Wienerberger India takes a major step towards achieving sustainability in its Kunigal factory

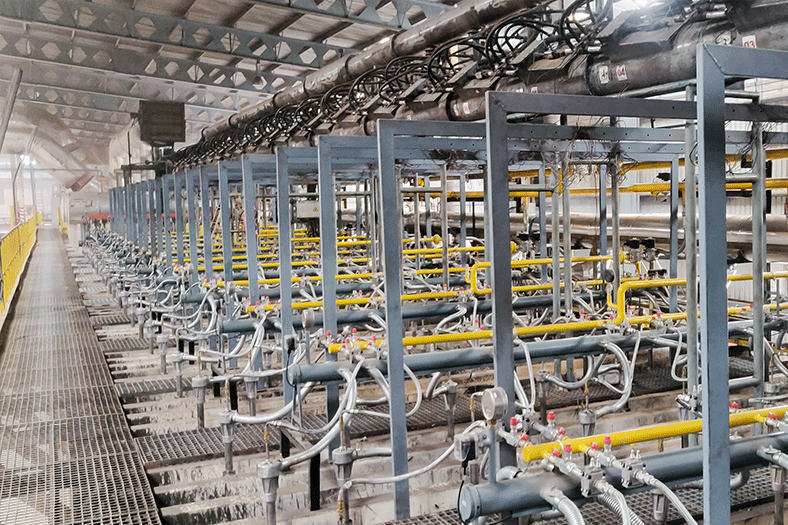

The global provider of building materials and infrastructure solutions will be switching to Natural Gas from conventional solid fuel for the Brick Kiln firing process at its manufacturing unit in Kunigal.

Wienerberger India, has announced that it has gone a step further in its endeavour to achieve sustainability in production by switching to Natural Gas from conventional solid fuel for the Brick Kiln firing process at its factory operations in Kunigal, (70 kms North of Bangalore, Karnataka).

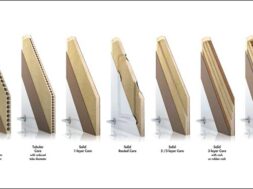

This announcement follows the commitment made by the company in December 2019 on the occasion of its 10th anniversary in India. One of the key investment plans outlined was the conversion to natural gas as a fuel to enable manufacturing of Porotherm Perforated Clay Blocks. Porotherm Smart Bricks are 60 per cent lighter than conventional walling material, thus allowing substantial savings on structural cost due to reduction in dead load. This also allows for faster construction and ease of handling.

Wienerberger AG is consistently pursuing projects that involve converting to low-emission energy sources wherever possible. In 2020, the target has been for the production process in India to be converted from coal to natural gas in line with Wienerberger’s corporate philosophy of providing sustainable solutions to all stakeholders.

The company has already rolled out its new Sustainability Strategy 2020+, which will provide the basis for the sustainability program from 2021 onwards. Decarbonization will be one of the three central action areas.

Benefits of the conversion initiative:

The key benefits of the newer firing technology for its Brick Klin firing (Gas firing) at Wienerberger’s production facility in Kunigal are:

Higher fuel efficiency, reducing Carbon Monoxide emission by > 75%

Reduction in Carbon dioxide emissions by > 40%

Zero Particulate matter emission during firing process

Consistent and higher quality of the fired bricks

The Kunigal factory affirms the usage of Robotics and state-of-the-art technology and has extremely energy-efficient manufacturing processes. The factory is also highly equipped with a full-fledged in-house laboratory and product development facilities.

Elaborating on this conversion, Monnanda Appaiah, Managing Director, Wienerberger India, said, “We are extremely delighted to announce the commissioning of natural gas fuel at our Kunigal factory, which was achieved in a short period of time, despite the challenges brought about by the pandemic. This change in technology will almost eliminate the particulate matters emitted from the kiln during the firing process. We are certain that our Kunigal factory emission norms will match world class norms in emission and would be substantially better than the emission norms laid out as per the Indian environmental standards. Apart from the positive contribution to the environment, health & safety of our employees and the communities in the vicinity, we expect our product quality to also improve considerably with this switch over. We believe that the timing is just right for us to further the Wienerberger global Sustainability Strategy 2020+.”

The latest technology for the new installation (Gas firing) is provided by Beralmar Technologic S.A., a European company (Spain), specialized in manufacturing of firing and drying equipment for clay roof tiles and bricks.

For more info, visit:

www.wienerberger.in

7

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.