions• Allows 1-3 day construction cycles versus 10-15 day cycles with other forms• Requires 85 per cent less labour than traditional construction• Consumes 60 per cent less steel than traditional construction.

Aluminium forms made it possible to usher in monolithic construction.

Monolithic concrete technology requirements• Needs an effective ready-mix concrete that allows early de-shuttering of the forms• There should be enough concrete to complete pouring of the slabs, walls, windows and doors in a single pour• A cost-effective system that allows easy and speedy setting of the Form work• Requires an efficient process that integrates manpower and technology.WTF forms benefits• WTF forms preserve investment for over 20 years• 75-80 per cent of the forms are usually walls and slabs and can be reused over the next 20 years• 20-25 per cent of the forms that vary with clients’ design will be custom manufactured by WTF• The forms are guaranteed for a 1,000 repetitions• Provides an excellent and consistent quality by providing a tolerance of 0.125 mm.Benefits for monolithic construction• All walls, slabs, doors and windows including architectural features are cast in a single pour.• An entire house will be completed in 1-3 days including the external architectural features, water and sewage pipes and electrical conduit• Builders will be able to reduce their operating costs from the usual 10-15 days to 1-3 days• This represents a 70 per cent savings in overall costs like capital costs, labour costs, administrative costs etc. • Houses have no columns and beams• Walls are smooth and require no mortar or plaster• A coat of textured can be optionally applied• Walls can be only 4-inch thick as all walls including partition walls are load bearing members• Steel costs can be up to 60 per cent lower• 4 mm-8 mm steel (rebars) can be used• Buildings are 40 per cent stronger than traditionally constructed houses• Construction costs are 40 per cent lower than traditionally constructed houses• Labour costs are up to 85 per cent lower• Construction process is changed from traditional construction to assembly line manufacturing• Construction process is highly repeatable.WTF aluminium forms offer a real competitive solution to narrow the gap between supply and demand of housing. The technology has been tired and proven by being used for the past 36 years in 55 countries around the world. This technology provides builders an opportunity to sell their properties for 40-50 per cent less than similar properties in the market while completing their housing projects almost 70 per cent faster than building employing other technologies.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.